50cm x 48cm

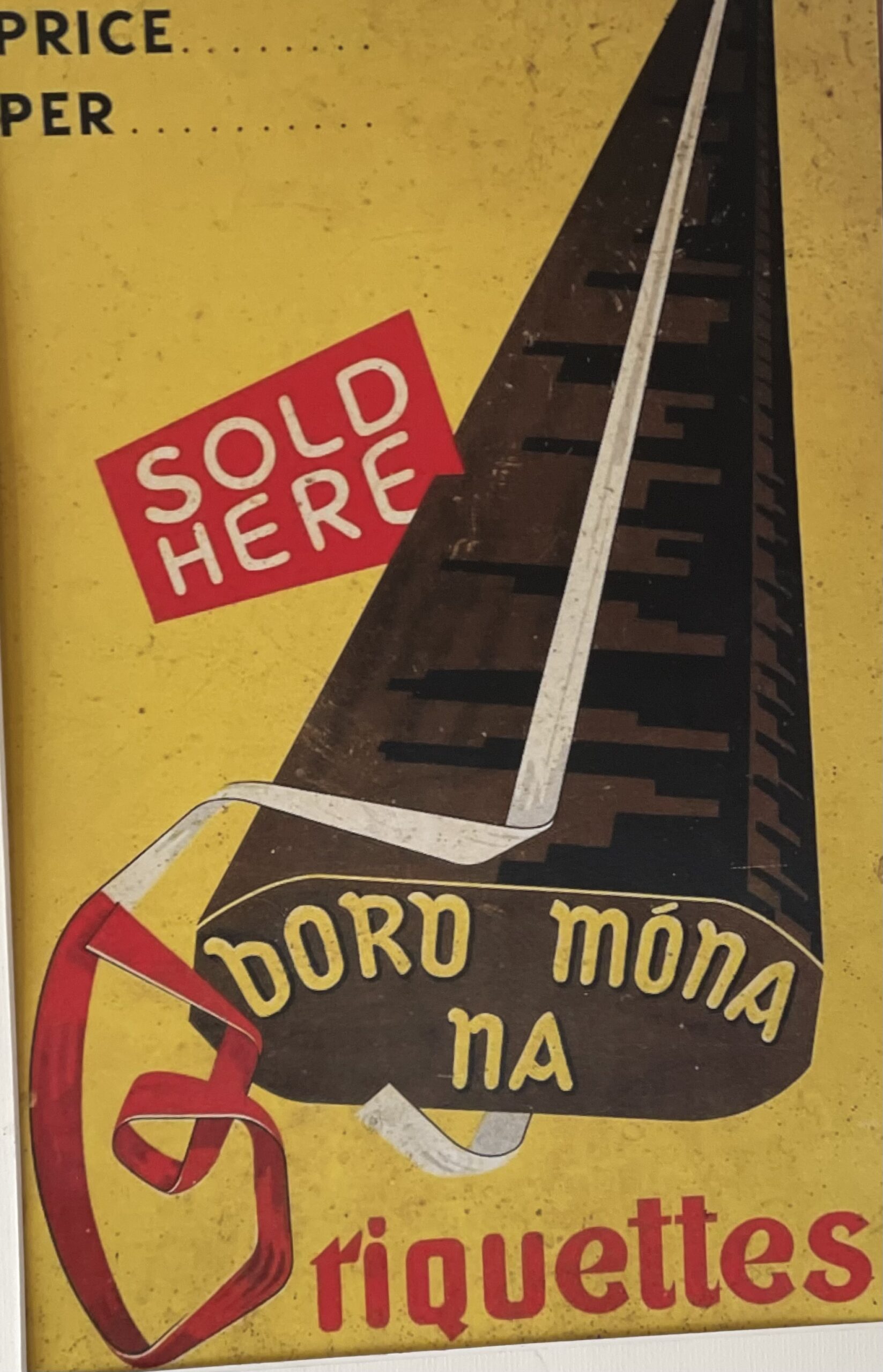

ORD NA MÓNA produces some 315,000 tons of briquettes per annum from 800,000 tons of milled peat. Production takes place at three factories situated at Derrinlough (between Birr and Cloghan), Co. Offaly, Croghan (between Edenderry and Daingean), Co. Offaly, and at Lullymore, Co. Kildare. Lullymore was erected in 1935 and modified extensively in 1957-58, and production is 45,000 tons/annum. Derrinlough followed in 1959 and Croghan in 1961, each producing 135,000 tons/ annum.

There are several descriptions available of earlier attempts at briquetting dried milled peat in Ireland, and of these the most interesting is that by Hodgson (Transactions of I.C.E.1. 1862, and Proceedings of the Inst. of Mech. Engineers 1865) at Derrylea, Co. Offaly. Considerable detail is given in these articles of, not alone Hodgson’s method of winning milled peat on Derrylea bog, but of the erection and operation of the associated briquette factory. Much of the technical data on the process at the time is topical still. Of particular interest is the means by which he dried the peat to 10% m.c. in a 500 foot long scraper dryer, and his development of the string type briquette press claimed to be the progenitor of all subsequent presses as used for brown coal and peat briquetting throughout the world.

Bord na Móna briquettes go to customers in the form of bales (28-lb. bundles), loose or in brickeen form, i.e. single loose briquettes cut into 3 equal parts. These latter are used extensively for industrial boiler applications.

The processing of the milled peat from its arrival in the factory as far as the briquetting and storage stages is shown in the accompanying flow diagram. The data and descriptions which follow refer to the new factories unless otherwise designated.

Following the tippling, blending, fine milling and screening process, it will be seen that the peat tailings are used as fuel in a boiler producing steam at a pressure of 37 atmospheres for a back pressure turbo-alternator of 2,400 kW. maximum output. All power used in the factory is supplied from this source, whilst the low pressure steam at 3 atmospheres passes to the peat dryers. About 9 tons per hour of tailings are used in the boiler, whilst 36 tons per hour of fine peat are conveyed from the screens to the Peco drying process. This system of drying was developed in Scotland during the First World War and the first plant using the system was built near Dumfries. The Peco system is essentially the indirect drying of milled peat by means of hot water and steam while the peat is being pneumatically conveyed in an air/vapour stream. The peat in finely divided form (all through a 10 mm. screen) dries rapidly from its intake moisture-circa 50% m.c.-to 10% m.c. At this moisture content briquettes can be formed under a pressure of some 750 atmospheres in a specially designed press which extrudes the briquettes continuously into cooling runners some 70 metres long. This process is necessary so as to cool and thereby harden the briquettes prior to baling and storage, and to provide steady back pressure on briquettes issuing from the press mouth.

The output of briquettes in the new factories averages 18 tons an hour from an input of 45 tons, or 2.5 to 1 input/output ratio.

Special Equipment

Milled peat as delivered to the briquette factory possesses rather variable physical characteristics in regard to moisture content, bulk density, fibre content, ash content, etc., and there is need to process this variable feed material to make it suitable for manufacturing a finished product of minimum variation from fixed standards.

To this end a number of special pieces of equipment have been developed and built into each factory:

- Blending Bunker

- Buffer Bunker

- Dryers

- Spiral tubes (dryers)

- Press Prepackers

- Anti-corrosive devices

Blending Bunker

Each day’s factory requirements of milled peat about 1,000 tons – is tippled and conveyed by belt over a 150 metre long x 10 metres wide x 12 metres high concrete box building. The belt runs overhead on the centre line of this building and distributes the milled peat in layer upon layer to a total depth of about 8 metres. Some 200 wagons per day from 3 or more bog piles are blended in this way and a mean value for each of the peat physical characteristics is obtained.

The bog piles of peat have widely different characteristics and blending achieves the following results.

Moisture content -This varies on receipt from 40% to 60%. As far as possible blending is arranged to yield a moisture content of around 50% in the factory supply.

Ash content – In blending peat from bogs of low ash content the target is 1.5% plus/minus 1%, and from higher ash bogs the target is 3% plus/ minus 1% in practice.

Bulk density – As measured at the presses where the peat is both fine and free flowing – the target density is 210 grms/litre from bogs of low general density, and 240 grms/litre from higher density areas. A given blend will vary some 10 grms/litre above and below this target figure during the duration of the blend-1 day. If peat were fed to the factory directly as it came from the bog, then 2-hourly (train load) variations in density from 140 grms/litre up to 350 grms/litre could be expected, making control of the process virtually impossible.

Fibre -Some areas of bog provide milled peat of very high fibre content and this is controlled during the blending operation by dilution to a figure acceptable to the factory process. Some conveyors in the factory have an upper tolerance level for fibre and these conveyors are used as controls. High fibre content restricts peat flow in ducts and chutes and can inhibit output as a result.

Buffer Bunker

Interposed between the blending bunker and the 125 KW. hammer mill is a buffer bunker which is designed to act as the factory feed control. Its floor consists of an infinitely variable speed chain grate to feed milled peat to the factory screens via the hammer mill. This finely regulated feed is necessary in order to present the mill with a steady load and so ensure even and regular comminution. The bunker itself has vertical walls in order to keep the milled peat flowing downwards evenly – particularly when it is in the higher moisture ranges. In the case of narrower bunkers and chutes within the factory the walls have been given negative slopes to aid flow, and are insulated where desirable.

The fully automatic peat removal device in the main blending bunker bites into the milled peat pile in a regular forward motion, but for a variety of reasons the flow of peat to the underground belt conveyor can vary plus/minus 20% or more on the control figure. The buffer bunker is essential in the levelling out of this fluctuation in peat coming from the blending bunker. The forward speed of the blending bunker peat removal device is controlled automatically by upper and lower level indicators in the buffer bunker.

Dryers

The Peco type dryer consists essentially of an upper and lower tube plate set in a shell capable of holding either hot water (as in the first 2 of the 5 dryers in the factory dryer system) or steam (as in the last 3 dryers). Tubes are fitted between the tube plates, and fine peat is blown up through these tubes and dried due to heat transfer from the heating medium surrounding the tubes.

Owing to the fact that the largest peat briquette factories built up to 1958 were for 50,000 tons briquette output, it was necessary to redesign the dryers to suit outputs of 135,000 tons/annum. Dryers for the lower output were some 2 metres diameter by 10 to 12 metres high and with tubes from 38 mm. i.d. to 55 mm. i.d. Throughputs of 8-10 tons per hour were possible but some tube chokage was a recurring factor in operation.

Redesign involved lengthening the dryer to 18 metres high, increasing the diameter to 3 metres, and increasing the tube size to 70 mm. i.d. with consequential increases in all loadings and in the problems associated with the peat feed flow and distribution to the bottom tube plates. After some initial commissioning difficulties in providing the necessary air and air/vapour quantities the dryers performed satisfactorily at throughputs ranging from 18 to 24 tons per hour, depending on input moisture content, density and flow characteristics, of the peat feed.

Dryer Tubes

In order to obtain the highest possible specific evaporation rates from the heated tube area in 5 dryers of the system, it was essential to fit specially designed tubes with a 3-start indented spiral helix a form of rifling. By such means the ascending peat particles are pressed by centrifugal force against the hot walls of the tube and this effectively breaks the adhering air skin flowing at 15 m/sec. parallel with the tube inner surface. As a result heat flows more efficiently from the tube walls to the moisture in the peat.

Press Prepackers

Following initial experiments without any form of prepacking of the dry peat fines just prior to their entry to the ram of the press, it was found essential to fit such a device. Without a pre-packer the maximum thickness of briquette obtainable from a press was 18-21 mm. A simple push type ram prepacker was added above and behind the main press ram in such a way that the peat fines descending into the press chamber were held in a packed condition (approximately 2 to 1 by volume) awaiting the next stroke of the main ram. With this device briquette thickness is controllable up to 40 mm. (or more in the case of higher density peat).

Anti-corrosion

As would be anticipated when dealing with a product which has a pH value of 3.5 in its moistened condition, many problems of corrosion have had to be solved in the briquette factories. Associated with corrosive attack is that of erosion from mineral matter in the peat, and care had to be taken in deciding which form of attack was the predominant one prior to prescribing a solution, as combatant materials are costly.

Amongst the items of plant modified were the press formes or moulds within which the briquettes are formed. Originally made from carbon steel with a life between grindings of about 3 weeks, the use of a stainless die tool steel increased forme life to some 12-26 weeks, depending on the mineral matter content of the peat being briquetted. Apart from the elongation of time between grindings the main gain was the ability to hold a high standard of briquette finish and strength over a much longer period. Many mild steel ducts and cyclones are in use where condensation of vapour caused corrosion the products of which were soft enough to be cleaned off by low level erosion. This erosion exposed the surface to renewed corrosion and the vessels had to be clad internally, or be replaced entirely in stainless steel of suitable quality. An interesting example of this occurred on outdoor cyclones where the supports passed through the heat insulation and were welded to the vessel. A small area of the 6 mm. thick shell of the cyclone where each support was attached was colder than the vapour temperature within the cyclone. Rapid corrosion-erosion of this area showed itself by distortion of the sheeting, and settling of the cyclone. Covering of each small area with 2 mm. stainless steel eliminated further trouble.

Other equipment which required protection against aggressive attack by peat vapour comprised the heat exchanger units and associated vessels and ducting, fan impellors, screw conveyor spirals and troughs etc.

Erosion of the peat inlet ends of the tubes of the dryers was stopped by the insertion of 100 mm. lengths of Yorcoron CuNiFeMn alloy tubing.

Boiler Plant

The boilers in all three factories are pulverised peat fired type with steam outlet conditions of 37 atmospheres pressure and 425°C. temperature. Derrinlough and Croghan boilers are of 20 tons/hr. and Lullymore is 10 tons/hr. output. Each is operated for 7,200 hours per annum and is shut for maintenance every 2,000 hours. Steady and continuous running help to reduce wear and tear and the blended peat supply helps greatly to this end.

Turbine Alternator

A 2,400 kW. 3000 r.p.m. Stal radial flow back pressure set is installed at both Derrinlough and Croghan factories. Inlet steam pressure is 35 atmospheres and back pressure is 0.2-3 atmospheres. Generation is at 220/380 volts, 50 cycles. The turbo alternator at Lullymore is a Metropolitan Vickers 1,000 kW. B.P. set with similar inlet and outlet conditions to the other sets. Condensers are used to return unwanted steam to the hot well.

Pressing, Baling and Storage

The briquette presses are 7″ twin type supplied by Buckau Wolf and without the tongue adjustment which is a usual fixture on brown coal presses.

Each press flywheel is of 7 tons weight and the short centred drive is by flat extramultus type belt. There are 5 such presses in each of the larger factories.

The crankshaft is 180 degree two throw and press speed is variable in the range 40-80 r.p.m. normal operation being about 70 r.p.m. The motor is commutator type 3 phase, size 160/80 kW. 540/270 r.p.m. and designed to give P.F. improvement on the system. Press operation is continuous for periods up to 3 weeks or longer, between stops for forme, ram, or other routine maintenance.

Baling

Customer preference has increased steadily over the years for briquettes in bales of 28 lbs. weight (12.6 kg.) and these are made up at the end of the cooling runners – a distance of 70 metres from the press, and are strapped on automatic wire baling machines. Storage of bales takes place on flat pallets. Each pallet takes up to 2½ tons and is fork lifted into covered storage to a height of up to 7 metres. Prior to the onset of winter sales this storage of bales can run to 15,000 to 20,000 tons at the larger factories, with perhaps 5,000-10,000 tons of loose briquettes and brickeen stocks. Out loading of these latter from the storage bunkers into lorries is effected by remote control of the special pusher type outloader and the associated underground conveyor belt system. The operator is positioned above the lorry being loaded and can call up the precise amount of briquettes required by the lorryman.

General

Almost all equipment in each of the larger factories is controlled, started or stopped from a central control desk and the necessary safety devices have been incorporated to protect personnel when remote starting is in progress.

The factory operators number six per shift and a 4 shift system is used. Supporting maintenance, loading and supervisory personnel bring the total factory staff to 120 people.