-

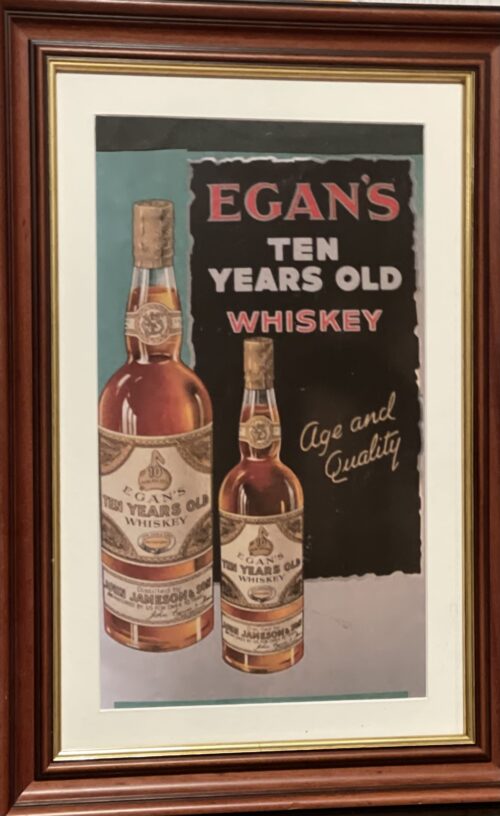

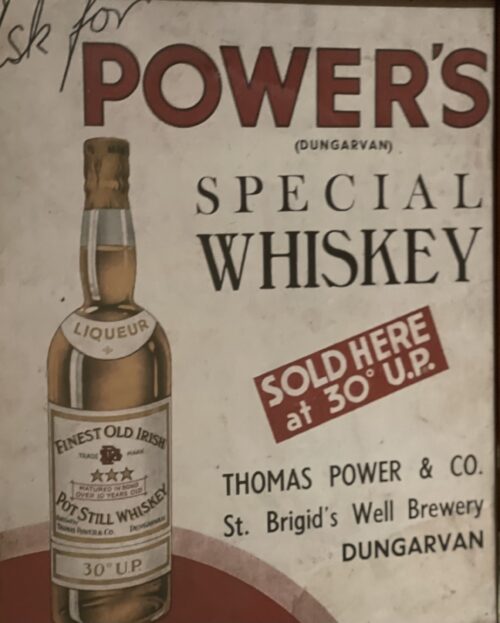

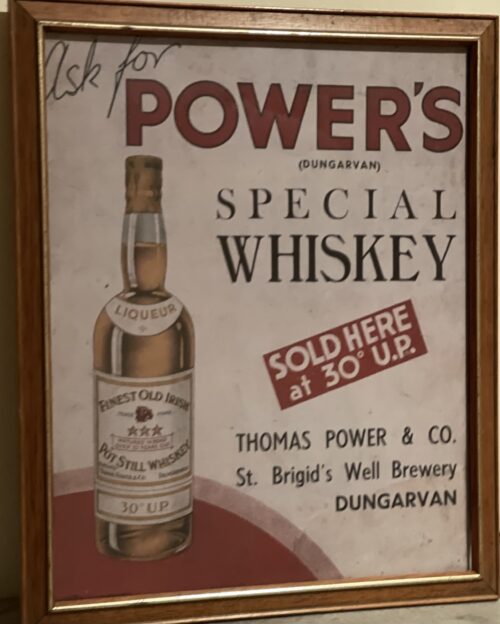

52cm x 44cm Patrick and Henry Egan are perhaps the two brothers whose names are most synonomous with the Tullamore business of P. & H. Egan Ltd. However it was Patrick and Henry’s father, Patrick Egan snr, who first established the business in 1852, and under whose name the company traded in the early years. Egan’s Bridge House, Tullamore, 1852-1968 Patrick Egan snr was born in 1805, the 3rd son of James Egan, a landholder and farmer from Tuarfelim near Moate in Co. Westmeath. Patrick studied law at the King’s Inns and, in 1834, when Daniel O’Connell attended a function to mark the opening of The National Bank in Moate, ‘a young Moate Solicitor named Patrick Egan read an address to O’Connell’. O’Connell would later use his considerable influence to have Egan appointed as the Crown Solicitor for Westmeath. In addition to his burgeoning legal practice, with offices in Moate and at 39 Nassau Street, Dublin, Patrick also set about establishing a number of businesses in Moate, Kilbeggan and Tullamore. The Moate enterprise was a prosperous hardware, grocery and spirit business, which traded as P. Egan & Sons, and was managed by Patrick’s sons William and Luke Egan. The Kilbeggan business was established around 1850 and traded for about thirty years as John Egan & Co. until 1884 when it was sold by P. & H. Egan. In the interim Patrick had also begun to establish himself in the commercial and political life of Tullamore where he was joined by his two eldest sons, Patrick jnr and Henry. Like their father both Patrick and Henry Egan were formidable businessmen whose energetic enterprise have left an indelible mark on the commercial, political and social history of Tullamore. In 1852 P. Egan & Sons began trading from their Bridge House premises as general merchants, provisions, and spirit dealers. The Bridge House business grew exponentially in the early years and by 1882, in addition to a dedicated smoking loft for Irish bacon, Patrick and Henry Egan were also importing bacon directly from America for the wholesale trade. In 1892 ‘the various departments include the choicest growths of teas, general groceries, provisions, Italian warehouse goods, and American and Colonial produce’. In 1866 Egan’s had also acquired an interest in the long established Tullamore Brewery owned by Richard Deverell and in 1869 P. Egan & Sons were soliciting orders ‘for their October Brewings which are in splendid condition’. By 1882 the brewery employed fifty men “drawing not less than £1,600 a year in wages.” They had also acquired ‘a steam saw mill worked by a powerful engine which cuts about 2,000 feet of timber daily’. Between their retail outlet, wholesale department, timber yard and brewery the company employed about one hundred people in 1883. The next thirty-five years represented a golden era for the brewery which produced two porters and four ales while also bottling large quantities of Bass’s ales. Their advertising at this time reflected the family’s staunch nationalist roots: ‘Why consume English and Scotch Ales and Dublin Porter when you have at you door Ales and Stouts brewed equal to the Best of them. Keep the money at home! Ask for Egans Ales and Stouts and Drink no other.’ The brewery would later cease production of porter in order to increase their output of ales while also acting as wholesale bottlers for Guinness and in 1900 they were exporting their beer to Scotland. Patrick and Henry married Elizabeth Moorhead and Lizzie O’Toole, and had large families of nine and twelve children respectively. Outside of their busy family and working lives the brothers were active in politics and were members of the Tullamore Town Commissioners. Henry was also Secretary of the Tullamore Land League. Both Henry and Patrick were ‘on the platform for a monster meeting’ of the Land League in Tullamore on March 17th. 1881. The following month Henry Egan was arrested under the Coercion Act and sent to Naas jail for five weeks. In his absence he was elected Chairman of The Town Commissioners and later became the first Chairman of Offaly County Council in April 1899. Father and Son at Bridge House, Tullamore. Henry Egan (d. 1919) and Patrick Egan (d. 1960). During World War One the Irish brewing industry went into sharp decline and Egan’s was one of the many small breweries which did not survive much beyond the war. By this time the company had diversified and grown considerably both organically and through acquisition. In 1896 P. & H. Egan Ltd. was incorporated with a nominal capital of £80,000. In March of the same year they purchased another long established Tullamore business, Stirling & Co., who were successful spirit wholesalers, retailers and mineral water makers. The acquisition enabled Egan’s to develop a strong mineral water brand which fitted neatly into its existing wholesale offering. In 1908/09 P. H. Egan Ltd had a contract to supply Guinness’ brewery with 28,000 barrels of malted barley from their extensive malt houses in Tullamore and Rathangan. The relationship with Guinness extended over seventy years as suppliers of malted barley and wholesale bottlers of Guinness’ porter. The company continued to transport their malt by canal on barge 42B which Egan’s had commissioned in 1913, until they switched to road transport in 1956. P. & H. Egan also supplied malt to both The Mountjoy Brewery and to John Power’s Distillery. The company were extensive coal merchants and builder suppliers arising out of their saw mill and timber yard. They built a strong agri-business sector supplying farmers with animal feed, seed, fertilizers and agricultural and farm machinery ‘such as ploughs, harrows, grubbers, etc’. This ‘one stop shop’ model was extended beyond The Bridge House and Tullamore as Egan’s sought to expand by developing a network of over sixteen shops and licensed premises, or ‘branch houses’, in towns and villages through five midland counties. They also acquired three hotels including Colton’s and Hayes’ in Tullamore, and Dooly’s Hotel in Birr. In 1919 the company was pleased to announce that Dooly’s Hotel, Duke Square, Birr now has “Hot and Cold Water Baths.” Other shorter lived enterprises included coach and trap building, cycle manufacturing and as contractors for the erection of haybarns, iron railings, and bridges. At the height of the company’s development it is estimated that the firm employed about three hundred people. The house most associated with the Egan family in Tullamore is Acres Hall where Patrick Egan took up residence around 1890. After Patrick’s death in 1897 his brother, Henry, lived in the house until his death in 1919. Patrick’s only son, Francis, who was a minor when his father died, later moved back into the house with his wife, Helen Byrne, and their young family. The house remained in the Egan family until the 1980s. Henry’s eldest son, Pat, became managing director in the early 1900s and in due course Chairman of P. & H. Egan Ltd. In 1919 he purchased the George Hadfield designed Annaghmore House together with 400 acres of land and later successfully contested the 1923 general election in Laois-Offaly for the Cumann na nGaedheal party. Pat’s brothers variously joined the family firm, emigrated and went to war. As wine and spirit merchants, original bonders and bottlers of many Irish whiskeys, including John Jameson, Egan’s developed an extensive wholesale whiskey trade both domestically and for export. Indeed P. & H. Egan produced their own blended whiskeys which included Egan’s No 8. and the more expensive Egan’s No. 5 which they sold by the gallon, and by the dozen in quarts, bottles, pints, half-pints and naggin. At this time they were also importing large quantities of sherry, port and rum for bottling and wholesale. Egan’s Pale Rich sherry, Egan’s EEE Port, Egan’s 3 Star Port and Egan’s 1 Star Port were among the twenty-three ports and sherries on offer from the company. A price list from 1948 gives details of over eighty spirits available from P. & H. Egan’s wholesale department in addition to Cairnes ale, Smithwicks ale and Guinness’s porter, also; ‘tea, wine and brandy shippers, whiskey bonders, manufacturers of premier mineral waters, wholesale bottlers, maltsters, provision merchants, corn buyers and millers, builder’s providers, hardware, sawmills, iromongery, furniture, seeds and manure, grower and exporters of seed potatoes. Head Office and Brewery at Tullamore. Branches at – Ardagh, Ballycumber, Banagher, Ballycommon, Clonaslee, Castletown, Foigha, Ferbane, Kilcormac, Kinnity, Moyvore, Newtowncashel, Rathangan, Riverstown, Tubber’. A price list with list of branches in the 1940s In 1944 the Directors of P. & H. Egan Ltd included Pat Egan (Chairman), Larry Egan (Managing Director), Francis Egan, Michael Kelly, Frank Slattery and Danny Lynam. The company continued to trade successfully for another twenty-five years until the firm finally entered voluntary liquidation in 1968 after one hundred and sixteen years in business.

52cm x 44cm Patrick and Henry Egan are perhaps the two brothers whose names are most synonomous with the Tullamore business of P. & H. Egan Ltd. However it was Patrick and Henry’s father, Patrick Egan snr, who first established the business in 1852, and under whose name the company traded in the early years. Egan’s Bridge House, Tullamore, 1852-1968 Patrick Egan snr was born in 1805, the 3rd son of James Egan, a landholder and farmer from Tuarfelim near Moate in Co. Westmeath. Patrick studied law at the King’s Inns and, in 1834, when Daniel O’Connell attended a function to mark the opening of The National Bank in Moate, ‘a young Moate Solicitor named Patrick Egan read an address to O’Connell’. O’Connell would later use his considerable influence to have Egan appointed as the Crown Solicitor for Westmeath. In addition to his burgeoning legal practice, with offices in Moate and at 39 Nassau Street, Dublin, Patrick also set about establishing a number of businesses in Moate, Kilbeggan and Tullamore. The Moate enterprise was a prosperous hardware, grocery and spirit business, which traded as P. Egan & Sons, and was managed by Patrick’s sons William and Luke Egan. The Kilbeggan business was established around 1850 and traded for about thirty years as John Egan & Co. until 1884 when it was sold by P. & H. Egan. In the interim Patrick had also begun to establish himself in the commercial and political life of Tullamore where he was joined by his two eldest sons, Patrick jnr and Henry. Like their father both Patrick and Henry Egan were formidable businessmen whose energetic enterprise have left an indelible mark on the commercial, political and social history of Tullamore. In 1852 P. Egan & Sons began trading from their Bridge House premises as general merchants, provisions, and spirit dealers. The Bridge House business grew exponentially in the early years and by 1882, in addition to a dedicated smoking loft for Irish bacon, Patrick and Henry Egan were also importing bacon directly from America for the wholesale trade. In 1892 ‘the various departments include the choicest growths of teas, general groceries, provisions, Italian warehouse goods, and American and Colonial produce’. In 1866 Egan’s had also acquired an interest in the long established Tullamore Brewery owned by Richard Deverell and in 1869 P. Egan & Sons were soliciting orders ‘for their October Brewings which are in splendid condition’. By 1882 the brewery employed fifty men “drawing not less than £1,600 a year in wages.” They had also acquired ‘a steam saw mill worked by a powerful engine which cuts about 2,000 feet of timber daily’. Between their retail outlet, wholesale department, timber yard and brewery the company employed about one hundred people in 1883. The next thirty-five years represented a golden era for the brewery which produced two porters and four ales while also bottling large quantities of Bass’s ales. Their advertising at this time reflected the family’s staunch nationalist roots: ‘Why consume English and Scotch Ales and Dublin Porter when you have at you door Ales and Stouts brewed equal to the Best of them. Keep the money at home! Ask for Egans Ales and Stouts and Drink no other.’ The brewery would later cease production of porter in order to increase their output of ales while also acting as wholesale bottlers for Guinness and in 1900 they were exporting their beer to Scotland. Patrick and Henry married Elizabeth Moorhead and Lizzie O’Toole, and had large families of nine and twelve children respectively. Outside of their busy family and working lives the brothers were active in politics and were members of the Tullamore Town Commissioners. Henry was also Secretary of the Tullamore Land League. Both Henry and Patrick were ‘on the platform for a monster meeting’ of the Land League in Tullamore on March 17th. 1881. The following month Henry Egan was arrested under the Coercion Act and sent to Naas jail for five weeks. In his absence he was elected Chairman of The Town Commissioners and later became the first Chairman of Offaly County Council in April 1899. Father and Son at Bridge House, Tullamore. Henry Egan (d. 1919) and Patrick Egan (d. 1960). During World War One the Irish brewing industry went into sharp decline and Egan’s was one of the many small breweries which did not survive much beyond the war. By this time the company had diversified and grown considerably both organically and through acquisition. In 1896 P. & H. Egan Ltd. was incorporated with a nominal capital of £80,000. In March of the same year they purchased another long established Tullamore business, Stirling & Co., who were successful spirit wholesalers, retailers and mineral water makers. The acquisition enabled Egan’s to develop a strong mineral water brand which fitted neatly into its existing wholesale offering. In 1908/09 P. H. Egan Ltd had a contract to supply Guinness’ brewery with 28,000 barrels of malted barley from their extensive malt houses in Tullamore and Rathangan. The relationship with Guinness extended over seventy years as suppliers of malted barley and wholesale bottlers of Guinness’ porter. The company continued to transport their malt by canal on barge 42B which Egan’s had commissioned in 1913, until they switched to road transport in 1956. P. & H. Egan also supplied malt to both The Mountjoy Brewery and to John Power’s Distillery. The company were extensive coal merchants and builder suppliers arising out of their saw mill and timber yard. They built a strong agri-business sector supplying farmers with animal feed, seed, fertilizers and agricultural and farm machinery ‘such as ploughs, harrows, grubbers, etc’. This ‘one stop shop’ model was extended beyond The Bridge House and Tullamore as Egan’s sought to expand by developing a network of over sixteen shops and licensed premises, or ‘branch houses’, in towns and villages through five midland counties. They also acquired three hotels including Colton’s and Hayes’ in Tullamore, and Dooly’s Hotel in Birr. In 1919 the company was pleased to announce that Dooly’s Hotel, Duke Square, Birr now has “Hot and Cold Water Baths.” Other shorter lived enterprises included coach and trap building, cycle manufacturing and as contractors for the erection of haybarns, iron railings, and bridges. At the height of the company’s development it is estimated that the firm employed about three hundred people. The house most associated with the Egan family in Tullamore is Acres Hall where Patrick Egan took up residence around 1890. After Patrick’s death in 1897 his brother, Henry, lived in the house until his death in 1919. Patrick’s only son, Francis, who was a minor when his father died, later moved back into the house with his wife, Helen Byrne, and their young family. The house remained in the Egan family until the 1980s. Henry’s eldest son, Pat, became managing director in the early 1900s and in due course Chairman of P. & H. Egan Ltd. In 1919 he purchased the George Hadfield designed Annaghmore House together with 400 acres of land and later successfully contested the 1923 general election in Laois-Offaly for the Cumann na nGaedheal party. Pat’s brothers variously joined the family firm, emigrated and went to war. As wine and spirit merchants, original bonders and bottlers of many Irish whiskeys, including John Jameson, Egan’s developed an extensive wholesale whiskey trade both domestically and for export. Indeed P. & H. Egan produced their own blended whiskeys which included Egan’s No 8. and the more expensive Egan’s No. 5 which they sold by the gallon, and by the dozen in quarts, bottles, pints, half-pints and naggin. At this time they were also importing large quantities of sherry, port and rum for bottling and wholesale. Egan’s Pale Rich sherry, Egan’s EEE Port, Egan’s 3 Star Port and Egan’s 1 Star Port were among the twenty-three ports and sherries on offer from the company. A price list from 1948 gives details of over eighty spirits available from P. & H. Egan’s wholesale department in addition to Cairnes ale, Smithwicks ale and Guinness’s porter, also; ‘tea, wine and brandy shippers, whiskey bonders, manufacturers of premier mineral waters, wholesale bottlers, maltsters, provision merchants, corn buyers and millers, builder’s providers, hardware, sawmills, iromongery, furniture, seeds and manure, grower and exporters of seed potatoes. Head Office and Brewery at Tullamore. Branches at – Ardagh, Ballycumber, Banagher, Ballycommon, Clonaslee, Castletown, Foigha, Ferbane, Kilcormac, Kinnity, Moyvore, Newtowncashel, Rathangan, Riverstown, Tubber’. A price list with list of branches in the 1940s In 1944 the Directors of P. & H. Egan Ltd included Pat Egan (Chairman), Larry Egan (Managing Director), Francis Egan, Michael Kelly, Frank Slattery and Danny Lynam. The company continued to trade successfully for another twenty-five years until the firm finally entered voluntary liquidation in 1968 after one hundred and sixteen years in business. -

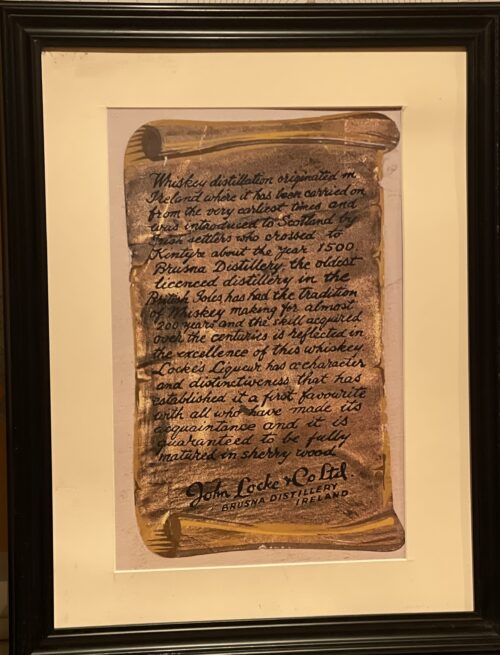

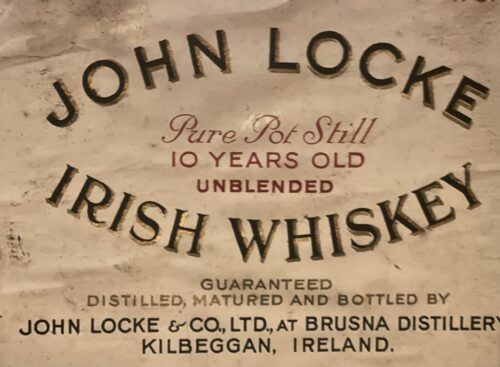

Locke's Old Kilbeggan Pure Pot Still Whiskey Advert Origins: Kilbeggan Co Westmeath Dimensions: 55cm x 45cm The Kilbeggan Distillery (formerly Brusna Distillery and Locke's Distillery) is an Irish whiskey distillery situated on the River Brosna in Kilbeggan, County Westmeath, Ireland. It is owned by Beam Suntory. A small pot still distillery, the licence to distil dates to 1757, a copy of which can be seen in the distillery. Similar to many Irish distilleries, Kilbeggan endured financial difficulties during the early 20th century, and ceased operations in 1957. However, the distillery was later refurbished, with distilling recommencing on-site in 2007. Noted devotees of the distillery's whiskeys include British Prime Minister Sir Winston Churchill, and Myles na gCopaleen, the Irish playwright.

Locke's Old Kilbeggan Pure Pot Still Whiskey Advert Origins: Kilbeggan Co Westmeath Dimensions: 55cm x 45cm The Kilbeggan Distillery (formerly Brusna Distillery and Locke's Distillery) is an Irish whiskey distillery situated on the River Brosna in Kilbeggan, County Westmeath, Ireland. It is owned by Beam Suntory. A small pot still distillery, the licence to distil dates to 1757, a copy of which can be seen in the distillery. Similar to many Irish distilleries, Kilbeggan endured financial difficulties during the early 20th century, and ceased operations in 1957. However, the distillery was later refurbished, with distilling recommencing on-site in 2007. Noted devotees of the distillery's whiskeys include British Prime Minister Sir Winston Churchill, and Myles na gCopaleen, the Irish playwright.Early years

The distillery was founded in 1757 by Matthew MacManus, who may have distilled elsewhere before founding Kilbeggan.Although information about the early years of the distillery is scarce, documentation suggests that in its early years the distillery operated with a 232 gallon still, and an annual output of 1,500 gallons. By the early 19th century, the distillery was being run by a John and William Codd. In 1841, the distillery was put up for sale following the dissolution of the partnership between its then owners, William Codd and William Cuffee.The distillery at the time consisted of a brew house, still house with three pot stills (wash still: 8,000 gallons; low wine still, no. 1; 2,000 gallons; low wine still, no. 2: 1,500 gallons), run-room with five receivers, malt house, corn stores capable of storing 5,000 barrels, and oat-meal mills. Also listed in the sale were 400 tonnes of coal, and 10,000 boxes of turf - the latter reflecting the immense quantities of turf consumed at the distillery, so much so, that it was reported to have kept hundreds of poor people profitably employed in cutting, rearing, and drawing it to the town throughout the year.Locke's Distillery

In 1843, the distillery was taken over by John Locke, under whose stewardship the distillery flourished. Locke treated his staff well, and was held in high regard by both his workers and the people of the town. Informal records show that under Locke the distillery provided cottages for its employees, either for rent or purchase through a form of in-house mortgage scheme. In addition, all staff received a wagon load of coal at the start of each winter, the cost of which was deducted from salaries retrospectively on a weekly basis. Testimony of the respect with which he was held is offered by an incident in 1866. Following an accident on-site which had rendered a critical piece of equipment, the steam boiler, inoperable, the distillery had come to a standstill. With Locke unable to afford or obtain a loan to fund a replacement, the future of distillery lay in doubt.However, in a gesture of solidarity, the people of Kilbeggan came together and purchased a replacement boiler, which they presented to John Locke, along with the following public letter of appreciation, which was printed in several local newspapers at the time:An Address from the People of Kilbeggan to John Locke, Esq. Dear Sir - Permit us, your fellow townsmen, to assure of our deep and cordial sympathy in your loss and disappointment from the accident which occurred recently in your Distillery. Sincerely as we regret the accident, happily unattended with loss of life, we cannot but rejoice at the long-wished-for opportunity it affords us of testifying to you the high appreciation in which we hold you for your public and private worth. We are well aware that the restrictions imposed by recent legislation on that particular branch of Irish industry, with which you have been so long identified, have been attended with disastrous results to the trade, as is manifest in the long list of Distilleries now almost in ruins, and which were a few years ago centres of busy industry, affording remunerative employment to thousands of hands; and we are convinced the Kilbeggan Distillery would have long since swelled the dismal catalogue had it fallen into less energetic and enterprising hands. In such an event we would be compelled to witness the disheartening scene of a large number of our working population without employment during that period of the year when employment Is scarcest, and at the same time most essential to the poor. Independent then of what we owe you, on purely personal grounds, we feel we owe you a deep debt of gratitude for maintaining in our midst a manufacture which affords such extensive employment to our poor, and exercises so favourable an influence on the prosperity of the town. In conclusion, dear Sir, we beg your acceptance of a new steam boiler to replace the injured one, as testimony, inadequate though it is, of our unfeigned respect and esteems for you ; and we beg to present it with the ardent wish and earnest hope that, for many long years to come, it may contribute to enhance still more the deservedly high and increasing reputation of the Kilbeggan Distillery.

In a public response to mark the gift, also published in several newspapers, Locke thanked the people of Kilbeggan for their generosity, stating "...I feel this to be the proudest day of my life...". A plaque commemorating the event hangs in the distillery's restaurant today. In 1878, a fire broke out in the "can dip" (sampling) room of the distillery, and spread rapidly. Although, the fire was extinguished within an hour, it destroying a considerable portion of the front of the distillery and caused £400 worth of damage. Hundreds of gallons of new whiskey were also consumed in the blaze - however, the distillery is said to have been saved from further physical and financial ruin through the quick reaction of townsfolk who broke down the doors of the warehouses, and helped roll thousands of casks of ageing spirit down the street to safety. In 1887, the distillery was visited by Alfred Barnard, a British writer, as research for his book, "the Whiskey Distilleries of the United Kingdom". By then, the much enlarged distillery was being managed by John's sons, John Edward and James Harvey, who told Barnard that the distillery's output had more than doubled during the preceding ten years, and that they intended to install electric lighting.Barnard noted that the distillery, which he referred to as the "Brusna Distillery", named for the nearby river, was said to be the oldest in Ireland. According to Barnard, the distillery covered 5 acres, and employed a staff of about 70 men, with the aged and sick pensioned-off or assisted. At the time of his visit, the distillery was producing 157,200 proof gallons per annum, though it had the capacity to produce 200,000. The whiskey, which was sold primarily in Dublin, England, and "the Colonies", was "old pot still", produced using four pot stills (two wash stills: 10,320 / 8,436 gallons; and two spirit stills: 6,170 / 6,080 gallons), which had been installed by Millar and Company, Dublin. Barnard remarked that at the time of his visit over 2,000 casks of spirit were ageing in the distillery's bonded warehouses. In 1893, the distillery ceased to be privately held, and was converted a limited stock company, trading as John Locke & Co., Ltd., with nominal capital of £40,000.Decline and Closure

In the early part of the 20th century, Kilbeggan, like many Irish whiskey distilleries at the time, entered a period of decline. This was due to the combined effects of loss and hampering of market access - due to prohibition in the United States, the trade war with the British Empire, shipping difficulties during the world wars, and Irish Government export quotas; as well as competition from blended Scotch, and disruption to production during the Irish war of Independence. As a result, Kilbeggan was forced to cease production of new spirit for 7 years between 1924 and 1931, decimating the company's cash flow and finances.Most of the staff at the distillery were let go, and the distillery slowly sold off its stocks of aged whiskey. Distilling resumed in 1931, following the end of prohibition in the United States, and for a time the distillery's finances improved - with a loss of £83 in 1931, converted to a modest profit of £6,700 in 1939. In the 1920s, both of John sons passed away, John in 1920, and James in 1927, and ownership of the distillery passed to Locke's granddaughters, Mary Evelyn and Florence Emily.However, by then the distillery was in need to repair, with the turbulent economic conditions of the early 20th century having meant that no investment had been made in new plant since the 1890s. In 1947, the Lockes decided to put the distillery was put up for sale as a going concern. Although run down, the distillery had valuable stocks of mature whiskey, a valuable commodity in post-war Europe.An offer of £305,000 was received from a Swiss investor fronted by an Englishman, going by the name of Horace Smith.Their unstated interest, was not the business itself, but the 60,000 gallons of whiskey stocks, which they hoped to sell on the black market in England at £11 a gallon - thus, more than doubling their investment overnight. However, when they failed to come up with the deposit, the duo were arrested and promptly interrogated by Irish police. The Englishman, it turned out, was an impostor named Maximoe, who was wanted by Scotland Yard.]The Irish authorities placed Maximoe on a ferry back to England for extradition, but he jumped overboard and escaped with the help of unknown accomplices. An Irish opposition politician, Oliver J. Flanagan, subsequently alleged under parliamentary privilege that members of the governing Fianna Fáil political party were linked to the deal, accusing then Irish Taoiseach Éamon de Valera and his son of having accepted gold watches from the Swiss businessman. A tribunal of inquiry discounted the allegations but the damage contributed to Fianna Fáil's defeat in the 1948 election. In addition, as the scandal remained headline news in Ireland for several months, it discouraged interest from other investors in the distillery. Thus with no buyer found, operations continued at the distillery, with production averaging between 120,000 - 150,000 proof gallons per annum, and consumption running at between 15,000 - 20,000 barrels of barrel.In addition, although heavily indebted, investments were made in new plant and equipment. However, the death knell for the distillery came in April 1952, when the Irish Government introduced a 28% hike in the excise duties on spirits, causing a drastic decline in domestic whiskey sales. By November 1953, the distillery could not afford to pay the duty to release whiskey ordered for Christmas from bond, and production was forced to come to a halt. Although distilling had stopped, the firm struggled on until 27 November 1958, when a debenture issued in 1953 fell due, which the distillery could not afford to pay, forcing the bank to call in the receivers. Thus, bringing to an end 201 years of distilling in the town. In 1962, the distillery was purchased for £10,000 by Karl Heinz Moller, a German businessman, who owned a motor distribution company in Hamburg.Moller made a substantial profit on the deal, by selling off the whiskey stocks (about 100,000 gallons - worth tens of thousands of pounds alone) and a rare Mercedes Benz owned by the distillery. Much to the dismay of locals, Moller proceeded to convert the distillery into a pigsty, smashing thousands of Locke earthenware crocks (which would be worth a substantial amount at auction today) to create a hard-core base for the concrete floor. In 1969, the distillery was sold to Powerscreen, a firm which sold Volvo loading shovels, and in the early 1970s, the stills and worms were removed and sold for scrap.Distillery reopens

In 1982, almost thirty years after the distillery ceased operations, the Kilbeggan Preservation and Development Association was formed by locals in the town. Using funds raised locally, the Association restored the Distillery, and reopened it to the public as a whiskey distillery museum. Then, in 1987, the newly opened Cooley Distillery acquired the assets of Kilbeggan distillery, allowing Cooley to relaunch whiskeys under the Kilbeggan and Locke's Whiskey brands. Cooley later also took over the running of the museum, and began the process of re-establishing a working distillery on-site. Cooley were aided in the process by the fact that since the distillery's closure, each subsequent owner had faithfully paid the £5 annual fee to maintain the distilling licence. In 2007, the 250th anniversary of the distillery's founding, distillation recommenced at Kilbeggan. The official firing of the pot stills was witnessed by direct descendants of the three families, the McManuses, the Codds, and the Lockes, who had run the distillery during its 200 year distilling history. In a fitting nod to the long history of distilling at Kilbeggan, one of the two pot stills installed in the refurbished distillery was a 180-year old pot still, which had originally been installed at the Old Tullamore Distillery in the early 1800s.] It is the oldest working pot still producing whiskey in the world today. In 2010, with the installation of a mash tun and fermentation vats, Kilbeggan became a fully operational distillery once again.Present day

Today the distillery is known as Kilbeggan Distillery, and includes a restaurant, The Pantry Restaurant, and a 19th-century waterwheel that has been restored to working condition. The distillery can also be powered by a steam engine, which is in working condition but rarely used. It was installed to allow the distillery to continue operating in times of low water on the river. Prior to the recommencement of operations of Kilbeggan, the three brands associated with the distillery—Kilbeggan, Locke's Blend and Locke's Malt were produced at the Cooley Distillery in County Louth, before being transported to Kilbeggan, where they were to stored in a 200 year old granite warehouse. However, following recommencement of operations at Kilbeggan, new whiskey produced on-site has been sufficiently mature for market since around 2014. Since reopening, the distillery has launched a Kilbeggan Small Batch Rye, the first whiskey to be 100% distilled and matured on-site since the restoration was completed. Double-distilled, the whiskey is produced from a mash of malt, barley, and about 30% rye, said to reflect the traditional practice of using rye, which was common at 19th century Irish distilleries, but has since virtually died out. In late 2009, the distillery released small '3-pack' samples of its still-developing "new make spirit" at 1 month, 1 year, and 2 years of age (in Ireland, the spirit must be aged a minimum of three years before it can legally be called "whiskey"). The distillery's visitor centre was among the nominations in Whisky Magazine's Icons of Whisky visitor attraction category in 2008.Gallery

-

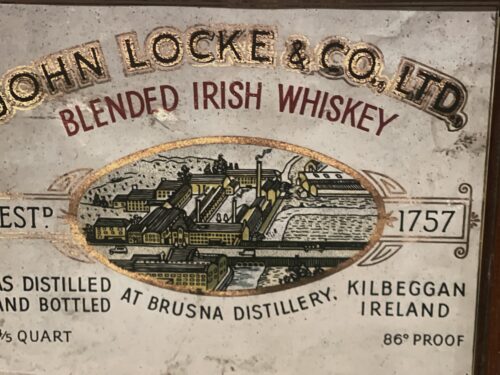

Locke's Old Kilbeggan Pure Pot Still Whiskey Advert Origins: Kilbeggan Co Westmeath Dimensions: 32cm x 37cm The Kilbeggan Distillery (formerly Brusna Distillery and Locke's Distillery) is an Irish whiskey distillery situated on the River Brosna in Kilbeggan, County Westmeath, Ireland. It is owned by Beam Suntory. A small pot still distillery, the licence to distil dates to 1757, a copy of which can be seen in the distillery. Similar to many Irish distilleries, Kilbeggan endured financial difficulties during the early 20th century, and ceased operations in 1957. However, the distillery was later refurbished, with distilling recommencing on-site in 2007. Noted devotees of the distillery's whiskeys include British Prime Minister Sir Winston Churchill, and Myles na gCopaleen, the Irish playwright.

Locke's Old Kilbeggan Pure Pot Still Whiskey Advert Origins: Kilbeggan Co Westmeath Dimensions: 32cm x 37cm The Kilbeggan Distillery (formerly Brusna Distillery and Locke's Distillery) is an Irish whiskey distillery situated on the River Brosna in Kilbeggan, County Westmeath, Ireland. It is owned by Beam Suntory. A small pot still distillery, the licence to distil dates to 1757, a copy of which can be seen in the distillery. Similar to many Irish distilleries, Kilbeggan endured financial difficulties during the early 20th century, and ceased operations in 1957. However, the distillery was later refurbished, with distilling recommencing on-site in 2007. Noted devotees of the distillery's whiskeys include British Prime Minister Sir Winston Churchill, and Myles na gCopaleen, the Irish playwright.Early years

The distillery was founded in 1757 by Matthew MacManus, who may have distilled elsewhere before founding Kilbeggan.Although information about the early years of the distillery is scarce, documentation suggests that in its early years the distillery operated with a 232 gallon still, and an annual output of 1,500 gallons. By the early 19th century, the distillery was being run by a John and William Codd. In 1841, the distillery was put up for sale following the dissolution of the partnership between its then owners, William Codd and William Cuffee.The distillery at the time consisted of a brew house, still house with three pot stills (wash still: 8,000 gallons; low wine still, no. 1; 2,000 gallons; low wine still, no. 2: 1,500 gallons), run-room with five receivers, malt house, corn stores capable of storing 5,000 barrels, and oat-meal mills. Also listed in the sale were 400 tonnes of coal, and 10,000 boxes of turf - the latter reflecting the immense quantities of turf consumed at the distillery, so much so, that it was reported to have kept hundreds of poor people profitably employed in cutting, rearing, and drawing it to the town throughout the year.Locke's Distillery

In 1843, the distillery was taken over by John Locke, under whose stewardship the distillery flourished. Locke treated his staff well, and was held in high regard by both his workers and the people of the town. Informal records show that under Locke the distillery provided cottages for its employees, either for rent or purchase through a form of in-house mortgage scheme. In addition, all staff received a wagon load of coal at the start of each winter, the cost of which was deducted from salaries retrospectively on a weekly basis. Testimony of the respect with which he was held is offered by an incident in 1866. Following an accident on-site which had rendered a critical piece of equipment, the steam boiler, inoperable, the distillery had come to a standstill. With Locke unable to afford or obtain a loan to fund a replacement, the future of distillery lay in doubt.However, in a gesture of solidarity, the people of Kilbeggan came together and purchased a replacement boiler, which they presented to John Locke, along with the following public letter of appreciation, which was printed in several local newspapers at the time:An Address from the People of Kilbeggan to John Locke, Esq. Dear Sir - Permit us, your fellow townsmen, to assure of our deep and cordial sympathy in your loss and disappointment from the accident which occurred recently in your Distillery. Sincerely as we regret the accident, happily unattended with loss of life, we cannot but rejoice at the long-wished-for opportunity it affords us of testifying to you the high appreciation in which we hold you for your public and private worth. We are well aware that the restrictions imposed by recent legislation on that particular branch of Irish industry, with which you have been so long identified, have been attended with disastrous results to the trade, as is manifest in the long list of Distilleries now almost in ruins, and which were a few years ago centres of busy industry, affording remunerative employment to thousands of hands; and we are convinced the Kilbeggan Distillery would have long since swelled the dismal catalogue had it fallen into less energetic and enterprising hands. In such an event we would be compelled to witness the disheartening scene of a large number of our working population without employment during that period of the year when employment Is scarcest, and at the same time most essential to the poor. Independent then of what we owe you, on purely personal grounds, we feel we owe you a deep debt of gratitude for maintaining in our midst a manufacture which affords such extensive employment to our poor, and exercises so favourable an influence on the prosperity of the town. In conclusion, dear Sir, we beg your acceptance of a new steam boiler to replace the injured one, as testimony, inadequate though it is, of our unfeigned respect and esteems for you ; and we beg to present it with the ardent wish and earnest hope that, for many long years to come, it may contribute to enhance still more the deservedly high and increasing reputation of the Kilbeggan Distillery.

In a public response to mark the gift, also published in several newspapers, Locke thanked the people of Kilbeggan for their generosity, stating "...I feel this to be the proudest day of my life...". A plaque commemorating the event hangs in the distillery's restaurant today. In 1878, a fire broke out in the "can dip" (sampling) room of the distillery, and spread rapidly. Although, the fire was extinguished within an hour, it destroying a considerable portion of the front of the distillery and caused £400 worth of damage. Hundreds of gallons of new whiskey were also consumed in the blaze - however, the distillery is said to have been saved from further physical and financial ruin through the quick reaction of townsfolk who broke down the doors of the warehouses, and helped roll thousands of casks of ageing spirit down the street to safety. In 1887, the distillery was visited by Alfred Barnard, a British writer, as research for his book, "the Whiskey Distilleries of the United Kingdom". By then, the much enlarged distillery was being managed by John's sons, John Edward and James Harvey, who told Barnard that the distillery's output had more than doubled during the preceding ten years, and that they intended to install electric lighting.Barnard noted that the distillery, which he referred to as the "Brusna Distillery", named for the nearby river, was said to be the oldest in Ireland. According to Barnard, the distillery covered 5 acres, and employed a staff of about 70 men, with the aged and sick pensioned-off or assisted. At the time of his visit, the distillery was producing 157,200 proof gallons per annum, though it had the capacity to produce 200,000. The whiskey, which was sold primarily in Dublin, England, and "the Colonies", was "old pot still", produced using four pot stills (two wash stills: 10,320 / 8,436 gallons; and two spirit stills: 6,170 / 6,080 gallons), which had been installed by Millar and Company, Dublin. Barnard remarked that at the time of his visit over 2,000 casks of spirit were ageing in the distillery's bonded warehouses. In 1893, the distillery ceased to be privately held, and was converted a limited stock company, trading as John Locke & Co., Ltd., with nominal capital of £40,000.Decline and Closure

In the early part of the 20th century, Kilbeggan, like many Irish whiskey distilleries at the time, entered a period of decline. This was due to the combined effects of loss and hampering of market access - due to prohibition in the United States, the trade war with the British Empire, shipping difficulties during the world wars, and Irish Government export quotas; as well as competition from blended Scotch, and disruption to production during the Irish war of Independence. As a result, Kilbeggan was forced to cease production of new spirit for 7 years between 1924 and 1931, decimating the company's cash flow and finances.Most of the staff at the distillery were let go, and the distillery slowly sold off its stocks of aged whiskey. Distilling resumed in 1931, following the end of prohibition in the United States, and for a time the distillery's finances improved - with a loss of £83 in 1931, converted to a modest profit of £6,700 in 1939. In the 1920s, both of John sons passed away, John in 1920, and James in 1927, and ownership of the distillery passed to Locke's granddaughters, Mary Evelyn and Florence Emily.However, by then the distillery was in need to repair, with the turbulent economic conditions of the early 20th century having meant that no investment had been made in new plant since the 1890s. In 1947, the Lockes decided to put the distillery was put up for sale as a going concern. Although run down, the distillery had valuable stocks of mature whiskey, a valuable commodity in post-war Europe.An offer of £305,000 was received from a Swiss investor fronted by an Englishman, going by the name of Horace Smith.Their unstated interest, was not the business itself, but the 60,000 gallons of whiskey stocks, which they hoped to sell on the black market in England at £11 a gallon - thus, more than doubling their investment overnight. However, when they failed to come up with the deposit, the duo were arrested and promptly interrogated by Irish police. The Englishman, it turned out, was an impostor named Maximoe, who was wanted by Scotland Yard.]The Irish authorities placed Maximoe on a ferry back to England for extradition, but he jumped overboard and escaped with the help of unknown accomplices. An Irish opposition politician, Oliver J. Flanagan, subsequently alleged under parliamentary privilege that members of the governing Fianna Fáil political party were linked to the deal, accusing then Irish Taoiseach Éamon de Valera and his son of having accepted gold watches from the Swiss businessman. A tribunal of inquiry discounted the allegations but the damage contributed to Fianna Fáil's defeat in the 1948 election. In addition, as the scandal remained headline news in Ireland for several months, it discouraged interest from other investors in the distillery. Thus with no buyer found, operations continued at the distillery, with production averaging between 120,000 - 150,000 proof gallons per annum, and consumption running at between 15,000 - 20,000 barrels of barrel.In addition, although heavily indebted, investments were made in new plant and equipment. However, the death knell for the distillery came in April 1952, when the Irish Government introduced a 28% hike in the excise duties on spirits, causing a drastic decline in domestic whiskey sales. By November 1953, the distillery could not afford to pay the duty to release whiskey ordered for Christmas from bond, and production was forced to come to a halt. Although distilling had stopped, the firm struggled on until 27 November 1958, when a debenture issued in 1953 fell due, which the distillery could not afford to pay, forcing the bank to call in the receivers. Thus, bringing to an end 201 years of distilling in the town. In 1962, the distillery was purchased for £10,000 by Karl Heinz Moller, a German businessman, who owned a motor distribution company in Hamburg.Moller made a substantial profit on the deal, by selling off the whiskey stocks (about 100,000 gallons - worth tens of thousands of pounds alone) and a rare Mercedes Benz owned by the distillery. Much to the dismay of locals, Moller proceeded to convert the distillery into a pigsty, smashing thousands of Locke earthenware crocks (which would be worth a substantial amount at auction today) to create a hard-core base for the concrete floor. In 1969, the distillery was sold to Powerscreen, a firm which sold Volvo loading shovels, and in the early 1970s, the stills and worms were removed and sold for scrap.Distillery reopens

In 1982, almost thirty years after the distillery ceased operations, the Kilbeggan Preservation and Development Association was formed by locals in the town. Using funds raised locally, the Association restored the Distillery, and reopened it to the public as a whiskey distillery museum. Then, in 1987, the newly opened Cooley Distillery acquired the assets of Kilbeggan distillery, allowing Cooley to relaunch whiskeys under the Kilbeggan and Locke's Whiskey brands. Cooley later also took over the running of the museum, and began the process of re-establishing a working distillery on-site. Cooley were aided in the process by the fact that since the distillery's closure, each subsequent owner had faithfully paid the £5 annual fee to maintain the distilling licence. In 2007, the 250th anniversary of the distillery's founding, distillation recommenced at Kilbeggan. The official firing of the pot stills was witnessed by direct descendants of the three families, the McManuses, the Codds, and the Lockes, who had run the distillery during its 200 year distilling history. In a fitting nod to the long history of distilling at Kilbeggan, one of the two pot stills installed in the refurbished distillery was a 180-year old pot still, which had originally been installed at the Old Tullamore Distillery in the early 1800s.] It is the oldest working pot still producing whiskey in the world today. In 2010, with the installation of a mash tun and fermentation vats, Kilbeggan became a fully operational distillery once again.Present day

Today the distillery is known as Kilbeggan Distillery, and includes a restaurant, The Pantry Restaurant, and a 19th-century waterwheel that has been restored to working condition. The distillery can also be powered by a steam engine, which is in working condition but rarely used. It was installed to allow the distillery to continue operating in times of low water on the river. Prior to the recommencement of operations of Kilbeggan, the three brands associated with the distillery—Kilbeggan, Locke's Blend and Locke's Malt were produced at the Cooley Distillery in County Louth, before being transported to Kilbeggan, where they were to stored in a 200 year old granite warehouse. However, following recommencement of operations at Kilbeggan, new whiskey produced on-site has been sufficiently mature for market since around 2014. Since reopening, the distillery has launched a Kilbeggan Small Batch Rye, the first whiskey to be 100% distilled and matured on-site since the restoration was completed. Double-distilled, the whiskey is produced from a mash of malt, barley, and about 30% rye, said to reflect the traditional practice of using rye, which was common at 19th century Irish distilleries, but has since virtually died out. In late 2009, the distillery released small '3-pack' samples of its still-developing "new make spirit" at 1 month, 1 year, and 2 years of age (in Ireland, the spirit must be aged a minimum of three years before it can legally be called "whiskey"). The distillery's visitor centre was among the nominations in Whisky Magazine's Icons of Whisky visitor attraction category in 2008.Gallery

-

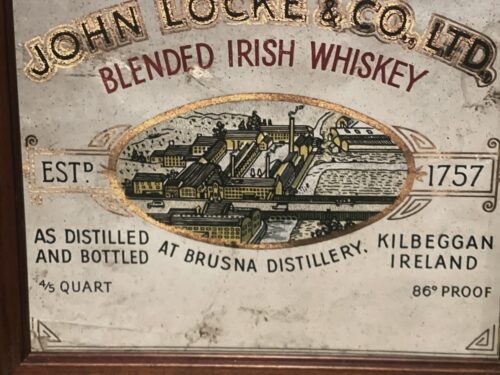

Locke's Old Kilbeggan Pure Pot Still Whiskey Advert Origins: Kilbeggan Co Westmeath Dimensions: 32cm x 37cm The Kilbeggan Distillery (formerly Brusna Distillery and Locke's Distillery) is an Irish whiskey distillery situated on the River Brosna in Kilbeggan, County Westmeath, Ireland. It is owned by Beam Suntory. A small pot still distillery, the licence to distil dates to 1757, a copy of which can be seen in the distillery. Similar to many Irish distilleries, Kilbeggan endured financial difficulties during the early 20th century, and ceased operations in 1957. However, the distillery was later refurbished, with distilling recommencing on-site in 2007. Noted devotees of the distillery's whiskeys include British Prime Minister Sir Winston Churchill, and Myles na gCopaleen, the Irish playwright.

Locke's Old Kilbeggan Pure Pot Still Whiskey Advert Origins: Kilbeggan Co Westmeath Dimensions: 32cm x 37cm The Kilbeggan Distillery (formerly Brusna Distillery and Locke's Distillery) is an Irish whiskey distillery situated on the River Brosna in Kilbeggan, County Westmeath, Ireland. It is owned by Beam Suntory. A small pot still distillery, the licence to distil dates to 1757, a copy of which can be seen in the distillery. Similar to many Irish distilleries, Kilbeggan endured financial difficulties during the early 20th century, and ceased operations in 1957. However, the distillery was later refurbished, with distilling recommencing on-site in 2007. Noted devotees of the distillery's whiskeys include British Prime Minister Sir Winston Churchill, and Myles na gCopaleen, the Irish playwright.Early years

The distillery was founded in 1757 by Matthew MacManus, who may have distilled elsewhere before founding Kilbeggan.Although information about the early years of the distillery is scarce, documentation suggests that in its early years the distillery operated with a 232 gallon still, and an annual output of 1,500 gallons. By the early 19th century, the distillery was being run by a John and William Codd. In 1841, the distillery was put up for sale following the dissolution of the partnership between its then owners, William Codd and William Cuffee.The distillery at the time consisted of a brew house, still house with three pot stills (wash still: 8,000 gallons; low wine still, no. 1; 2,000 gallons; low wine still, no. 2: 1,500 gallons), run-room with five receivers, malt house, corn stores capable of storing 5,000 barrels, and oat-meal mills. Also listed in the sale were 400 tonnes of coal, and 10,000 boxes of turf - the latter reflecting the immense quantities of turf consumed at the distillery, so much so, that it was reported to have kept hundreds of poor people profitably employed in cutting, rearing, and drawing it to the town throughout the year.Locke's Distillery

In 1843, the distillery was taken over by John Locke, under whose stewardship the distillery flourished. Locke treated his staff well, and was held in high regard by both his workers and the people of the town. Informal records show that under Locke the distillery provided cottages for its employees, either for rent or purchase through a form of in-house mortgage scheme. In addition, all staff received a wagon load of coal at the start of each winter, the cost of which was deducted from salaries retrospectively on a weekly basis. Testimony of the respect with which he was held is offered by an incident in 1866. Following an accident on-site which had rendered a critical piece of equipment, the steam boiler, inoperable, the distillery had come to a standstill. With Locke unable to afford or obtain a loan to fund a replacement, the future of distillery lay in doubt.However, in a gesture of solidarity, the people of Kilbeggan came together and purchased a replacement boiler, which they presented to John Locke, along with the following public letter of appreciation, which was printed in several local newspapers at the time:An Address from the People of Kilbeggan to John Locke, Esq. Dear Sir - Permit us, your fellow townsmen, to assure of our deep and cordial sympathy in your loss and disappointment from the accident which occurred recently in your Distillery. Sincerely as we regret the accident, happily unattended with loss of life, we cannot but rejoice at the long-wished-for opportunity it affords us of testifying to you the high appreciation in which we hold you for your public and private worth. We are well aware that the restrictions imposed by recent legislation on that particular branch of Irish industry, with which you have been so long identified, have been attended with disastrous results to the trade, as is manifest in the long list of Distilleries now almost in ruins, and which were a few years ago centres of busy industry, affording remunerative employment to thousands of hands; and we are convinced the Kilbeggan Distillery would have long since swelled the dismal catalogue had it fallen into less energetic and enterprising hands. In such an event we would be compelled to witness the disheartening scene of a large number of our working population without employment during that period of the year when employment Is scarcest, and at the same time most essential to the poor. Independent then of what we owe you, on purely personal grounds, we feel we owe you a deep debt of gratitude for maintaining in our midst a manufacture which affords such extensive employment to our poor, and exercises so favourable an influence on the prosperity of the town. In conclusion, dear Sir, we beg your acceptance of a new steam boiler to replace the injured one, as testimony, inadequate though it is, of our unfeigned respect and esteems for you ; and we beg to present it with the ardent wish and earnest hope that, for many long years to come, it may contribute to enhance still more the deservedly high and increasing reputation of the Kilbeggan Distillery.

In a public response to mark the gift, also published in several newspapers, Locke thanked the people of Kilbeggan for their generosity, stating "...I feel this to be the proudest day of my life...". A plaque commemorating the event hangs in the distillery's restaurant today. In 1878, a fire broke out in the "can dip" (sampling) room of the distillery, and spread rapidly. Although, the fire was extinguished within an hour, it destroying a considerable portion of the front of the distillery and caused £400 worth of damage. Hundreds of gallons of new whiskey were also consumed in the blaze - however, the distillery is said to have been saved from further physical and financial ruin through the quick reaction of townsfolk who broke down the doors of the warehouses, and helped roll thousands of casks of ageing spirit down the street to safety. In 1887, the distillery was visited by Alfred Barnard, a British writer, as research for his book, "the Whiskey Distilleries of the United Kingdom". By then, the much enlarged distillery was being managed by John's sons, John Edward and James Harvey, who told Barnard that the distillery's output had more than doubled during the preceding ten years, and that they intended to install electric lighting.Barnard noted that the distillery, which he referred to as the "Brusna Distillery", named for the nearby river, was said to be the oldest in Ireland. According to Barnard, the distillery covered 5 acres, and employed a staff of about 70 men, with the aged and sick pensioned-off or assisted. At the time of his visit, the distillery was producing 157,200 proof gallons per annum, though it had the capacity to produce 200,000. The whiskey, which was sold primarily in Dublin, England, and "the Colonies", was "old pot still", produced using four pot stills (two wash stills: 10,320 / 8,436 gallons; and two spirit stills: 6,170 / 6,080 gallons), which had been installed by Millar and Company, Dublin. Barnard remarked that at the time of his visit over 2,000 casks of spirit were ageing in the distillery's bonded warehouses. In 1893, the distillery ceased to be privately held, and was converted a limited stock company, trading as John Locke & Co., Ltd., with nominal capital of £40,000.Decline and Closure

In the early part of the 20th century, Kilbeggan, like many Irish whiskey distilleries at the time, entered a period of decline. This was due to the combined effects of loss and hampering of market access - due to prohibition in the United States, the trade war with the British Empire, shipping difficulties during the world wars, and Irish Government export quotas; as well as competition from blended Scotch, and disruption to production during the Irish war of Independence. As a result, Kilbeggan was forced to cease production of new spirit for 7 years between 1924 and 1931, decimating the company's cash flow and finances.Most of the staff at the distillery were let go, and the distillery slowly sold off its stocks of aged whiskey. Distilling resumed in 1931, following the end of prohibition in the United States, and for a time the distillery's finances improved - with a loss of £83 in 1931, converted to a modest profit of £6,700 in 1939. In the 1920s, both of John sons passed away, John in 1920, and James in 1927, and ownership of the distillery passed to Locke's granddaughters, Mary Evelyn and Florence Emily.However, by then the distillery was in need to repair, with the turbulent economic conditions of the early 20th century having meant that no investment had been made in new plant since the 1890s. In 1947, the Lockes decided to put the distillery was put up for sale as a going concern. Although run down, the distillery had valuable stocks of mature whiskey, a valuable commodity in post-war Europe.An offer of £305,000 was received from a Swiss investor fronted by an Englishman, going by the name of Horace Smith.Their unstated interest, was not the business itself, but the 60,000 gallons of whiskey stocks, which they hoped to sell on the black market in England at £11 a gallon - thus, more than doubling their investment overnight. However, when they failed to come up with the deposit, the duo were arrested and promptly interrogated by Irish police. The Englishman, it turned out, was an impostor named Maximoe, who was wanted by Scotland Yard.]The Irish authorities placed Maximoe on a ferry back to England for extradition, but he jumped overboard and escaped with the help of unknown accomplices. An Irish opposition politician, Oliver J. Flanagan, subsequently alleged under parliamentary privilege that members of the governing Fianna Fáil political party were linked to the deal, accusing then Irish Taoiseach Éamon de Valera and his son of having accepted gold watches from the Swiss businessman. A tribunal of inquiry discounted the allegations but the damage contributed to Fianna Fáil's defeat in the 1948 election. In addition, as the scandal remained headline news in Ireland for several months, it discouraged interest from other investors in the distillery. Thus with no buyer found, operations continued at the distillery, with production averaging between 120,000 - 150,000 proof gallons per annum, and consumption running at between 15,000 - 20,000 barrels of barrel.In addition, although heavily indebted, investments were made in new plant and equipment. However, the death knell for the distillery came in April 1952, when the Irish Government introduced a 28% hike in the excise duties on spirits, causing a drastic decline in domestic whiskey sales. By November 1953, the distillery could not afford to pay the duty to release whiskey ordered for Christmas from bond, and production was forced to come to a halt. Although distilling had stopped, the firm struggled on until 27 November 1958, when a debenture issued in 1953 fell due, which the distillery could not afford to pay, forcing the bank to call in the receivers. Thus, bringing to an end 201 years of distilling in the town. In 1962, the distillery was purchased for £10,000 by Karl Heinz Moller, a German businessman, who owned a motor distribution company in Hamburg.Moller made a substantial profit on the deal, by selling off the whiskey stocks (about 100,000 gallons - worth tens of thousands of pounds alone) and a rare Mercedes Benz owned by the distillery. Much to the dismay of locals, Moller proceeded to convert the distillery into a pigsty, smashing thousands of Locke earthenware crocks (which would be worth a substantial amount at auction today) to create a hard-core base for the concrete floor. In 1969, the distillery was sold to Powerscreen, a firm which sold Volvo loading shovels, and in the early 1970s, the stills and worms were removed and sold for scrap.Distillery reopens

In 1982, almost thirty years after the distillery ceased operations, the Kilbeggan Preservation and Development Association was formed by locals in the town. Using funds raised locally, the Association restored the Distillery, and reopened it to the public as a whiskey distillery museum. Then, in 1987, the newly opened Cooley Distillery acquired the assets of Kilbeggan distillery, allowing Cooley to relaunch whiskeys under the Kilbeggan and Locke's Whiskey brands. Cooley later also took over the running of the museum, and began the process of re-establishing a working distillery on-site. Cooley were aided in the process by the fact that since the distillery's closure, each subsequent owner had faithfully paid the £5 annual fee to maintain the distilling licence. In 2007, the 250th anniversary of the distillery's founding, distillation recommenced at Kilbeggan. The official firing of the pot stills was witnessed by direct descendants of the three families, the McManuses, the Codds, and the Lockes, who had run the distillery during its 200 year distilling history. In a fitting nod to the long history of distilling at Kilbeggan, one of the two pot stills installed in the refurbished distillery was a 180-year old pot still, which had originally been installed at the Old Tullamore Distillery in the early 1800s.] It is the oldest working pot still producing whiskey in the world today. In 2010, with the installation of a mash tun and fermentation vats, Kilbeggan became a fully operational distillery once again.Present day

Today the distillery is known as Kilbeggan Distillery, and includes a restaurant, The Pantry Restaurant, and a 19th-century waterwheel that has been restored to working condition. The distillery can also be powered by a steam engine, which is in working condition but rarely used. It was installed to allow the distillery to continue operating in times of low water on the river. Prior to the recommencement of operations of Kilbeggan, the three brands associated with the distillery—Kilbeggan, Locke's Blend and Locke's Malt were produced at the Cooley Distillery in County Louth, before being transported to Kilbeggan, where they were to stored in a 200 year old granite warehouse. However, following recommencement of operations at Kilbeggan, new whiskey produced on-site has been sufficiently mature for market since around 2014. Since reopening, the distillery has launched a Kilbeggan Small Batch Rye, the first whiskey to be 100% distilled and matured on-site since the restoration was completed. Double-distilled, the whiskey is produced from a mash of malt, barley, and about 30% rye, said to reflect the traditional practice of using rye, which was common at 19th century Irish distilleries, but has since virtually died out. In late 2009, the distillery released small '3-pack' samples of its still-developing "new make spirit" at 1 month, 1 year, and 2 years of age (in Ireland, the spirit must be aged a minimum of three years before it can legally be called "whiskey"). The distillery's visitor centre was among the nominations in Whisky Magazine's Icons of Whisky visitor attraction category in 2008.Gallery

-

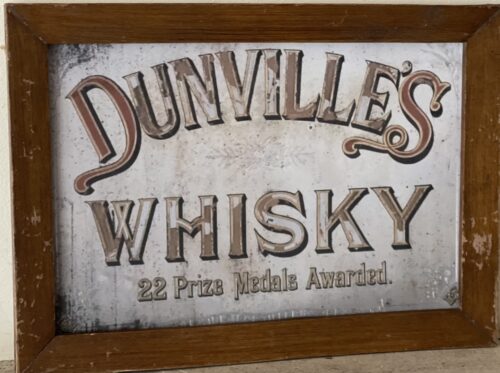

42cm x 30cm Dunville & Co Whisky Distillery was founded in Belfast Co Antrim in the 1820s,after initially gaining success as a whisky blender before constructing its own distillery.In 1837 Dunville began producing its most popular whiskey,Dunvilles VR.Athough Dunvilles was established and based in Ireland before partition and Irish Whiskey is normally spellt with an 'e',Dunvilles Whisky was always spelt without the vowel.This beautiful original print,originating from the Glens of Co Antrim,shows off the extent of the size of its Belfast distillery operation back in the day. Belfast 63cm x 80cm

42cm x 30cm Dunville & Co Whisky Distillery was founded in Belfast Co Antrim in the 1820s,after initially gaining success as a whisky blender before constructing its own distillery.In 1837 Dunville began producing its most popular whiskey,Dunvilles VR.Athough Dunvilles was established and based in Ireland before partition and Irish Whiskey is normally spellt with an 'e',Dunvilles Whisky was always spelt without the vowel.This beautiful original print,originating from the Glens of Co Antrim,shows off the extent of the size of its Belfast distillery operation back in the day. Belfast 63cm x 80cm -

Daly's Distillery was an Irish whiskey distillery which operated in Cork City, Ireland from around 1820 to 1869. In 1867, the distillery was purchased by the Cork Distilleries Company (CDC), in an amalgamation of five cork distilleries. Two years later, in 1869, as the smallest CDC distillery, Daly's Distillery ceased operations. In the years that followed its closure, some of the buildings became part of Shaw's Flour Mill, and Murphy's Brewery, with others continuing to be used as warehouses by Cork Distilleries Company for several years (though information is difficult to come by, their continued existence is mentioned in Alfred Barnard's 1887 account of the distilleries of the United Kingdom).

Daly's Distillery was an Irish whiskey distillery which operated in Cork City, Ireland from around 1820 to 1869. In 1867, the distillery was purchased by the Cork Distilleries Company (CDC), in an amalgamation of five cork distilleries. Two years later, in 1869, as the smallest CDC distillery, Daly's Distillery ceased operations. In the years that followed its closure, some of the buildings became part of Shaw's Flour Mill, and Murphy's Brewery, with others continuing to be used as warehouses by Cork Distilleries Company for several years (though information is difficult to come by, their continued existence is mentioned in Alfred Barnard's 1887 account of the distilleries of the United Kingdom).History

In 1798, the firm of James Daly & Co. was established as a rectifying distillery and wine merchants at a premises on Blarney St., Cork.In 1820, this was relocated to 32 John Street.As some sources state that the John distillery was established in 1807, and it is known that a William Lyons ran a distillery on John Street in the early 1800s, it is possible that Daly purchased an existing distillery on John Street. In 1822, James Daly's nephew John Murray joined the partnership.In 1828, the distillery is reported to have an output of 87,874 gallons of spirit.However, in 1833, output of only 39,000 gallons per annum was reported, which was low compared with some of the Irish distillers of the era; for instance, at that time Murphy's Distillery in nearby Midleton, had an output of over 400,000 gallons per annum. On James Daly's death, in 1850, the partnership, which at that point had consisted of James Daly, Maurice Murray (John Murray's son) and George Waters, was dissolved, with Maurice Murray taking sole ownership of the distillery, which continued to trade as James Daly & Co. After leaving the partnership, George Waters went on to purchase and run the nearby Green distillery. In 1853, Murray rebuilt and significantly extended the distillery, expanding onto neighbouring streets. By the late 1860s, the distillery had grown to occupy 3 acres, consisting of a brewhouse, distillery and maltings on John Street; granaries on Leitrim Street; and eight bonded warehouses scattered across John Street, Leitrim Street and Watercourse Road.According to accounts from the time, whiskey from the distillery, some of which was aged for seven years or more, was mainly exported "to the colonies". In particular, it was said that in Australia the whiskey sold at a premium to other whiskeys. A well respected member of the Irish distilling industry at the time, the distillery's owner Maurice Murray, conducted significant correspondence with William Ewart Gladstone, the then British Chancellor of the Exchequer, on behalf of the Irish distillers, with regard to the duties placed on Irish whiskey. In 1867, Daly's Distillery, was absorbed into Cork Distilleries Company (CDC), in an amalgamation of five Cork distilleries.As the smallest of the five distilleries, Daly's closed soon after the amalgamation, in 1869. Following its closure, Maurice Murray is known to have continued to work for the CDC at the North Mall Distillery, along with his son Daly Murray. The main distillery buildings later became part of Shaw's Flour Mill, while other buildings were incorporated into the nearby Murphy's Brewery, which was run by relatives of James Murphy of the Midleton Distillery, who was the driving force behind the establishment of the Cork Distilleries Company. One of the distillery buildings, now named "the Mill", is still visible on 32 Lower John Street, Cork. -

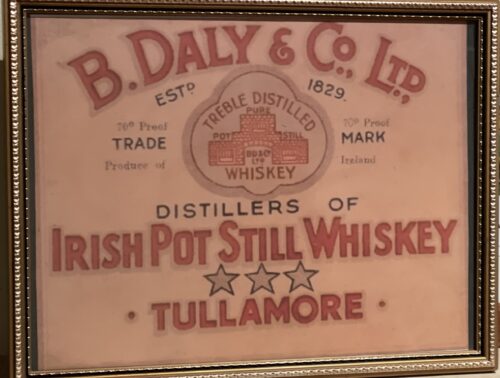

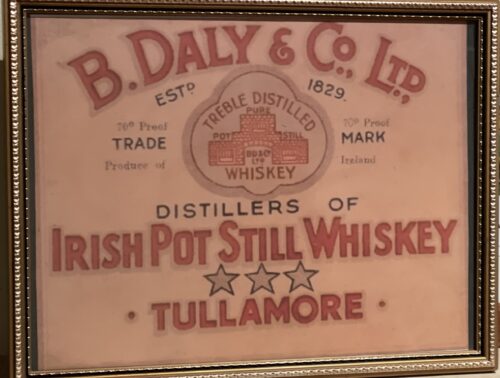

45cm x 34cmThe Tullamore Distillery was founded in 1829 by Michael Molloy, in Tullamore, County Offaly, Ireland. When Molloy dead, in 1846, the distillery passed into the hands of one of his five nephews, Bernard Daly, and under the general management of Daniel E. Williams. 40 years later, in 1887, Bernard Daly died, and Tullamore Distillery passed to his son Captain Bernard Daly, who left, as always, the running of the distillery to Daniel E. Williams. Under Daniel E. Williams, the Tullamore Distillery expanded and prospered, lunching the whiskey which still bears his initials, Tullamore D.E.W. Williams was very resourceful and brought electricity to Tullamore in 1893. He installed telephones and motorised automobiles in the distillery. In 1903, the distillery was incorporated into a company under the name B Daly & Co. Ltd., of which both Daly and Williams had shares. The Tullamore Distillery, finally, came under complete control of Williams family in 1931. From 1925 to 1937, due to the advent of competition and to cut costs, Tullamore Distillery was temporarily mothballed. In the 1940s, Desmond, the grandson of Daniel E. Williams, began into alternative products, and with whiskey sales still languishing, the company decided to focus its resources on the liqueur Irish Mist. Therefore, distilling operations ceased in Tullamore in 1954, and production was temporarily moved to Power's Distillery in Dublin, and was later moved to Midleton Distillery and Bushmill's Distillery. William Grant & Sons acquired Tullamore brand in 2010 and, in March 2012, they announced that they were in the final stages of negotiations to acquire a site at Clonminch, situated on the outskirts of Tullamore. Construction of a new distillery began in May 2013 and in autumn 2014, the distillery was ready to start production in its ancestral home of Tullamore. The construction will be executed in three phases where the first was a pot still distillery with the possibility to distil 1,8 million litres per year. In early 2016, it was increased to 3,6 million litres by the addition of more stills and washbacks. Finally, a grain distillery and bottling plant were added in 2017. Tullamore can now produce all three components of its Tullamore D.E.W. blended whiskey on-site.

45cm x 34cmThe Tullamore Distillery was founded in 1829 by Michael Molloy, in Tullamore, County Offaly, Ireland. When Molloy dead, in 1846, the distillery passed into the hands of one of his five nephews, Bernard Daly, and under the general management of Daniel E. Williams. 40 years later, in 1887, Bernard Daly died, and Tullamore Distillery passed to his son Captain Bernard Daly, who left, as always, the running of the distillery to Daniel E. Williams. Under Daniel E. Williams, the Tullamore Distillery expanded and prospered, lunching the whiskey which still bears his initials, Tullamore D.E.W. Williams was very resourceful and brought electricity to Tullamore in 1893. He installed telephones and motorised automobiles in the distillery. In 1903, the distillery was incorporated into a company under the name B Daly & Co. Ltd., of which both Daly and Williams had shares. The Tullamore Distillery, finally, came under complete control of Williams family in 1931. From 1925 to 1937, due to the advent of competition and to cut costs, Tullamore Distillery was temporarily mothballed. In the 1940s, Desmond, the grandson of Daniel E. Williams, began into alternative products, and with whiskey sales still languishing, the company decided to focus its resources on the liqueur Irish Mist. Therefore, distilling operations ceased in Tullamore in 1954, and production was temporarily moved to Power's Distillery in Dublin, and was later moved to Midleton Distillery and Bushmill's Distillery. William Grant & Sons acquired Tullamore brand in 2010 and, in March 2012, they announced that they were in the final stages of negotiations to acquire a site at Clonminch, situated on the outskirts of Tullamore. Construction of a new distillery began in May 2013 and in autumn 2014, the distillery was ready to start production in its ancestral home of Tullamore. The construction will be executed in three phases where the first was a pot still distillery with the possibility to distil 1,8 million litres per year. In early 2016, it was increased to 3,6 million litres by the addition of more stills and washbacks. Finally, a grain distillery and bottling plant were added in 2017. Tullamore can now produce all three components of its Tullamore D.E.W. blended whiskey on-site.- 1829 Tullamore Distillery was founded by Michael Molloy, in Tullamore, County Offaly, Ireland

- 1846 Molloy dead and the distillery passed into the hands of one of his five nephews, Bernard Daly

- 1887 Bernard Daly dead and Tullamore Distillery passed to his son Captain B. Daly

- 1893 Williams brought electricity to Tullamore

- 1903 The distillery was incorporate under tha name B Daly & Co. Ltd.

- 1925-1937 Tullamore Distillery was temporarily closed

- 1931 Tullamore came under complete control of Williams family

- 1954 The old Tullamore Distillery closed and production was transferred to the Midleton Distillery

- 2010 The brand was purchased by William Grant & Sons, who invested €35 million in the construction of the new Tullamore Distillery

- 2014 The new Tullamore Distillery opened

-

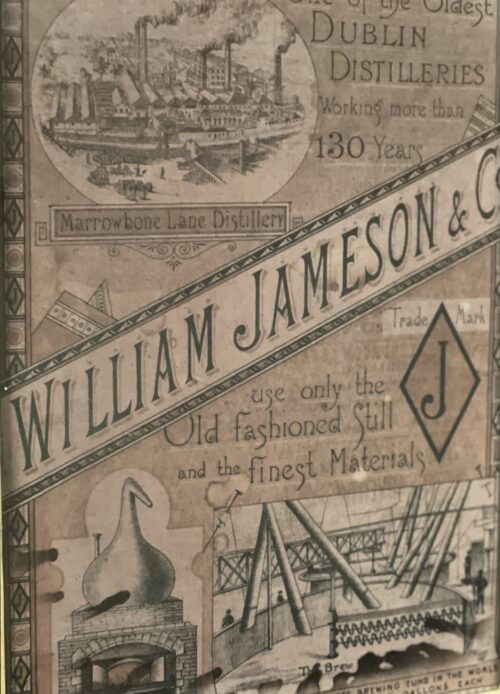

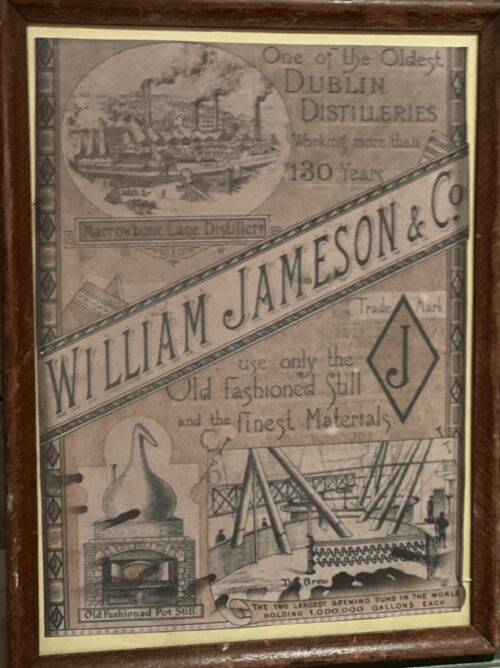

44cm x 34cm Dublin The Marrowbone Lane Distillery was an Irish whiskey distillery located on Marrowbone Lane, in Dublin, Ireland. One of the "big four" historical Dublin whiskey firms, it was run by William Jameson, a member of the Jameson whiskey dynasty. However, the whiskey now known as Jameson Irish Whiskey was not produced at this distillery, but at the separate enterprise run by John Jameson at the nearby Bow Street Distillery. The distillery closed in 1923 following financial difficulties.The precise origins of the distillery are uncertain, however, it was likely established in the 1750s (possibly 1752) and later acquired by the Stein family, relatives of the Jameson family circa 1780. An excise return in 1802 lists Stein and Jameson, however, by 1822 the company had become William Jameson & Co. Initially a small undertaking, with an output of just 30,000 gallons per annum, the distillery expanded over time, and by the time Alfred Barnard, a British historian visited the distillery in the 1880s, it had grown to cover some 14 acres. In his book, The Whisky Distilleries of the United Kingdom, Barnard described Marrowbone Lane as having some of the biggest distilling equipment in the world, including two mash tuns with capacities in excess of 100,000 gallons, which were the "said to be the largest in the United Kingdom". At its peak, the distillery was the second largest in Dublin (then one of the world's largest whiskey distilling centres), with an output of 900,000 gallons per annum, and a staff of 200, including 30 coopers. The whiskey produced at the distillery, known as "Dublin Whiskey" was chiefly exported to Australia, Canada, India and the United States. Later renamed the Dublin Distilling Company, the company entered financial difficulties in the late 1800s, and in 1891, merged with George Roe's Thomas Street Distillery and the Dublin Whiskey Distillery Company's Jones Road Distillery to form the Dublin Distilleries Company Ltd. Although, the amalgamated company had a potential production capacity of 3.5 million gallons per annum, it continued to endure severe financial difficulties, in particular, following the loss of both the American and British Commonwealth export markets during prohibition and the Anglo-Irish trade war in the 1920s. Both the Thomas Street and Marrowbone Lane distilleries closed in 1923, with the Jones Road Distillery following suit in 1926. Though distilling may have continued at Jones Road until 1946. During the 1916 Easter uprising, both the Marrowbone Lane distillery and Roe's distillery at Thomas Street were used as strongpoints by a force of more than a hundred rebels.