30cm x 30cm

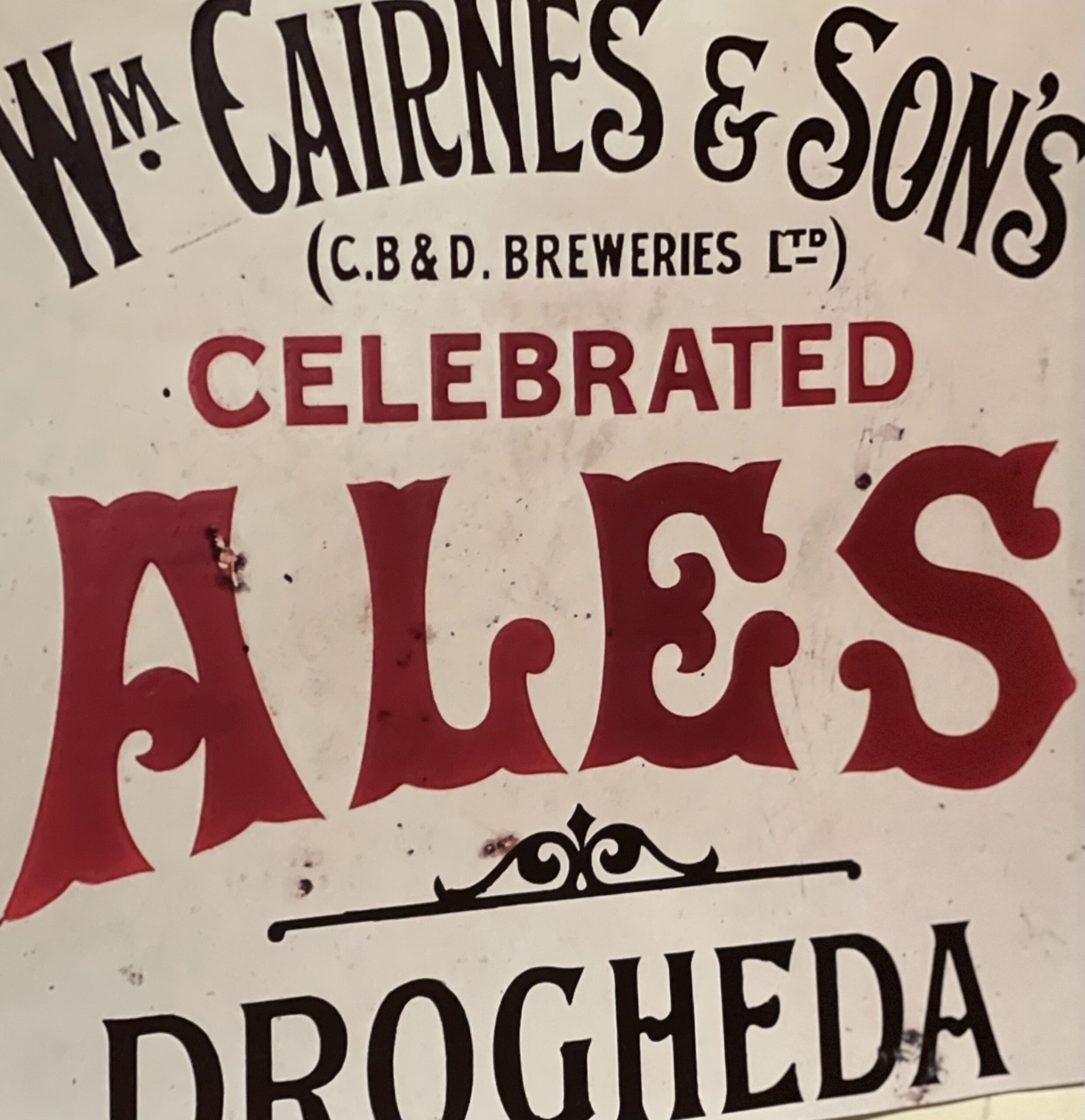

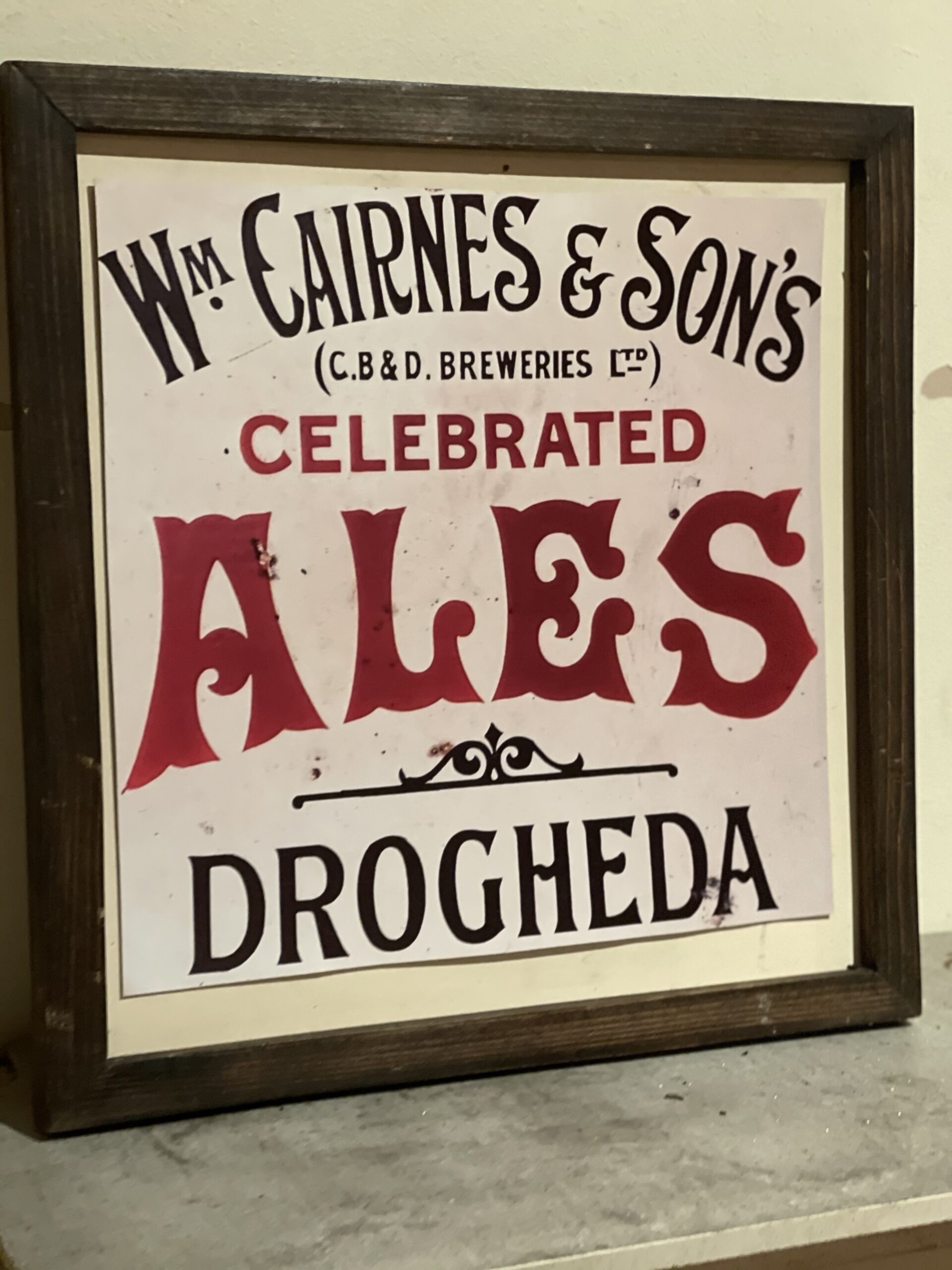

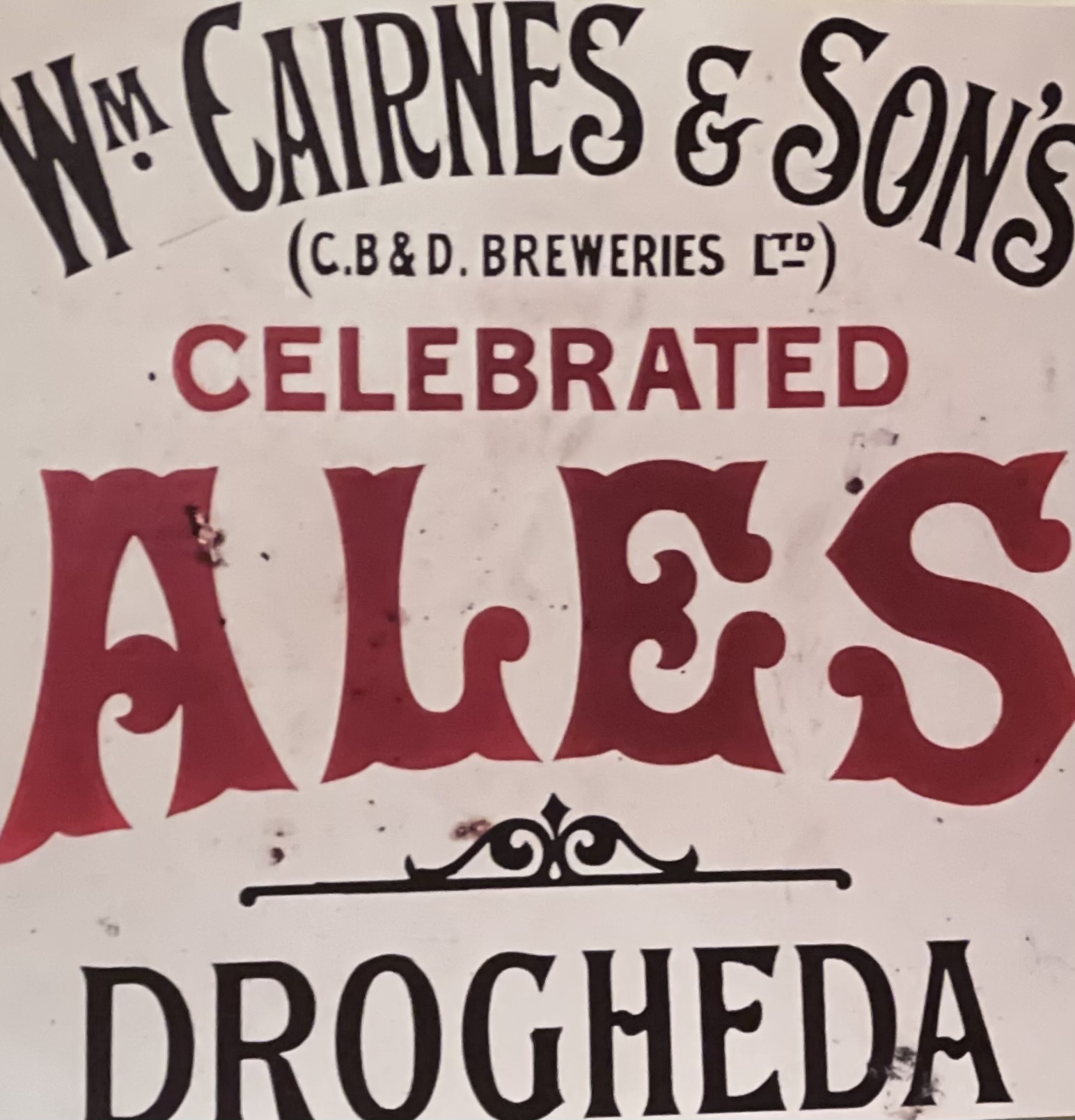

ANOTHER great industry on the Scotch Hall site was the brewing firm of Cairnes Ltd, one of the original firms of Irish brewers dating back to 1772 with the foundation of the Castlebellingham Brewery at the picturesque Co Louth village of that name.In 1825, William Cairnes, who was related by marriage to the owners of the ’Bellingham brewery, founded the brewery at Marsh Road, Drogheda, which, for over 150 years, gave employment to almost 200 workers and the firm was famous for its ales and stout.

In 1889 the interests of the two breweries were pooled, a public company being formed under the title of the Castlebellingham and Drogheda Breweries Ltd. This title was changed for brevity in 1933 to Cairnes Ltd.

For a good many years subsequent to the merger, the breweries were worked independently, each supplying its own customers throughout Ireland and abroad.

However, in 1923, it was considered advisable to concentrate brewing in Drogheda, owing to the more advantageous position of the town, and the brewing plant and premises there, were more extensive.

Actually the plant at Drogheda was one of the most up-to-date in Ireland and compared very favourably with that of breweries in England and Wales. The supply of brewing water was obtained from a 400ft deep artesian well on the company’s premises. (I wonder if it is still there) and this water was used with the choicest hops and malt made from the best Irish barley obtainable. The hops used came chiefly from Kent and when obtainable, a percentage came from the USA.

The process through which the barley went from its arrival in the brewery until it emerged as ale or stout, was extremely interesting and quaint. The barley was first dried to a consistent level of moisture content and then stored for a few weeks before being steeped.

It was then ‘floored’ on lots which the brewery had, as well as lofts in Dominic Street and Wellington Quay.

These have, in recent years, been converted into shops and a high rise apartment block. Here on these lofts the growing process of the barley in the ground was artificially repeated, the growth however being terminated at the desired stage. The barley was then kilned and cured before being ground and mashed with hot water and the liquid was drawn off. It was then run to built-in coppers, where hops was added, then boiled, the wort, as it was called, being subsequently strained from the hops, cooled and fermented. The final stage was when the beer was casked (in wooden barrels) and matured.