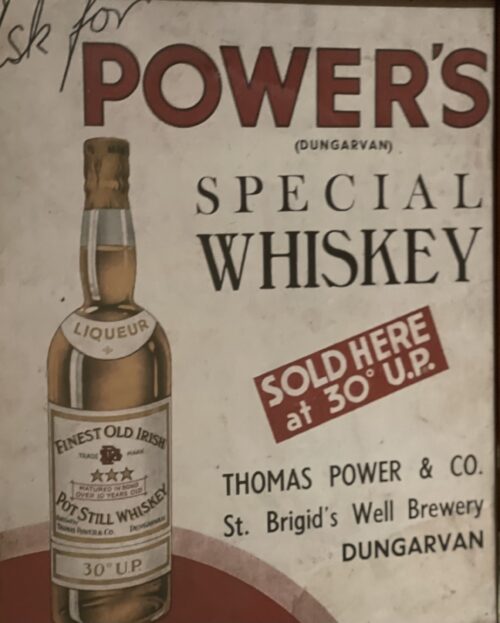

Thomas Power (1856-1930) was the first chairman of Waterford County Council and was chairman of Dungarvan Town Commissioners on a number of occasions. In the 1880s he was in partnership with his brother producing mineral waters. In 1904 he began producing his award winning Blackwater Cider.

In 1917 Thomas purchased the old St Brigid's Well Brewery in Fair Lane, Dungarvan from the Marquis of Waterford. The business was a great success and its produce was in demand all over County Waterford and beyond. After his death the brewery was taken over by his son Paul I. Power who managed it until 1976 when his son Ion took over.

Brewing took place in Dungarvan throughout history but we only have detailed information from the late 18th century onwards. In 1917 the Marquis sold the property and it was acquired by Thomas Power. He developed a thriving business known as Power's Brewery. This brewing tradition continues into the modern era with the Dungarvan Brewing Company.

-

47cm x 37cm Limerick Here’s a quick, but loaded, question: Do you prefer Barry’s or Lyons? The Great Irish Tea War is the most intractable rivalry in the country. While Munster and Leinster have been known to put their differences aside for the sake of Irish rugby glory, tea drinkers are not so easily appeased. Mention a preference for the “wrong” tea and you can expect strong words at best – and definitely no biscuits. At worst, tea drinkers will go cup to cup in pitched battles, kettles angrily steaming, while insults like curdled milk sour friendships and family relationships. It’s more than just a battle of the brews. Barry’s Tea was founded the Rebel City in 1901 and is still one of Cork’s most famous brands. Lyons is originally from Dublin. Do you prefer Barry’s to Lyons? The yellow Snack or the purple one? Tayto or King Crisps? Cork or Dublin? Really, it is all a matter of taste… But there are many great reasons why anyone looking for a new job, or a whole new life, should consider a move to Cork.Lyons is a brand of tea belonging to Unilever that is sold in Ireland. It is one of the two dominant tea brands in the market within the Republic of Ireland, along with Barry's Tea. Lyons Tea was first produced by J. Lyons and Co., a catering empire created and built by the Salmons and Glucksteins, a German-Jewish immigrant family based in London. Starting in 1904, J Lyons began selling packaged tea through its network of teashops. Soon after, they began selling their own brand Lyons Tea through retailers in the UK, Ireland and around the world.In 1918, Lyons purchased Hornimans and in 1921 they moved their tea factory to J. Lyons and Co., Greenford at that time, the largest tea factory in Europe. In 1962, J Lyons and Company (Ireland) became Lyons Irish Holdings. After a merger with Allied Breweries in 1978, Lyons Irish Holdings became part of Allied Lyons (later Allied Domecq) who then sold the company to Unilever in 1996. Today, Lyons Tea is produced in England. Lyons Tea was a major advertiser in the early decades of RTÉ Television, featuring the "Lyons minstrels" and coupon-based prize competitions. The story of J Lyons is told in the book 'Legacy: One Family, a Cup of Tea and the Company that Took On the World' by Thomas Harding (writer)

47cm x 37cm Limerick Here’s a quick, but loaded, question: Do you prefer Barry’s or Lyons? The Great Irish Tea War is the most intractable rivalry in the country. While Munster and Leinster have been known to put their differences aside for the sake of Irish rugby glory, tea drinkers are not so easily appeased. Mention a preference for the “wrong” tea and you can expect strong words at best – and definitely no biscuits. At worst, tea drinkers will go cup to cup in pitched battles, kettles angrily steaming, while insults like curdled milk sour friendships and family relationships. It’s more than just a battle of the brews. Barry’s Tea was founded the Rebel City in 1901 and is still one of Cork’s most famous brands. Lyons is originally from Dublin. Do you prefer Barry’s to Lyons? The yellow Snack or the purple one? Tayto or King Crisps? Cork or Dublin? Really, it is all a matter of taste… But there are many great reasons why anyone looking for a new job, or a whole new life, should consider a move to Cork.Lyons is a brand of tea belonging to Unilever that is sold in Ireland. It is one of the two dominant tea brands in the market within the Republic of Ireland, along with Barry's Tea. Lyons Tea was first produced by J. Lyons and Co., a catering empire created and built by the Salmons and Glucksteins, a German-Jewish immigrant family based in London. Starting in 1904, J Lyons began selling packaged tea through its network of teashops. Soon after, they began selling their own brand Lyons Tea through retailers in the UK, Ireland and around the world.In 1918, Lyons purchased Hornimans and in 1921 they moved their tea factory to J. Lyons and Co., Greenford at that time, the largest tea factory in Europe. In 1962, J Lyons and Company (Ireland) became Lyons Irish Holdings. After a merger with Allied Breweries in 1978, Lyons Irish Holdings became part of Allied Lyons (later Allied Domecq) who then sold the company to Unilever in 1996. Today, Lyons Tea is produced in England. Lyons Tea was a major advertiser in the early decades of RTÉ Television, featuring the "Lyons minstrels" and coupon-based prize competitions. The story of J Lyons is told in the book 'Legacy: One Family, a Cup of Tea and the Company that Took On the World' by Thomas Harding (writer)Popular culture

A Lyons Tea sign is shown in the background in a scene in Castletown in The Quiet Man (1952), the iconic film directed by John Ford that starred John Wayne and Maureen O'Hara. Again in Ford’s ‘’How Green Was My Valley’’ (1941) an advertisement for Lyon’s Tea is to be seen in an early scene under the shop window near the church. In the BBC/RTÉ Mrs Brown's Boys TV series, there is a box of Lyons Tea sitting on top of the bread bin in Mrs Brown's kitchen. In Chariots of Fire, a Lyons sign is shown at Dover train station. -

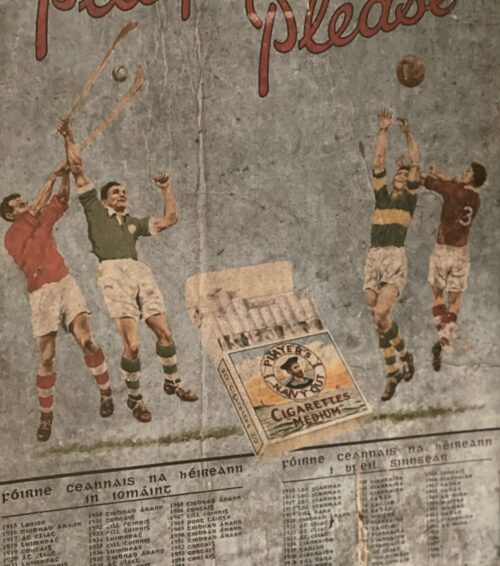

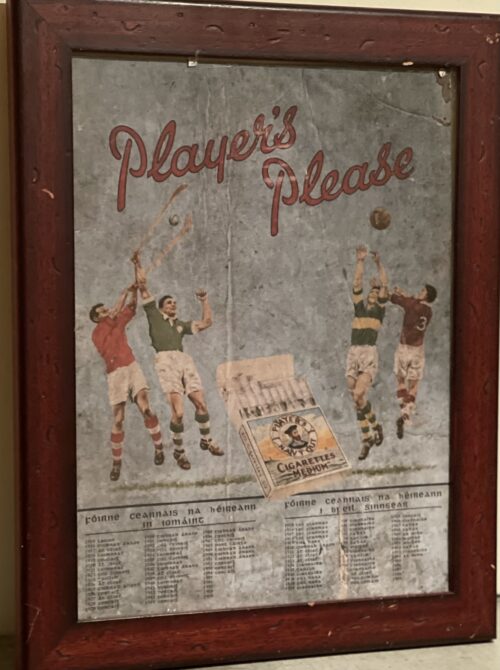

47cm x 37cm Limerick Navy cut were a brand of cigarettes manufactured by Imperial Brands –formerly John Player & Sons– in Nottingham, England.The brand became "Player's Navy Cut". They were particularly popular in Britain,Ireland and Germany in the late 19th century and early part of the 20th century, but were later produced in the United States. The packet has the distinctive logo of a smoking sailor in a 'Navy Cut' cap. The phrase "Navy Cut" is according to Player's adverts to originate from the habit of sailors taking a mixture of tobacco leaves and binding them with string or twine. The tobacco would then mature under pressure and the sailor could then dispense the tobacco by slicing off a "cut".The product is also available in pipe tobacco form. The cigarettes were available in tins and the original cardboard container was a four sided tray of cigarettes that slid out from a covering like a classic matchbox. The next design had fold in ends so that the cigarettes could be seen or dispensed without sliding out the tray. In the 1950s the packaging moved to the flip top design like most brands. The image of the sailor was known as "Hero" because of the name on his hat band. It was first used in 1883 and the lifebuoy was added five years later. The sailor images were an 1891 artists concept registered for Chester-based William Parkins and Co for their "Jack Glory" brand.Behind the sailor are two ships. The one on the left is thought to be HMS Britannia and the one on the right HMS Dreadnought or HMS Hero. As time went by the image of the sailor changed as it sometimes had a beard and other times he was clean shaven. In 1927 "Hero" was standardised on a 1905 version. As part of the 1927 marketing campaign John Player and Sons commissioned an oil painting Head of a Sailor by Arthur David McCormick.The Player's Hero logo was thought to contribute to the cigarettes popularity in the 20s and 30s when competitor W.D. & H.O. Wills tried to create a similar image. Unlike Craven A, Navy Cut was intended to have a unisex appeal. Advertisements referred to "the appeal to Eve's fair daughters" and lines like "Men may come and Men may go".Hero is thought to have originally meant to indicate traditional British values, but his masculinity appealed directly to men and as a potential uncle figure for younger women. One slogan written inside the packet was "It's the tobacco that counts" and another was "Player's Please" which was said to appeal to the perceived desire of the population to be included in the mass market. The slogan was so well known that it was sufficient in a shop to get a packet of this brand. Player's Medium Navy Cut was the most popular by far of the three Navy Cut brands (there was also Mild and Gold Leaf). Two thirds of all the cigarettes sold in Britain were Players and two thirds of these was branded as Players Medium Navy Cut. In January 1937, Players sold nearly 3.5 million cigarettes (which included 1.34 million in London. The popularity of the brand was mostly amongst the middle class and in the South of England. While it was smoked in the north, other brands were locally more popular. The brand was discontinued in the UK in 2016.WWII cigarette packets exhibited at Monmouth Regimental Museumin 2012

47cm x 37cm Limerick Navy cut were a brand of cigarettes manufactured by Imperial Brands –formerly John Player & Sons– in Nottingham, England.The brand became "Player's Navy Cut". They were particularly popular in Britain,Ireland and Germany in the late 19th century and early part of the 20th century, but were later produced in the United States. The packet has the distinctive logo of a smoking sailor in a 'Navy Cut' cap. The phrase "Navy Cut" is according to Player's adverts to originate from the habit of sailors taking a mixture of tobacco leaves and binding them with string or twine. The tobacco would then mature under pressure and the sailor could then dispense the tobacco by slicing off a "cut".The product is also available in pipe tobacco form. The cigarettes were available in tins and the original cardboard container was a four sided tray of cigarettes that slid out from a covering like a classic matchbox. The next design had fold in ends so that the cigarettes could be seen or dispensed without sliding out the tray. In the 1950s the packaging moved to the flip top design like most brands. The image of the sailor was known as "Hero" because of the name on his hat band. It was first used in 1883 and the lifebuoy was added five years later. The sailor images were an 1891 artists concept registered for Chester-based William Parkins and Co for their "Jack Glory" brand.Behind the sailor are two ships. The one on the left is thought to be HMS Britannia and the one on the right HMS Dreadnought or HMS Hero. As time went by the image of the sailor changed as it sometimes had a beard and other times he was clean shaven. In 1927 "Hero" was standardised on a 1905 version. As part of the 1927 marketing campaign John Player and Sons commissioned an oil painting Head of a Sailor by Arthur David McCormick.The Player's Hero logo was thought to contribute to the cigarettes popularity in the 20s and 30s when competitor W.D. & H.O. Wills tried to create a similar image. Unlike Craven A, Navy Cut was intended to have a unisex appeal. Advertisements referred to "the appeal to Eve's fair daughters" and lines like "Men may come and Men may go".Hero is thought to have originally meant to indicate traditional British values, but his masculinity appealed directly to men and as a potential uncle figure for younger women. One slogan written inside the packet was "It's the tobacco that counts" and another was "Player's Please" which was said to appeal to the perceived desire of the population to be included in the mass market. The slogan was so well known that it was sufficient in a shop to get a packet of this brand. Player's Medium Navy Cut was the most popular by far of the three Navy Cut brands (there was also Mild and Gold Leaf). Two thirds of all the cigarettes sold in Britain were Players and two thirds of these was branded as Players Medium Navy Cut. In January 1937, Players sold nearly 3.5 million cigarettes (which included 1.34 million in London. The popularity of the brand was mostly amongst the middle class and in the South of England. While it was smoked in the north, other brands were locally more popular. The brand was discontinued in the UK in 2016.WWII cigarette packets exhibited at Monmouth Regimental Museumin 2012 -

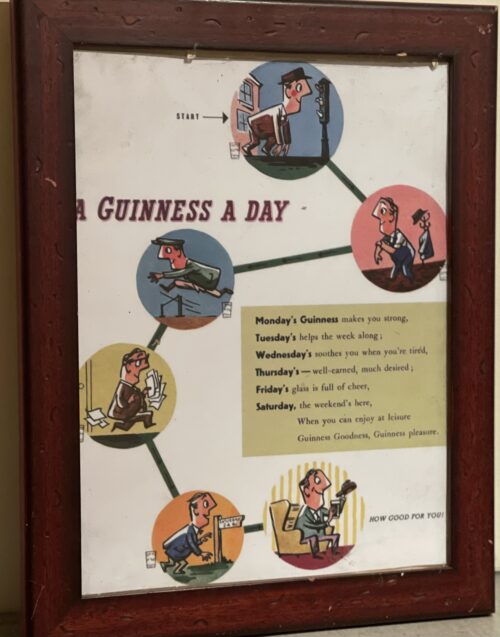

47cm x 37cm Limerick Arthur Guinness started brewing ales in 1759 at the St James Gate Brewery,Dublin.On 31st December 1759 he signed a 9,000 year lease at £45 per annum for the unused brewery.Ten years later, on 19 May 1769, Guinness first exported his ale: he shipped six-and-a-half barrels to Great Britain before he started selling the dark beer porter in 1778. The first Guinness beers to use the term were Single Stout and Double Stout in the 1840s.Throughout the bulk of its history, Guinness produced only three variations of a single beer type: porter or single stout, double or extra and foreign stout for export. “Stout” originally referred to a beer’s strength, but eventually shifted meaning toward body and colour.Porter was also referred to as “plain”, as mentioned in the famous refrain of Flann O’Brien‘s poem “The Workman’s Friend”: “A pint of plain is your only man.” Already one of the top-three British and Irish brewers, Guinness’s sales soared from 350,000 barrels in 1868 to 779,000 barrels in 1876.In October 1886 Guinness became a public company, and was averaging sales of 1,138,000 barrels a year. This was despite the brewery’s refusal to either advertise or offer its beer at a discount. Even though Guinness owned no public houses, the company was valued at £6 million and shares were twenty times oversubscribed, with share prices rising to a 60 per cent premium on the first day of trading. The breweries pioneered several quality control efforts. The brewery hired the statistician William Sealy Gosset in 1899, who achieved lasting fame under the pseudonym “Student” for techniques developed for Guinness, particularly Student’s t-distribution and the even more commonly known Student’s t-test. By 1900 the brewery was operating unparalleled welfare schemes for its 5,000 employees. By 1907 the welfare schemes were costing the brewery £40,000 a year, which was one-fifth of the total wages bill. The improvements were suggested and supervised by Sir John Lumsden. By 1914, Guinness was producing 2,652,000 barrels of beer a year, which was more than double that of its nearest competitor Bass, and was supplying more than 10 per cent of the total UK beer market. In the 1930s, Guinness became the seventh largest company in the world. Before 1939, if a Guinness brewer wished to marry a Catholic, his resignation was requested. According to Thomas Molloy, writing in the Irish Independent, “It had no qualms about selling drink to Catholics but it did everything it could to avoid employing them until the 1960s.” Guinness thought they brewed their last porter in 1973. In the 1970s, following declining sales, the decision was taken to make Guinness Extra Stout more “drinkable”. The gravity was subsequently reduced, and the brand was relaunched in 1981. Pale malt was used for the first time, and isomerized hop extract began to be used. In 2014, two new porters were introduced: West Indies Porter and Dublin Porter. Guinness acquired the Distillers Company in 1986.This led to a scandal and criminal trialconcerning the artificial inflation of the Guinness share price during the takeover bid engineered by the chairman, Ernest Saunders. A subsequent £5.2 million success fee paid to an American lawyer and Guinness director, Tom Ward, was the subject of the case Guinness plc v Saunders, in which the House of Lords declared that the payment had been invalid. In the 1980s, as the IRA’s bombing campaign spread to London and the rest of Britain, Guinness considered scrapping the Harp as its logo. The company merged with Grand Metropolitan in 1997 to form Diageo. Due to controversy over the merger, the company was maintained as a separate entity within Diageo and has retained the rights to the product and all associated trademarks of Guinness.The Guinness brewery in Park Royal, London closed in 2005. The production of all Guinness sold in the UK and Ireland was moved to St. James’s Gate Brewery, Dublin. Guinness has also been referred to as “that black stuff”. Guinness had a fleet of ships, barges and yachts. The Irish Sunday Independent newspaper reported on 17 June 2007 that Diageo intended to close the historic St James’s Gate plant in Dublin and move to a greenfield site on the outskirts of the city.This news caused some controversy when it was announced.The following day, the Irish Daily Mail ran a follow-up story with a double page spread complete with images and a history of the plant since 1759. Initially, Diageo said that talk of a move was pure speculation but in the face of mounting speculation in the wake of the Sunday Independent article, the company confirmed that it is undertaking a “significant review of its operations”. This review was largely due to the efforts of the company’s ongoing drive to reduce the environmental impact of brewing at the St James’s Gate plant. On 23 November 2007, an article appeared in the Evening Herald, a Dublin newspaper, stating that the Dublin City Council, in the best interests of the city of Dublin, had put forward a motion to prevent planning permission ever being granted for development of the site, thus making it very difficult for Diageo to sell off the site for residential development. On 9 May 2008, Diageo announced that the St James’s Gate brewery will remain open and undergo renovations, but that breweries in Kilkenny and Dundalk will be closed by 2013 when a new larger brewery is opened near Dublin. The result will be a loss of roughly 250 jobs across the entire Diageo/Guinness workforce in Ireland.Two days later, the Sunday Independent again reported that Diageo chiefs had met with Tánaiste Mary Coughlan, the deputy leader of the Government of Ireland, about moving operations to Ireland from the UK to benefit from its lower corporation tax rates. Several UK firms have made the move in order to pay Ireland’s 12.5 per cent rate rather than the UK’s 28 per cent rate. Diageo released a statement to the London stock exchange denying the report.Despite the merger that created Diageo plc in 1997, Guinness has retained its right to the Guinness brand and associated trademarks and thus continues to trade under the traditional Guinness name despite trading under the corporation name Diageo for a brief period in 1997. In November 2015 it was announced that Guinness are planning to make their beer suitable for consumption by vegetarians and vegans by the end of 2016 through the introduction of a new filtration process at their existing Guinness Brewery that avoids the need to use isinglass from fish bladders to filter out yeast particles.This went into effect in 2017, per the company’s FAQ webpage where they state: “Our new filtration process has removed the use of isinglass as a means of filtration and vegans can now enjoy a pint of Guinness. All Guinness Draught in keg format is brewed without using isinglass. Full distribution of bottle and can formats will be in place by the end of 2017, so until then, our advice to vegans is to consume the product from the keg format only for now. Guinness stout is made from water, barley, roast malt extract, hops, and brewer’s yeast. A portion of the barley is roasted to give Guinness its dark colour and characteristic taste. It is pasteurisedand filtered. Until the late 1950s Guinness was still racked into wooden casks. In the late 1950s and early 1960s, Guinness ceased brewing cask-conditioned beers and developed a keg brewing system with aluminium kegs replacing the wooden casks; these were nicknamed “iron lungs”.Until 2016 the production of Guinness, as with many beers, involved the use of isinglass made from fish. Isinglass was used as a fining agent for settling out suspended matter in the vat. The isinglass was retained in the floor of the vat but it was possible that minute quantities might be carried over into the beer. Diageo announced in February 2018 that the use of isinglass in draught Guinness was to be discontinued and an alternative clarification agent would be used instead. This has made draught Guinness acceptable to vegans and vegetarians. Arguably its biggest change to date, in 1959 Guinness began using nitrogen, which changed the fundamental texture and flavour of the Guinness of the past as nitrogen bubbles are much smaller than CO2, giving a “creamier” and “smoother” consistency over a sharper and traditional CO2 taste. This step was taken after Michael Ash – a mathematician turned brewer – discovered the mechanism to make this possible. Nitrogen is less soluble than carbon dioxide, which allows the beer to be put under high pressure without making it fizzy. High pressure of the dissolved gas is required to enable very small bubbles to be formed by forcing the draught beer through fine holes in a plate in the tap, which causes the characteristic “surge” (the widget in cans and bottles achieves the same effect). This “widget” is a small plastic ball containing the nitrogen. The perceived smoothness of draught Guinness is due to its low level of carbon dioxide and the creaminess of the head caused by the very fine bubbles that arise from the use of nitrogen and the dispensing method described above. “Foreign Extra Stout” contains more carbon dioxide, causing a more acidic taste. Contemporary Guinness Draught and Extra Stout are weaker than they were in the 19th century, when they had an original gravity of over 1.070. Foreign Extra Stout and Special Export Stout, with abv of 7.5% and 9% respectively, are perhaps closest to the original in character.Although Guinness may appear to be black, it is officially a very dark shade of ruby. The most recent change in alcohol content from the Import Stout to the Extra Stout was due to a change in distribution through North American market. Consumer complaints have influenced recent distribution and bottle changes. Studies claim that Guinness can be beneficial to the heart. Researchers found that “‘antioxidantcompounds’ in the Guinness, similar to those found in certain fruits and vegetables, are responsible for the health benefits because they slow down the deposit of harmful cholesterol on the artery walls.”Guinness ran an advertising campaign in the 1920s which stemmed from market research – when people told the company that they felt good after their pint, the slogan, created by Dorothy L. Sayers–”Guinness is Good for You”. Advertising for alcoholic drinks that implies improved physical performance or enhanced personal qualities is now prohibited in Ireland.Diageo, the company that now manufactures Guinness, says: “We never make any medical claims for our drinks.”

47cm x 37cm Limerick Arthur Guinness started brewing ales in 1759 at the St James Gate Brewery,Dublin.On 31st December 1759 he signed a 9,000 year lease at £45 per annum for the unused brewery.Ten years later, on 19 May 1769, Guinness first exported his ale: he shipped six-and-a-half barrels to Great Britain before he started selling the dark beer porter in 1778. The first Guinness beers to use the term were Single Stout and Double Stout in the 1840s.Throughout the bulk of its history, Guinness produced only three variations of a single beer type: porter or single stout, double or extra and foreign stout for export. “Stout” originally referred to a beer’s strength, but eventually shifted meaning toward body and colour.Porter was also referred to as “plain”, as mentioned in the famous refrain of Flann O’Brien‘s poem “The Workman’s Friend”: “A pint of plain is your only man.” Already one of the top-three British and Irish brewers, Guinness’s sales soared from 350,000 barrels in 1868 to 779,000 barrels in 1876.In October 1886 Guinness became a public company, and was averaging sales of 1,138,000 barrels a year. This was despite the brewery’s refusal to either advertise or offer its beer at a discount. Even though Guinness owned no public houses, the company was valued at £6 million and shares were twenty times oversubscribed, with share prices rising to a 60 per cent premium on the first day of trading. The breweries pioneered several quality control efforts. The brewery hired the statistician William Sealy Gosset in 1899, who achieved lasting fame under the pseudonym “Student” for techniques developed for Guinness, particularly Student’s t-distribution and the even more commonly known Student’s t-test. By 1900 the brewery was operating unparalleled welfare schemes for its 5,000 employees. By 1907 the welfare schemes were costing the brewery £40,000 a year, which was one-fifth of the total wages bill. The improvements were suggested and supervised by Sir John Lumsden. By 1914, Guinness was producing 2,652,000 barrels of beer a year, which was more than double that of its nearest competitor Bass, and was supplying more than 10 per cent of the total UK beer market. In the 1930s, Guinness became the seventh largest company in the world. Before 1939, if a Guinness brewer wished to marry a Catholic, his resignation was requested. According to Thomas Molloy, writing in the Irish Independent, “It had no qualms about selling drink to Catholics but it did everything it could to avoid employing them until the 1960s.” Guinness thought they brewed their last porter in 1973. In the 1970s, following declining sales, the decision was taken to make Guinness Extra Stout more “drinkable”. The gravity was subsequently reduced, and the brand was relaunched in 1981. Pale malt was used for the first time, and isomerized hop extract began to be used. In 2014, two new porters were introduced: West Indies Porter and Dublin Porter. Guinness acquired the Distillers Company in 1986.This led to a scandal and criminal trialconcerning the artificial inflation of the Guinness share price during the takeover bid engineered by the chairman, Ernest Saunders. A subsequent £5.2 million success fee paid to an American lawyer and Guinness director, Tom Ward, was the subject of the case Guinness plc v Saunders, in which the House of Lords declared that the payment had been invalid. In the 1980s, as the IRA’s bombing campaign spread to London and the rest of Britain, Guinness considered scrapping the Harp as its logo. The company merged with Grand Metropolitan in 1997 to form Diageo. Due to controversy over the merger, the company was maintained as a separate entity within Diageo and has retained the rights to the product and all associated trademarks of Guinness.The Guinness brewery in Park Royal, London closed in 2005. The production of all Guinness sold in the UK and Ireland was moved to St. James’s Gate Brewery, Dublin. Guinness has also been referred to as “that black stuff”. Guinness had a fleet of ships, barges and yachts. The Irish Sunday Independent newspaper reported on 17 June 2007 that Diageo intended to close the historic St James’s Gate plant in Dublin and move to a greenfield site on the outskirts of the city.This news caused some controversy when it was announced.The following day, the Irish Daily Mail ran a follow-up story with a double page spread complete with images and a history of the plant since 1759. Initially, Diageo said that talk of a move was pure speculation but in the face of mounting speculation in the wake of the Sunday Independent article, the company confirmed that it is undertaking a “significant review of its operations”. This review was largely due to the efforts of the company’s ongoing drive to reduce the environmental impact of brewing at the St James’s Gate plant. On 23 November 2007, an article appeared in the Evening Herald, a Dublin newspaper, stating that the Dublin City Council, in the best interests of the city of Dublin, had put forward a motion to prevent planning permission ever being granted for development of the site, thus making it very difficult for Diageo to sell off the site for residential development. On 9 May 2008, Diageo announced that the St James’s Gate brewery will remain open and undergo renovations, but that breweries in Kilkenny and Dundalk will be closed by 2013 when a new larger brewery is opened near Dublin. The result will be a loss of roughly 250 jobs across the entire Diageo/Guinness workforce in Ireland.Two days later, the Sunday Independent again reported that Diageo chiefs had met with Tánaiste Mary Coughlan, the deputy leader of the Government of Ireland, about moving operations to Ireland from the UK to benefit from its lower corporation tax rates. Several UK firms have made the move in order to pay Ireland’s 12.5 per cent rate rather than the UK’s 28 per cent rate. Diageo released a statement to the London stock exchange denying the report.Despite the merger that created Diageo plc in 1997, Guinness has retained its right to the Guinness brand and associated trademarks and thus continues to trade under the traditional Guinness name despite trading under the corporation name Diageo for a brief period in 1997. In November 2015 it was announced that Guinness are planning to make their beer suitable for consumption by vegetarians and vegans by the end of 2016 through the introduction of a new filtration process at their existing Guinness Brewery that avoids the need to use isinglass from fish bladders to filter out yeast particles.This went into effect in 2017, per the company’s FAQ webpage where they state: “Our new filtration process has removed the use of isinglass as a means of filtration and vegans can now enjoy a pint of Guinness. All Guinness Draught in keg format is brewed without using isinglass. Full distribution of bottle and can formats will be in place by the end of 2017, so until then, our advice to vegans is to consume the product from the keg format only for now. Guinness stout is made from water, barley, roast malt extract, hops, and brewer’s yeast. A portion of the barley is roasted to give Guinness its dark colour and characteristic taste. It is pasteurisedand filtered. Until the late 1950s Guinness was still racked into wooden casks. In the late 1950s and early 1960s, Guinness ceased brewing cask-conditioned beers and developed a keg brewing system with aluminium kegs replacing the wooden casks; these were nicknamed “iron lungs”.Until 2016 the production of Guinness, as with many beers, involved the use of isinglass made from fish. Isinglass was used as a fining agent for settling out suspended matter in the vat. The isinglass was retained in the floor of the vat but it was possible that minute quantities might be carried over into the beer. Diageo announced in February 2018 that the use of isinglass in draught Guinness was to be discontinued and an alternative clarification agent would be used instead. This has made draught Guinness acceptable to vegans and vegetarians. Arguably its biggest change to date, in 1959 Guinness began using nitrogen, which changed the fundamental texture and flavour of the Guinness of the past as nitrogen bubbles are much smaller than CO2, giving a “creamier” and “smoother” consistency over a sharper and traditional CO2 taste. This step was taken after Michael Ash – a mathematician turned brewer – discovered the mechanism to make this possible. Nitrogen is less soluble than carbon dioxide, which allows the beer to be put under high pressure without making it fizzy. High pressure of the dissolved gas is required to enable very small bubbles to be formed by forcing the draught beer through fine holes in a plate in the tap, which causes the characteristic “surge” (the widget in cans and bottles achieves the same effect). This “widget” is a small plastic ball containing the nitrogen. The perceived smoothness of draught Guinness is due to its low level of carbon dioxide and the creaminess of the head caused by the very fine bubbles that arise from the use of nitrogen and the dispensing method described above. “Foreign Extra Stout” contains more carbon dioxide, causing a more acidic taste. Contemporary Guinness Draught and Extra Stout are weaker than they were in the 19th century, when they had an original gravity of over 1.070. Foreign Extra Stout and Special Export Stout, with abv of 7.5% and 9% respectively, are perhaps closest to the original in character.Although Guinness may appear to be black, it is officially a very dark shade of ruby. The most recent change in alcohol content from the Import Stout to the Extra Stout was due to a change in distribution through North American market. Consumer complaints have influenced recent distribution and bottle changes. Studies claim that Guinness can be beneficial to the heart. Researchers found that “‘antioxidantcompounds’ in the Guinness, similar to those found in certain fruits and vegetables, are responsible for the health benefits because they slow down the deposit of harmful cholesterol on the artery walls.”Guinness ran an advertising campaign in the 1920s which stemmed from market research – when people told the company that they felt good after their pint, the slogan, created by Dorothy L. Sayers–”Guinness is Good for You”. Advertising for alcoholic drinks that implies improved physical performance or enhanced personal qualities is now prohibited in Ireland.Diageo, the company that now manufactures Guinness, says: “We never make any medical claims for our drinks.” -

37cm x 47cm Limerick Colman's (est. in 1814) is an English manufacturer of mustard and other sauces, formerly based and produced for 160 years at Carrow, in Norwich, Norfolk. Owned by Unilever since 1995, Colman's is one of the oldest existing food brands, famous for a limited range of products, almost all varieties of mustard. In 2019 the Colman’s factory in Norwich rolled its last jar of mustard off the production line and its Use By Date was changed for the occasion to: "Norwich's Last. By Its Finest. July 24th 2019". Colman’s continued making other condiments at the Carrow site until closing its doors in early 2020. In the early 1800s, Jeremiah Colman began making mustard at a water mill near Norwich in the village of Bawburgh. To create a tangy flavour, he blended brown mustard (Brassica juncea) with white mustard (Sinapis alba). Jeremiah founded Colman's of Norwich in 1814, at the Stoke Holy Cross mill on the River Tas, four miles south of Norwich. In 1823 he took his adopted nephew, James, into the business which became J. & J. Colman. In 1851 J.J. Colman took over the business. By 1865 production had transferred to a large factory at Carrow Road on land at Thorpe Hamlet, bought from the Norfolk Railway to the south of Norwich,where the firm operated until the Norwich closure. From 1855 the firm introduced its distinctive yellow packaging and bull's head logo, and in 1866 was granted the Royal Warrantas manufacturers of mustard to Queen Victoria. Her Majesty's household still uses Colman's today. The Colman family's pioneering achievements in social welfare are part of Norwich's history. In 1857 a school was opened for the employees' children, while in 1864 the firm employed a nurse to help sick members of staff, a social revolution at the time. From 1896 Jeremiah Colman became chairman.In 1903, the firm took over rival mustard maker Keen Robinson & Company,through which it also acquired the Robinsons barley water and baby food business.The purpose of the acquisition was to reduce competition within the mustard business. By 1909 the company employed 2,300 people. Keen's production was moved from London to Norwich in 1925. Together with Reckitt, the company acquired French's, the American mustard manufacturer, in 1926 for £750,000. In 1938 it merged with Reckitts and Sons of Hull to form the Reckitt & Colman household products conglomerate. From 1997 to 2001, Colman's were the main sponsors of Norwich City Football Club. The Colman's part of the business was demerged in 1995 and Colman's became part of Unilever UK Ltd. As well as mustard, it applies its name to condiments, sauces and other foodstuffs. Reckitt and Colman engaged in cost-cutting as it prepared to sell the brand, getting rid of the agronomy department, which had looked after plant breeding and seed development. Colman's maintains links with Norwich. The founding family are commemorated in street names such as Colman Road (part of the A140 inner ring road), on which is situated Colman's First and Middle Schools. In addition, the Colman House residence at the University of East Anglia is named after the company and Jeremiah Colman.

37cm x 47cm Limerick Colman's (est. in 1814) is an English manufacturer of mustard and other sauces, formerly based and produced for 160 years at Carrow, in Norwich, Norfolk. Owned by Unilever since 1995, Colman's is one of the oldest existing food brands, famous for a limited range of products, almost all varieties of mustard. In 2019 the Colman’s factory in Norwich rolled its last jar of mustard off the production line and its Use By Date was changed for the occasion to: "Norwich's Last. By Its Finest. July 24th 2019". Colman’s continued making other condiments at the Carrow site until closing its doors in early 2020. In the early 1800s, Jeremiah Colman began making mustard at a water mill near Norwich in the village of Bawburgh. To create a tangy flavour, he blended brown mustard (Brassica juncea) with white mustard (Sinapis alba). Jeremiah founded Colman's of Norwich in 1814, at the Stoke Holy Cross mill on the River Tas, four miles south of Norwich. In 1823 he took his adopted nephew, James, into the business which became J. & J. Colman. In 1851 J.J. Colman took over the business. By 1865 production had transferred to a large factory at Carrow Road on land at Thorpe Hamlet, bought from the Norfolk Railway to the south of Norwich,where the firm operated until the Norwich closure. From 1855 the firm introduced its distinctive yellow packaging and bull's head logo, and in 1866 was granted the Royal Warrantas manufacturers of mustard to Queen Victoria. Her Majesty's household still uses Colman's today. The Colman family's pioneering achievements in social welfare are part of Norwich's history. In 1857 a school was opened for the employees' children, while in 1864 the firm employed a nurse to help sick members of staff, a social revolution at the time. From 1896 Jeremiah Colman became chairman.In 1903, the firm took over rival mustard maker Keen Robinson & Company,through which it also acquired the Robinsons barley water and baby food business.The purpose of the acquisition was to reduce competition within the mustard business. By 1909 the company employed 2,300 people. Keen's production was moved from London to Norwich in 1925. Together with Reckitt, the company acquired French's, the American mustard manufacturer, in 1926 for £750,000. In 1938 it merged with Reckitts and Sons of Hull to form the Reckitt & Colman household products conglomerate. From 1997 to 2001, Colman's were the main sponsors of Norwich City Football Club. The Colman's part of the business was demerged in 1995 and Colman's became part of Unilever UK Ltd. As well as mustard, it applies its name to condiments, sauces and other foodstuffs. Reckitt and Colman engaged in cost-cutting as it prepared to sell the brand, getting rid of the agronomy department, which had looked after plant breeding and seed development. Colman's maintains links with Norwich. The founding family are commemorated in street names such as Colman Road (part of the A140 inner ring road), on which is situated Colman's First and Middle Schools. In addition, the Colman House residence at the University of East Anglia is named after the company and Jeremiah Colman. -

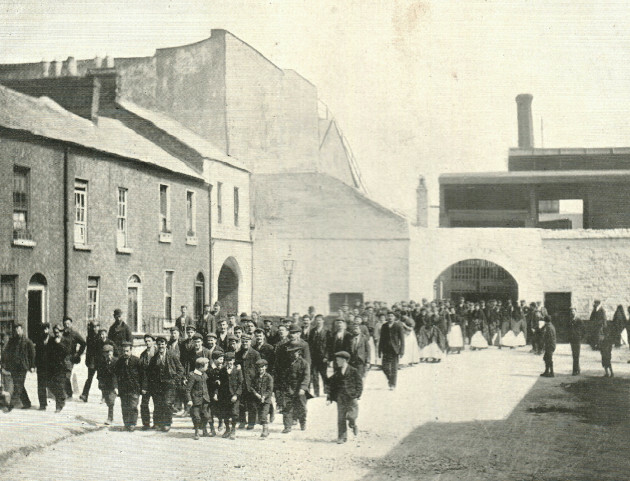

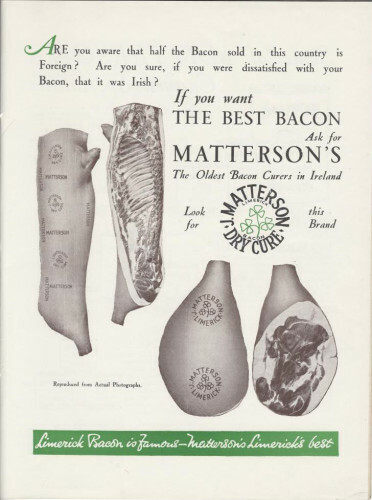

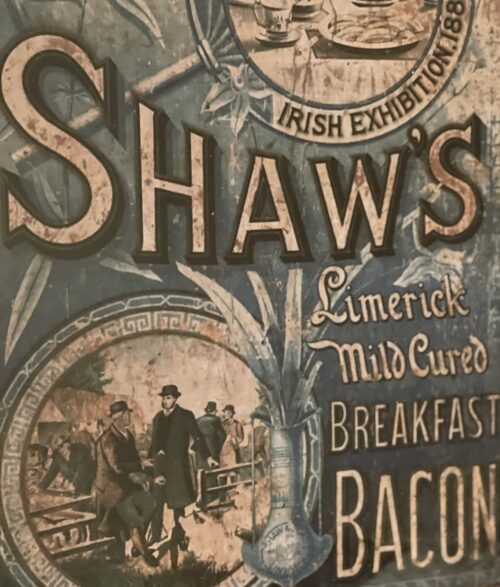

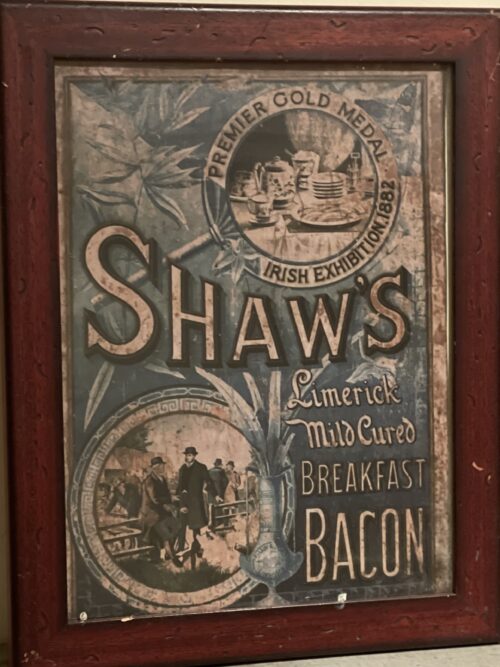

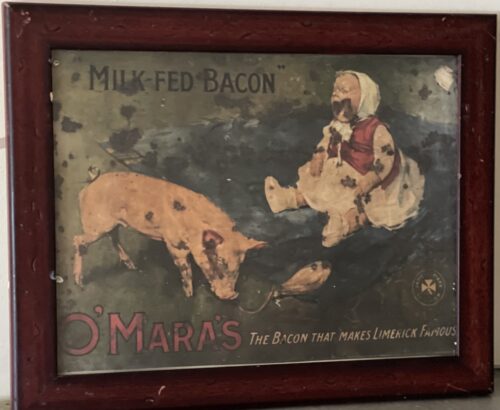

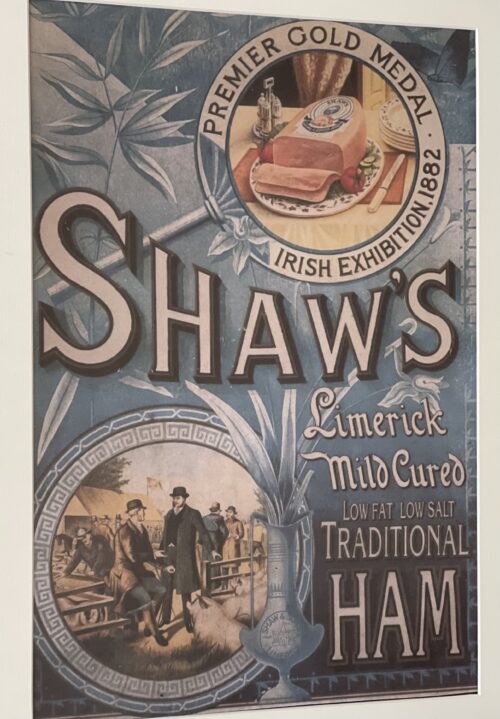

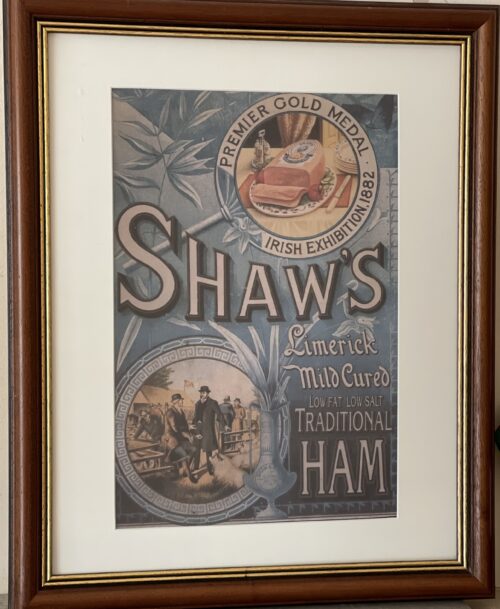

47cm x 37cm LimerickFor much of the last century, and indeed for well over half of the present one, Limerick's importance was directly attributed to her three well-known bacon factories, namely, J. Matterson & Sons, Roches Street, established in 1816 by Mr. John Russell, a Cumberland man in conjunction with Mr. Matterson, using the method of curing then current in Berwick-on-Tweed. W.J. Shaw & Sons, founded in the year 1831 at Mulgrave Street by William John Shaw, a descendant of a County Down family, and O'Mara's bacon factory, Roches Street, which had its origin in Mungret Street some few years before 1839, when James O'Mara from Toomevara started curing bacon in the basement of his house there. Apparently, this basement business flourished, for in 1839 he moved to Roches Street to the premises it occupies today.About the middle of the last century, for some reason now difficult to fathom, Limerick bacon and especially Limerick hams, became well known for their excellent flavour throughout the English-speaking world. It is on record that Glasgow curers in an effort to produce hams equal in excellence to those of Limerick, imported Limerick workmen who were supposed to know all about the way in which the meat was turned out at home. Apparently, they did not bring secrets with them for their efforts were unsuccessful, There were also much larger bacon factories in parts of the British Isles; for instance, Belfast is reputed to have exported four times the number of hams produced in Limerick, and places like Glasgow and Liverpool had several factories producing very large quantities of bacon as well. None of them, however, quite matched' those produced in the three local factories for flavour and taste. O’MARA’S, MATTERSON’S, SHAW’S and Denny’s were the names that made Limerick famous for its bacon produce for 180 years – earning it the nickname ‘Pigstown’. The reputation of Limerick ham, the food culture that arose from a plentiful supply of cheap products, the story of the pork butchers, the pig buyers, the sounds of the city with factory horns signalling the call to work – all of these still resonate in Limerick in the memories of its citizens and former workers. A definitive account of this industry that operated at the centre of the city, supplied by the farms of rural county Limerick for over 180 years will be documented in a new book called Pigtown – A History of Limerick’s Bacon Industry. Ruth Guiry was commissioned to undertake the research under the guidance of Dr Maura Cronin from Mary Immaculate College and one of the 27 people she interviewed to understand the role the bacon factories had in Limerick was Joe Hayes. Joe Hayes started working in a bacon factory in 1962, aged 16 years old. He worked with his dad, and later on with his two sons until the factory closed in 1986. “When the factory closed, a group of us got our own little unit, we rented it, and produced our own sausages, puddings and things.” It was a huge part of Limerick’s social scene: four generations of Joe’s family worked in bacon factories, with uncles, sisters, brothers, sons and cousins all working in the factory at one time or another: “If one factory was caic, you wouldn’t have a problem getting a job in the other one. And he doesn’t mince his word when talking about the work they did. “They brought the pigs in, we killed the pigs, and prepared the bacon: that’s the way it was in the bacon factories.” When asked about if there were ever animal cruelty protests, he laughs at the idea.

47cm x 37cm LimerickFor much of the last century, and indeed for well over half of the present one, Limerick's importance was directly attributed to her three well-known bacon factories, namely, J. Matterson & Sons, Roches Street, established in 1816 by Mr. John Russell, a Cumberland man in conjunction with Mr. Matterson, using the method of curing then current in Berwick-on-Tweed. W.J. Shaw & Sons, founded in the year 1831 at Mulgrave Street by William John Shaw, a descendant of a County Down family, and O'Mara's bacon factory, Roches Street, which had its origin in Mungret Street some few years before 1839, when James O'Mara from Toomevara started curing bacon in the basement of his house there. Apparently, this basement business flourished, for in 1839 he moved to Roches Street to the premises it occupies today.About the middle of the last century, for some reason now difficult to fathom, Limerick bacon and especially Limerick hams, became well known for their excellent flavour throughout the English-speaking world. It is on record that Glasgow curers in an effort to produce hams equal in excellence to those of Limerick, imported Limerick workmen who were supposed to know all about the way in which the meat was turned out at home. Apparently, they did not bring secrets with them for their efforts were unsuccessful, There were also much larger bacon factories in parts of the British Isles; for instance, Belfast is reputed to have exported four times the number of hams produced in Limerick, and places like Glasgow and Liverpool had several factories producing very large quantities of bacon as well. None of them, however, quite matched' those produced in the three local factories for flavour and taste. O’MARA’S, MATTERSON’S, SHAW’S and Denny’s were the names that made Limerick famous for its bacon produce for 180 years – earning it the nickname ‘Pigstown’. The reputation of Limerick ham, the food culture that arose from a plentiful supply of cheap products, the story of the pork butchers, the pig buyers, the sounds of the city with factory horns signalling the call to work – all of these still resonate in Limerick in the memories of its citizens and former workers. A definitive account of this industry that operated at the centre of the city, supplied by the farms of rural county Limerick for over 180 years will be documented in a new book called Pigtown – A History of Limerick’s Bacon Industry. Ruth Guiry was commissioned to undertake the research under the guidance of Dr Maura Cronin from Mary Immaculate College and one of the 27 people she interviewed to understand the role the bacon factories had in Limerick was Joe Hayes. Joe Hayes started working in a bacon factory in 1962, aged 16 years old. He worked with his dad, and later on with his two sons until the factory closed in 1986. “When the factory closed, a group of us got our own little unit, we rented it, and produced our own sausages, puddings and things.” It was a huge part of Limerick’s social scene: four generations of Joe’s family worked in bacon factories, with uncles, sisters, brothers, sons and cousins all working in the factory at one time or another: “If one factory was caic, you wouldn’t have a problem getting a job in the other one. And he doesn’t mince his word when talking about the work they did. “They brought the pigs in, we killed the pigs, and prepared the bacon: that’s the way it was in the bacon factories.” When asked about if there were ever animal cruelty protests, he laughs at the idea.

They started at 8am and finished at 5.30 working a 40 hour week when the factory closed in 1986, but despite their work, the people who worked in factories often couldn’t afford to buy the expensive cuts of meat. After the expensive cuts were prepared, the offal, the spare ribs, the pigs’ heads would go to the poorer people. “The blood was used to make the pudding, the packet, the tripe was made off the belly. Everything was used off the pig, and it fed Limerick city.” It was a way of life down in Limerick, so when the factories closed, thousands of people working in a bacon factories were out of jobs, and thousands of families were affected. But it wasn’t the competition from big supermarkets that did it – it was free trade. The Danes, the French, the Dutch all started exporting their products here, and Limerick factories didn’t have the money to export to compete. “Michael O’Mara’s funeral was this week – he was the last of the bacon factory managers.” says Joe. “After the Limerick factory closed, he tried doing different bits and pieces, but nothing worked out for him, so he worked in a factory for a couple of years before retiring.” Joe Hayes himself is retired now, and when he buys his meat he gets it in a supermarket. “Meat is meat,” he says.”But if I see the tricolour flag, I’ll still buy it even if it’s dearer.” Pigtown - A History of Limerick’s Bacon Industry by Ruth Guiry is co-edited by Dr Maura Cronin and Jacqui Hayes.People still eat sausages and bacon – where do they think they come from? -

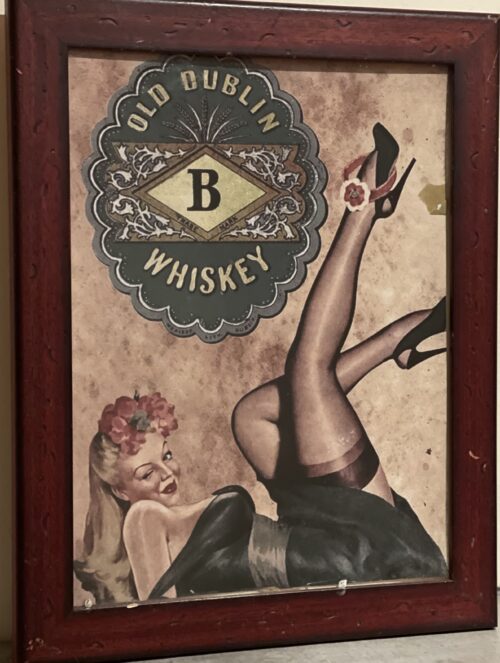

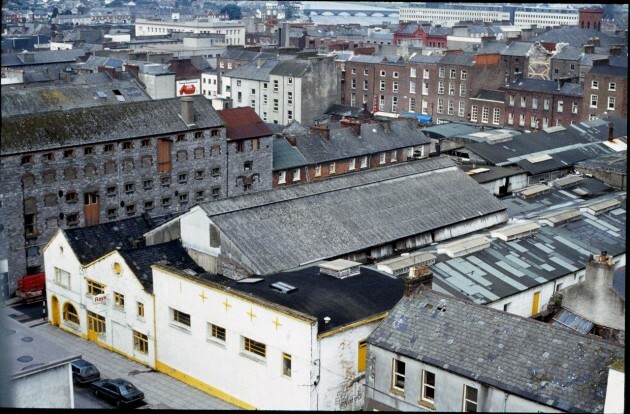

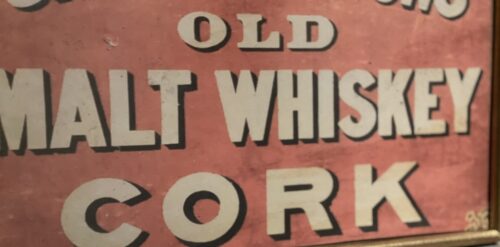

24cm x 40cm The Green Distillery was an Irish whiskey distillery which was established in Cork City, Ireland in 1796. In 1867, the distillery was purchased by the Cork Distilleries Company (CDC), in an amalgamation of five Cork distilleries.Production of whiskey at the distillery likely ceased soon afters its acquisition by the CDC.However, the distillery is known to have remained in use a bonded store by the Cork Distilleries Company for several years thereafter.In the mid-twentieth century, the distillery resumed operations as a gin distillery for a period of time, however, it has since been almost completely demolished. The distillery was notable for its use of an early continuous distillation apparatus, invented by the distillery's then co-owner, Joseph Shee. The distillery began life on 12 May 1796, when two distillers, Robert Allan and Denis Corcoran purchased a dwelling house and maltings on North York Street (now Thomas Davis Street) from Bartholomew Foley, a draper. The malthouse had formerly been owned by Thomas Wood, a maltster, in 1780. In 1802, the Allan and Corcoran are recorded as working a 762 gallon still. In the years that followed, the distillery seems to have changed hands several times. Around 1812, the business was being run by two brothers, Thomas and Joseph Shee, Benjamin Hodges, and some others.Thomas Shee acted as the distiller working a 201 gallon still, while Joseph acted a marketing agent based in London.Hodges and the others may have been silent partners who provided capital but nothing else, as their connection with the distillery soon disappeared. Output was recorded at 100,000 gallons in 1828.In June 1830, the Shees entered financial difficulties, and ownership passed to Joseph Shee. Joseph continued operations using capital provided by James Kiernan under a mortgage, while Thomas Shee remained on as a distiller.In 1833, excise records show that the distillery paid a duty charge of £26,716, which equated to about 160,000 gallons proof.By 1835, Kiernan took outright control of the distillery. When Kiernan died in December 1844, his will specified that the distillery should be put up for sale. It was purchased on 27 July 1845 by George Waters, who was previously a co-owner of Daly's Distillery on John Street, until the dissolution of the partnership following the death of one of the partners. Waters ran the distillery until his retirement around 1867, after which the distillery was purchased by the Cork Distilleries Company (CDC), in an amalgamation of five Cork distilleries. Under CDC, distilling ceased at the distillery in the 1880s, with production transferred to their nearby North Mall distillery. Subsequently, the Green Distillery was used as a bonded store for some time.However, in the mid-twentieth century, new equipment was installed in the Green Distillery, with production of gin occurring there for a period of time. According to Irish Distillers, who absorbed the Cork Distilleries Company in the 1960s, a warehouse on the site was used to store whiskey in bond until the 1980s.Since then, the distillery has been almost completely demolished, with only a small archway remaining. However, one of original pot stills is still in use, currently employed as an experimental still at the nearby New Midleton Distillery.

24cm x 40cm The Green Distillery was an Irish whiskey distillery which was established in Cork City, Ireland in 1796. In 1867, the distillery was purchased by the Cork Distilleries Company (CDC), in an amalgamation of five Cork distilleries.Production of whiskey at the distillery likely ceased soon afters its acquisition by the CDC.However, the distillery is known to have remained in use a bonded store by the Cork Distilleries Company for several years thereafter.In the mid-twentieth century, the distillery resumed operations as a gin distillery for a period of time, however, it has since been almost completely demolished. The distillery was notable for its use of an early continuous distillation apparatus, invented by the distillery's then co-owner, Joseph Shee. The distillery began life on 12 May 1796, when two distillers, Robert Allan and Denis Corcoran purchased a dwelling house and maltings on North York Street (now Thomas Davis Street) from Bartholomew Foley, a draper. The malthouse had formerly been owned by Thomas Wood, a maltster, in 1780. In 1802, the Allan and Corcoran are recorded as working a 762 gallon still. In the years that followed, the distillery seems to have changed hands several times. Around 1812, the business was being run by two brothers, Thomas and Joseph Shee, Benjamin Hodges, and some others.Thomas Shee acted as the distiller working a 201 gallon still, while Joseph acted a marketing agent based in London.Hodges and the others may have been silent partners who provided capital but nothing else, as their connection with the distillery soon disappeared. Output was recorded at 100,000 gallons in 1828.In June 1830, the Shees entered financial difficulties, and ownership passed to Joseph Shee. Joseph continued operations using capital provided by James Kiernan under a mortgage, while Thomas Shee remained on as a distiller.In 1833, excise records show that the distillery paid a duty charge of £26,716, which equated to about 160,000 gallons proof.By 1835, Kiernan took outright control of the distillery. When Kiernan died in December 1844, his will specified that the distillery should be put up for sale. It was purchased on 27 July 1845 by George Waters, who was previously a co-owner of Daly's Distillery on John Street, until the dissolution of the partnership following the death of one of the partners. Waters ran the distillery until his retirement around 1867, after which the distillery was purchased by the Cork Distilleries Company (CDC), in an amalgamation of five Cork distilleries. Under CDC, distilling ceased at the distillery in the 1880s, with production transferred to their nearby North Mall distillery. Subsequently, the Green Distillery was used as a bonded store for some time.However, in the mid-twentieth century, new equipment was installed in the Green Distillery, with production of gin occurring there for a period of time. According to Irish Distillers, who absorbed the Cork Distilleries Company in the 1960s, a warehouse on the site was used to store whiskey in bond until the 1980s.Since then, the distillery has been almost completely demolished, with only a small archway remaining. However, one of original pot stills is still in use, currently employed as an experimental still at the nearby New Midleton Distillery.Notability

The distillery was home to an early continuous distillation apparatus, was which installed and used at the distillery for almost twenty years. The apparatus, which the distiller's co-owner, Joseph Shee, patented in 1834, was similar to Jean‐Édouard Adam's 1801 design, and consisted of a four pot stills connected in series. Though thought to have been effective, the apparatus was not widely adopted. In particular, as a more efficient apparatus, the Coffey Still was patented by another Irish distiller, Aeneas Coffey, in 1830.Daly's Distillery was an Irish whiskey distillery which operated in Cork City, Ireland from around 1820 to 1869. In 1867, the distillery was purchased by the Cork Distilleries Company (CDC), in an amalgamation of five cork distilleries. Two years later, in 1869, as the smallest CDC distillery, Daly's Distillery ceased operations. In the years that followed its closure, some of the buildings became part of Shaw's Flour Mill, and Murphy's Brewery, with others continuing to be used as warehouses by Cork Distilleries Company for several years (though information is difficult to come by, their continued existence is mentioned in Alfred Barnard's 1887 account of the distilleries of the United Kingdom).History

In 1798, the firm of James Daly & Co. was established as a rectifying distillery and wine merchants at a premises on Blarney St., Cork. In 1820, this was relocated to 32 John Street.As some sources state that the John distillery was established in 1807, and it is known that a William Lyons ran a distillery on John Street in the early 1800s, it is possible that Daly purchased an existing distillery on John Street. In 1822, James Daly's nephew John Murray joined the partnership. In 1828, the distillery is reported to have an output of 87,874 gallons of spirit.However, in 1833, output of only 39,000 gallons per annum was reported, which was low compared with some of the Irish distillers of the era; for instance, at that time Murphy's Distillery in nearby Midleton, had an output of over 400,000 gallons per annum. On James Daly's death, in 1850, the partnership, which at that point had consisted of James Daly, Maurice Murray (John Murray's son) and George Waters, was dissolved, with Maurice Murray taking sole ownership of the distillery, which continued to trade as James Daly & Co. After leaving the partnership, George Waters went on to purchase and run the nearby Green distillery. In 1853, Murray rebuilt and significantly extended the distillery, expanding onto neighbouring streets. By the late 1860s, the distillery had grown to occupy 3 acres, consisting of a brewhouse, distillery and maltings on John Street; granaries on Leitrim Street; and eight bonded warehouses scattered across John Street, Leitrim Street and Watercourse Road.According to accounts from the time, whiskey from the distillery, some of which was aged for seven years or more, was mainly exported "to the colonies".In particular, it was said that in Australia the whiskey sold at a premium to other whiskeys. A well respected member of the Irish distilling industry at the time, the distillery's owner Maurice Murray, conducted significant correspondence with William Ewart Gladstone, the then British Chancellor of the Exchequer, on behalf of the Irish distillers, with regard to the duties placed on Irish whiskey. In 1867, Daly's Distillery, was absorbed into Cork Distilleries Company (CDC), in an amalgamation of five Cork distilleries. As the smallest of the five distilleries, Daly's closed soon after the amalgamation, in 1869. Following its closure, Maurice Murray is known to have continued to work for the CDC at the North Mall Distillery, along with his son Daly Murray. The main distillery buildings later became part of Shaw's Flour Mill, while other buildings were incorporated into the nearby Murphy's Brewery, which was run by relatives of James Murphy of the Midleton Distillery, who was the driving force behind the establishment of the Cork Distilleries Company. One of the distillery buildings, now named "the Mill", is still visible on 32 Lower John Street, Cork. -

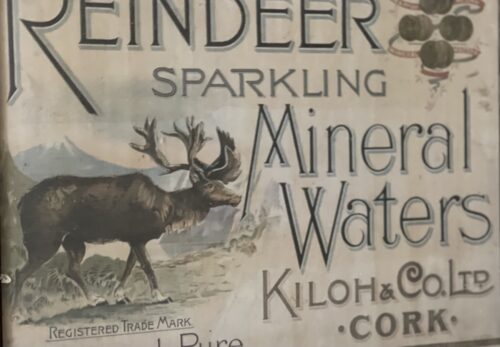

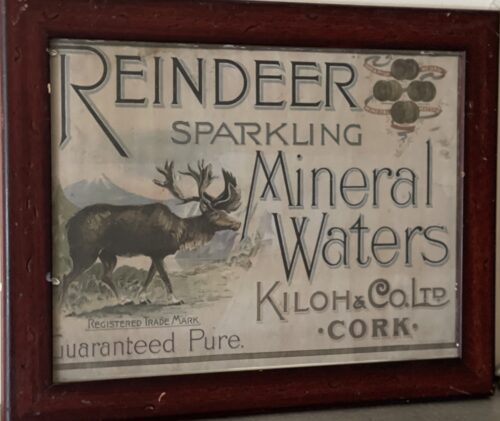

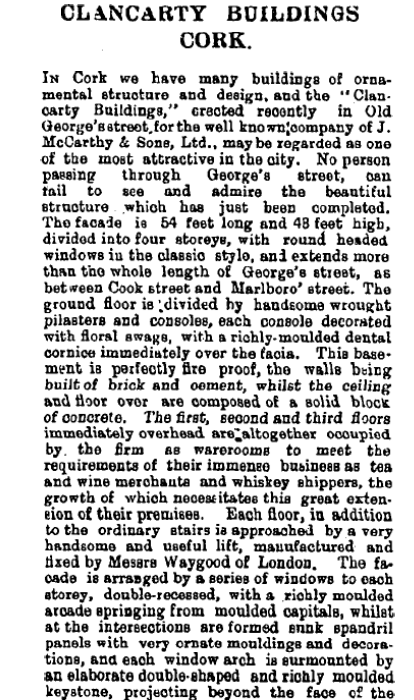

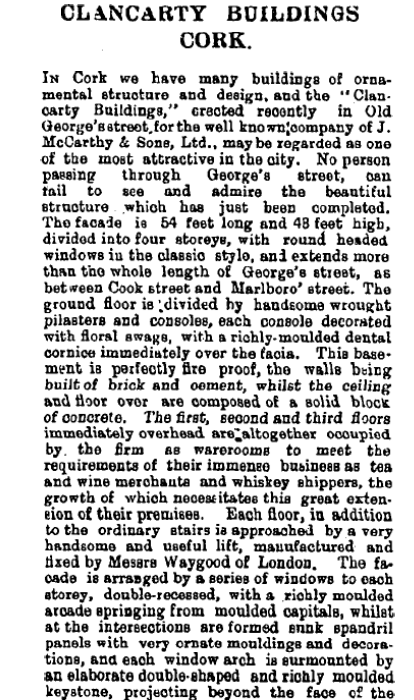

47cm x 37cm Limerick The building itself it is a terraced eight-bay four-storey late-Victorian commercial building, It was built across 1895 and 1896 for J McCarthy and Sons, Wholesale Tea and Wine Merchants. Named the Clancarty (family of Carty) Buildings, the building was designed by architect and built by John Delaney. The Cork Examiner on 10 August 1896 (p.9) describes the impressive building: “No person passing through George’s street, can fail to see and admire the beautiful structure, which has just been completed. The facade is 54 feet long and 48 feet high, divided into four storeys, with round headed windows in the classic style, and extends more than the whole length of George’s Street, as between Cook street and Marlboro Street. The ground floor is divided by handsome wrought pilasters and consoles, each console decorated with floral swags, with a richly-moulded dental cornice immediately over the facia. This basement is perfectly fire proof, the walls being built of brick and cement, whilst the ceiling and floor over are composed of a solid block of concrete. The first, second and third floors immediately overhead are altogether occupied by the firm as warerooms to meet the requirements of their immense business as tea and wine merchants and whiskey shippers, the growth of which necessitates this great extension of their premises”.

47cm x 37cm Limerick The building itself it is a terraced eight-bay four-storey late-Victorian commercial building, It was built across 1895 and 1896 for J McCarthy and Sons, Wholesale Tea and Wine Merchants. Named the Clancarty (family of Carty) Buildings, the building was designed by architect and built by John Delaney. The Cork Examiner on 10 August 1896 (p.9) describes the impressive building: “No person passing through George’s street, can fail to see and admire the beautiful structure, which has just been completed. The facade is 54 feet long and 48 feet high, divided into four storeys, with round headed windows in the classic style, and extends more than the whole length of George’s Street, as between Cook street and Marlboro Street. The ground floor is divided by handsome wrought pilasters and consoles, each console decorated with floral swags, with a richly-moulded dental cornice immediately over the facia. This basement is perfectly fire proof, the walls being built of brick and cement, whilst the ceiling and floor over are composed of a solid block of concrete. The first, second and third floors immediately overhead are altogether occupied by the firm as warerooms to meet the requirements of their immense business as tea and wine merchants and whiskey shippers, the growth of which necessitates this great extension of their premises”.

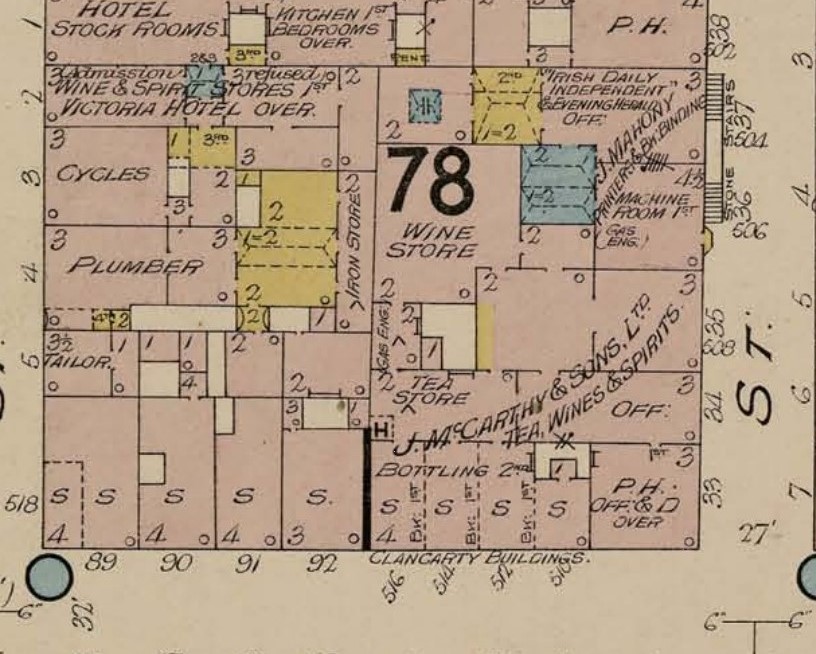

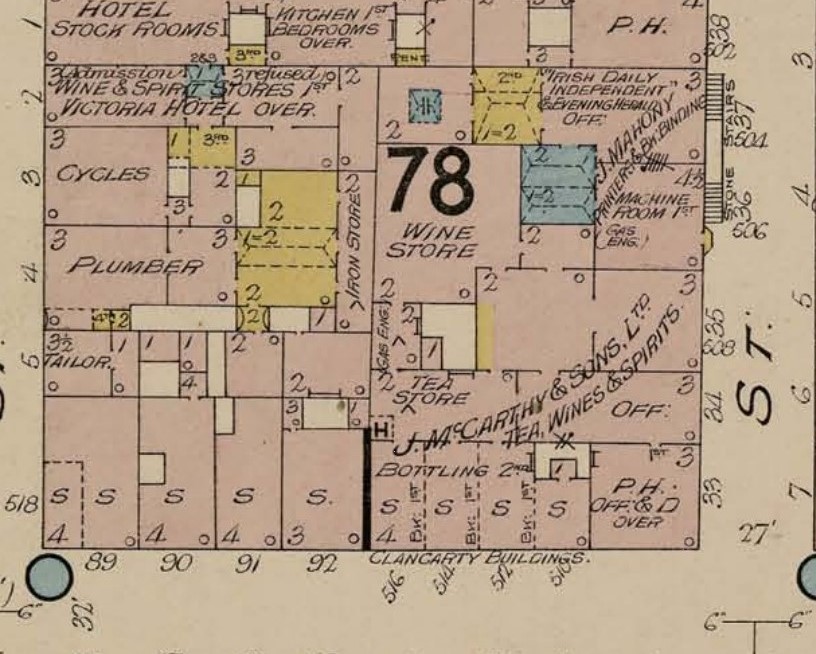

J McCarthy and Sons, Wholesale Tea and Wine Merchants as shown in Goads Insurance Map of Cork, 1906 (source: Kieran McCarthy)

Description of Clancarty Buildings, Cork Examiner, 10 August 1896, p.9 (source: Cork City Library) -

47cm x 37cm Limerick The building itself it is a terraced eight-bay four-storey late-Victorian commercial building, It was built across 1895 and 1896 for J McCarthy and Sons, Wholesale Tea and Wine Merchants. Named the Clancarty (family of Carty) Buildings, the building was designed by architect and built by John Delaney. The Cork Examiner on 10 August 1896 (p.9) describes the impressive building: “No person passing through George’s street, can fail to see and admire the beautiful structure, which has just been completed. The facade is 54 feet long and 48 feet high, divided into four storeys, with round headed windows in the classic style, and extends more than the whole length of George’s Street, as between Cook street and Marlboro Street. The ground floor is divided by handsome wrought pilasters and consoles, each console decorated with floral swags, with a richly-moulded dental cornice immediately over the facia. This basement is perfectly fire proof, the walls being built of brick and cement, whilst the ceiling and floor over are composed of a solid block of concrete. The first, second and third floors immediately overhead are altogether occupied by the firm as warerooms to meet the requirements of their immense business as tea and wine merchants and whiskey shippers, the growth of which necessitates this great extension of their premises”.

47cm x 37cm Limerick The building itself it is a terraced eight-bay four-storey late-Victorian commercial building, It was built across 1895 and 1896 for J McCarthy and Sons, Wholesale Tea and Wine Merchants. Named the Clancarty (family of Carty) Buildings, the building was designed by architect and built by John Delaney. The Cork Examiner on 10 August 1896 (p.9) describes the impressive building: “No person passing through George’s street, can fail to see and admire the beautiful structure, which has just been completed. The facade is 54 feet long and 48 feet high, divided into four storeys, with round headed windows in the classic style, and extends more than the whole length of George’s Street, as between Cook street and Marlboro Street. The ground floor is divided by handsome wrought pilasters and consoles, each console decorated with floral swags, with a richly-moulded dental cornice immediately over the facia. This basement is perfectly fire proof, the walls being built of brick and cement, whilst the ceiling and floor over are composed of a solid block of concrete. The first, second and third floors immediately overhead are altogether occupied by the firm as warerooms to meet the requirements of their immense business as tea and wine merchants and whiskey shippers, the growth of which necessitates this great extension of their premises”.

J McCarthy and Sons, Wholesale Tea and Wine Merchants as shown in Goads Insurance Map of Cork, 1906 (source: Kieran McCarthy)

Description of Clancarty Buildings, Cork Examiner, 10 August 1896, p.9 (source: Cork City Library) -

47cm x 37cm LimerickMuch of the last century, and indeed for well over half of the present one, Limerick's importance was directly attributed to her three well-known bacon factories, namely, J. Matterson & Sons, Roches Street, established in 1816 by Mr. John Russell, a Cumberland man in con-junction with Mr. Matterson, using the method of curing then current in Berwick-on-Tweed. W.J. Shaw & Sons, founded in the year 1831 at Mulgrave Street by William John Shaw, a descendant of a County Down family, and O'Mara's bacon factory, Roches Street, which had its origin in Mungret Street some few years before 1839, when James O'Mara from Toomevara started curing bacon in the basement of his house there. Apparently, this basement business flourished, for in 1839 he moved to Roches Street to the premises it last occupied .About the middle of the last century, for some reason now difficult to fathom, Limerick bacon and especially Limerick hams, became well-known for their excellent flavour throughout the English-speaking world. It is on record that Glasgow curers in an effort to produce hams equal in excellence to those of Limerick, imported Limerick workmen who were supposed to know all about the way in which the meat was turned out at home. Apparently, they did not bring secrets with them for their efforts were unsuccessful. There were also much larger bacon factories in parts of the British Isles; for instance, Belfast is reputed to have exported four times the number of hams produced in Limerick, and places like Glasgow and Liverpool had several factories producing very large quantities of bacon as well. None of them, however, quite matched' those produced in the three local factories for flavour and quality.O’MARA’S, MATTERSON’S, SHAW’S and Denny’s were the names that made Limerick famous for its bacon produce for 180 years – earning it the nickname ‘Pigstown’. The reputation of Limerick ham, the food culture that arose from a plentiful supply of cheap products, the story of the pork butchers, the pig buyers, the sounds of the city with factory horns signalling the call to work – all of these still resonate in Limerick in the memories of its citizens and former workers. A definitive account of this industry that operated at the centre of the city, supplied by the farms of rural county Limerick for over 180 years will be documented in a new book called Pigtown – A History of Limerick’s Bacon Industry. Ruth Guiry was commissioned to undertake the research under the guidance of Dr Maura Cronin from Mary Immaculate College and one of the 27 people she interviewed to understand the role the bacon factories had in Limerick was Joe Hayes. Joe Hayes started working in a bacon factory in 1962, aged 16 years old. He worked with his dad, and later on with his two sons until the factory closed in 1986. “When the factory closed, a group of us got our own little unit, we rented it, and produced our own sausages, puddings and things.” It was a huge part of Limerick’s social scene: four generations of Joe’s family worked in bacon factories, with uncles, sisters, brothers, sons and cousins all working in the factory at one time or another: “If one factory was caic, you wouldn’t have a problem getting a job in the other one. And he doesn’t mince his word when talking about the work they did. “They brought the pigs in, we killed the pigs, and prepared the bacon: that’s the way it was in the bacon factories.” When asked about if there were ever animal cruelty protests, he laughs at the idea.

47cm x 37cm LimerickMuch of the last century, and indeed for well over half of the present one, Limerick's importance was directly attributed to her three well-known bacon factories, namely, J. Matterson & Sons, Roches Street, established in 1816 by Mr. John Russell, a Cumberland man in con-junction with Mr. Matterson, using the method of curing then current in Berwick-on-Tweed. W.J. Shaw & Sons, founded in the year 1831 at Mulgrave Street by William John Shaw, a descendant of a County Down family, and O'Mara's bacon factory, Roches Street, which had its origin in Mungret Street some few years before 1839, when James O'Mara from Toomevara started curing bacon in the basement of his house there. Apparently, this basement business flourished, for in 1839 he moved to Roches Street to the premises it last occupied .About the middle of the last century, for some reason now difficult to fathom, Limerick bacon and especially Limerick hams, became well-known for their excellent flavour throughout the English-speaking world. It is on record that Glasgow curers in an effort to produce hams equal in excellence to those of Limerick, imported Limerick workmen who were supposed to know all about the way in which the meat was turned out at home. Apparently, they did not bring secrets with them for their efforts were unsuccessful. There were also much larger bacon factories in parts of the British Isles; for instance, Belfast is reputed to have exported four times the number of hams produced in Limerick, and places like Glasgow and Liverpool had several factories producing very large quantities of bacon as well. None of them, however, quite matched' those produced in the three local factories for flavour and quality.O’MARA’S, MATTERSON’S, SHAW’S and Denny’s were the names that made Limerick famous for its bacon produce for 180 years – earning it the nickname ‘Pigstown’. The reputation of Limerick ham, the food culture that arose from a plentiful supply of cheap products, the story of the pork butchers, the pig buyers, the sounds of the city with factory horns signalling the call to work – all of these still resonate in Limerick in the memories of its citizens and former workers. A definitive account of this industry that operated at the centre of the city, supplied by the farms of rural county Limerick for over 180 years will be documented in a new book called Pigtown – A History of Limerick’s Bacon Industry. Ruth Guiry was commissioned to undertake the research under the guidance of Dr Maura Cronin from Mary Immaculate College and one of the 27 people she interviewed to understand the role the bacon factories had in Limerick was Joe Hayes. Joe Hayes started working in a bacon factory in 1962, aged 16 years old. He worked with his dad, and later on with his two sons until the factory closed in 1986. “When the factory closed, a group of us got our own little unit, we rented it, and produced our own sausages, puddings and things.” It was a huge part of Limerick’s social scene: four generations of Joe’s family worked in bacon factories, with uncles, sisters, brothers, sons and cousins all working in the factory at one time or another: “If one factory was caic, you wouldn’t have a problem getting a job in the other one. And he doesn’t mince his word when talking about the work they did. “They brought the pigs in, we killed the pigs, and prepared the bacon: that’s the way it was in the bacon factories.” When asked about if there were ever animal cruelty protests, he laughs at the idea.

They started at 8am and finished at 5.30 working a 40 hour week when the factory closed in 1986, but despite their work, the people who worked in factories often couldn’t afford to buy the expensive cuts of meat. After the expensive cuts were prepared, the offal, the spare ribs, the pigs’ heads would go to the poorer people. “The blood was used to make the pudding, the packet, the tripe was made off the belly. Everything was used off the pig, and it fed Limerick city.” It was a way of life down in Limerick, so when the factories closed, thousands of people working in a bacon factories were out of jobs, and thousands of families were affected. But it wasn’t the competition from big supermarkets that did it – it was free trade. The Danes, the French, the Dutch all started exporting their products here, and Limerick factories didn’t have the money to export to compete. “Michael O’Mara’s funeral was this week – he was the last of the bacon factory managers.” says Joe. “After the Limerick factory closed, he tried doing different bits and pieces, but nothing worked out for him, so he worked in a factory for a couple of years before retiring.” Joe Hayes himself is retired now, and when he buys his meat he gets it in a supermarket. “Meat is meat,” he says.”But if I see the tricolour flag, I’ll still buy it even if it’s dearer.” Pigtown - A History of Limerick’s Bacon Industry by Ruth Guiry is co-edited by Dr Maura Cronin and Jacqui Hayes.People still eat sausages and bacon – where do they think they come from? -

40cm x 34cm LimerickMuch of the last century, and indeed for well over half of the present one, Limerick's importance was directly attributed to her three well-known bacon factories, namely, J. Matterson & Sons, Roches Street, established in 1816 by Mr. John Russell, a Cumberland man in con-junction with Mr. Matterson, using the method of curing then current in Berwick-on-Tweed. W.J. Shaw & Sons, founded in the year 1831 at Mulgrave Street by William John Shaw, a descendant of a County Down family, and O'Mara's bacon factory, Roches Street, which had its origin in Mungret Street some few years before 1839, when James O'Mara from Toomevara started curing bacon in the basement of his house there. Apparently, this basement business flourished, for in 1839 he moved to Roches Street to the premises it last occupied .About the middle of the last century, for some reason now difficult to fathom, Limerick bacon and especially Limerick hams, became well-known for their excellent flavour throughout the English-speaking world. It is on record that Glasgow curers in an effort to produce hams equal in excellence to those of Limerick, imported Limerick workmen who were supposed to know all about the way in which the meat was turned out at home. Apparently, they did not bring secrets with them for their efforts were unsuccessful. There were also much larger bacon factories in parts of the British Isles; for instance, Belfast is reputed to have exported four times the number of hams produced in Limerick, and places like Glasgow and Liverpool had several factories producing very large quantities of bacon as well. None of them, however, quite matched' those produced in the three local factories for flavour and quality.O’MARA’S, MATTERSON’S, SHAW’S and Denny’s were the names that made Limerick famous for its bacon produce for 180 years – earning it the nickname ‘Pigstown’. The reputation of Limerick ham, the food culture that arose from a plentiful supply of cheap products, the story of the pork butchers, the pig buyers, the sounds of the city with factory horns signalling the call to work – all of these still resonate in Limerick in the memories of its citizens and former workers. A definitive account of this industry that operated at the centre of the city, supplied by the farms of rural county Limerick for over 180 years will be documented in a new book called Pigtown – A History of Limerick’s Bacon Industry. Ruth Guiry was commissioned to undertake the research under the guidance of Dr Maura Cronin from Mary Immaculate College and one of the 27 people she interviewed to understand the role the bacon factories had in Limerick was Joe Hayes. Joe Hayes started working in a bacon factory in 1962, aged 16 years old. He worked with his dad, and later on with his two sons until the factory closed in 1986. “When the factory closed, a group of us got our own little unit, we rented it, and produced our own sausages, puddings and things.” It was a huge part of Limerick’s social scene: four generations of Joe’s family worked in bacon factories, with uncles, sisters, brothers, sons and cousins all working in the factory at one time or another: “If one factory was caic, you wouldn’t have a problem getting a job in the other one. And he doesn’t mince his word when talking about the work they did. “They brought the pigs in, we killed the pigs, and prepared the bacon: that’s the way it was in the bacon factories.” When asked about if there were ever animal cruelty protests, he laughs at the idea.