-

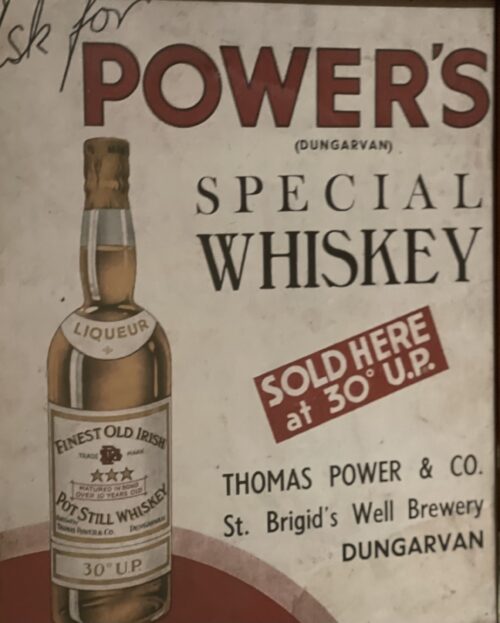

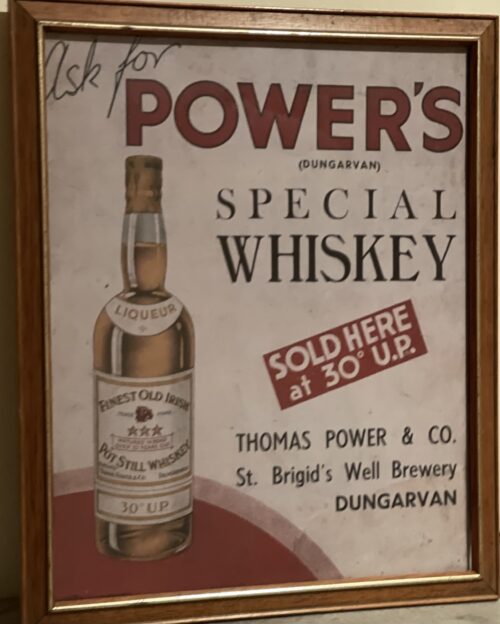

42cm x 32cm LimerickThomas Power (1856-1930) was the first chairman of Waterford County Council and was chairman of Dungarvan Town Commissioners on a number of occasions. In the 1880s he was in partnership with his brother producing mineral waters. In 1904 he began producing his award winning Blackwater Cider. In 1917 Thomas purchased the old St Brigid's Well Brewery in Fair Lane, Dungarvan from the Marquis of Waterford. The business was a great success and its produce was in demand all over County Waterford and beyond. After his death the brewery was taken over by his son Paul I. Power who managed it until 1976 when his son Ion took over. Brewing took place in Dungarvan throughout history but we only have detailed information from the late 18th century onwards. In 1917 the Marquis sold the property and it was acquired by Thomas Power. He developed a thriving business known as Power's Brewery. This brewing tradition continues into the modern era with the Dungarvan Brewing Company.

42cm x 32cm LimerickThomas Power (1856-1930) was the first chairman of Waterford County Council and was chairman of Dungarvan Town Commissioners on a number of occasions. In the 1880s he was in partnership with his brother producing mineral waters. In 1904 he began producing his award winning Blackwater Cider. In 1917 Thomas purchased the old St Brigid's Well Brewery in Fair Lane, Dungarvan from the Marquis of Waterford. The business was a great success and its produce was in demand all over County Waterford and beyond. After his death the brewery was taken over by his son Paul I. Power who managed it until 1976 when his son Ion took over. Brewing took place in Dungarvan throughout history but we only have detailed information from the late 18th century onwards. In 1917 the Marquis sold the property and it was acquired by Thomas Power. He developed a thriving business known as Power's Brewery. This brewing tradition continues into the modern era with the Dungarvan Brewing Company. -

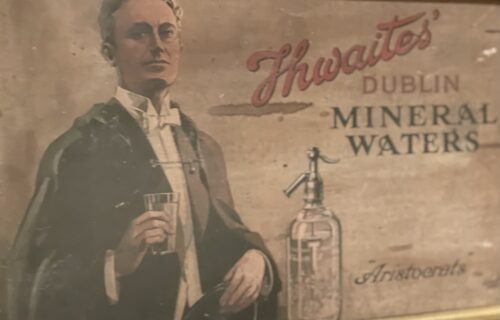

24cm x 40cm Thwaite’s Mineral Waters had been established by Dublin chemist Augustine Thwaite in the late 1700s. Thwaite’s would amalgamate with a number of other firms, including the Belfast firm of Cantrell & Cochrane, to form Mineral Water Distributers (from whence derives the name ‘MiWadi’) in 1927.

24cm x 40cm Thwaite’s Mineral Waters had been established by Dublin chemist Augustine Thwaite in the late 1700s. Thwaite’s would amalgamate with a number of other firms, including the Belfast firm of Cantrell & Cochrane, to form Mineral Water Distributers (from whence derives the name ‘MiWadi’) in 1927.Truly one of humanity’s truly great inventions is – carbonated water. How dull our taste buds would be without it! How impossible would be hangovers (so I’m told!). How . . . well . . . flat life would be!

And all down to an 18th century English Protestant minister Rev Joseph Priestly who invented soda water by accident in 1769. (What results when carbon dioxide gas is dissolved in water under pressure.)

He published a paper on it titled, ahem, Impregnating Water with Fixed Air. As you do.

Along came German-Swiss watchmaker Johann Jacob Schweppe who took Priestly’s invention and manufactured bottled carbonated mineral water. In 1792 he moved to London to develop the Schweppes business there and, in 1799, Augustine Thwaites founded Thwaites’ Soda Water in the fair city of Dublin.

It was Thwaites who first used (and patented) the term “soda water” to describe the fizzy drink. That arose from noticing that adding sodium carbonate to water greatly facilitated the absorption of carbon dioxide. Which is where the American term “soda” came from.

Those bubbles harm nothing. The carbon dioxide is always with us. It is just squashed under pressure into water. Cheers!

Carbon, from Latin carbonem, for “a coal, glowing coal, charcoal”.

-

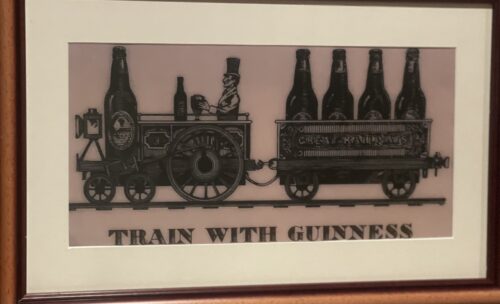

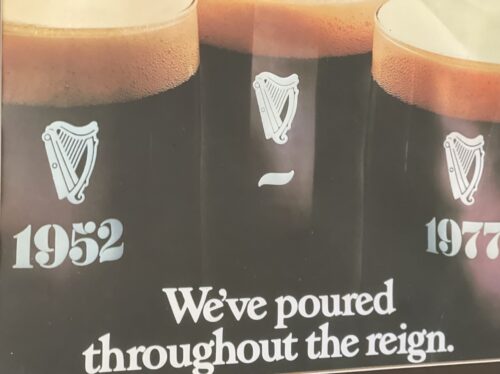

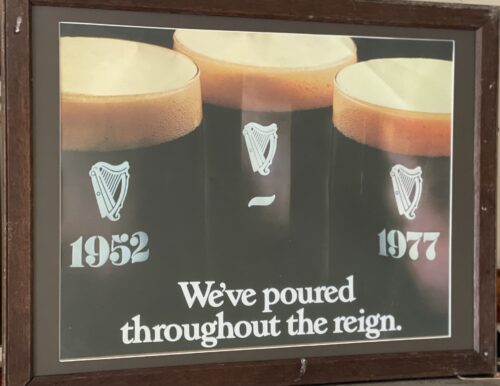

38cm x 57cm Arthur Guinness started brewing ales in 1759 at the St James Gate Brewery,Dublin.On 31st December 1759 he signed a 9,000 year lease at £45 per annum for the unused brewery.Ten years later, on 19 May 1769, Guinness first exported his ale: he shipped six-and-a-half barrels to Great Britain before he started selling the dark beer porter in 1778. The first Guinness beers to use the term were Single Stout and Double Stout in the 1840s.Throughout the bulk of its history, Guinness produced only three variations of a single beer type: porter or single stout, double or extra and foreign stout for export. “Stout” originally referred to a beer’s strength, but eventually shifted meaning toward body and colour.Porter was also referred to as “plain”, as mentioned in the famous refrain of Flann O’Brien‘s poem “The Workman’s Friend”: “A pint of plain is your only man.” Already one of the top-three British and Irish brewers, Guinness’s sales soared from 350,000 barrels in 1868 to 779,000 barrels in 1876.In October 1886 Guinness became a public company, and was averaging sales of 1,138,000 barrels a year. This was despite the brewery’s refusal to either advertise or offer its beer at a discount. Even though Guinness owned no public houses, the company was valued at £6 million and shares were twenty times oversubscribed, with share prices rising to a 60 per cent premium on the first day of trading. The breweries pioneered several quality control efforts. The brewery hired the statistician William Sealy Gosset in 1899, who achieved lasting fame under the pseudonym “Student” for techniques developed for Guinness, particularly Student’s t-distribution and the even more commonly known Student’s t-test. By 1900 the brewery was operating unparalleled welfare schemes for its 5,000 employees. By 1907 the welfare schemes were costing the brewery £40,000 a year, which was one-fifth of the total wages bill. The improvements were suggested and supervised by Sir John Lumsden. By 1914, Guinness was producing 2,652,000 barrels of beer a year, which was more than double that of its nearest competitor Bass, and was supplying more than 10 per cent of the total UK beer market. In the 1930s, Guinness became the seventh largest company in the world. Before 1939, if a Guinness brewer wished to marry a Catholic, his resignation was requested. According to Thomas Molloy, writing in the Irish Independent, “It had no qualms about selling drink to Catholics but it did everything it could to avoid employing them until the 1960s.” Guinness thought they brewed their last porter in 1973. In the 1970s, following declining sales, the decision was taken to make Guinness Extra Stout more “drinkable”. The gravity was subsequently reduced, and the brand was relaunched in 1981. Pale malt was used for the first time, and isomerized hop extract began to be used. In 2014, two new porters were introduced: West Indies Porter and Dublin Porter. Guinness acquired the Distillers Company in 1986.This led to a scandal and criminal trialconcerning the artificial inflation of the Guinness share price during the takeover bid engineered by the chairman, Ernest Saunders. A subsequent £5.2 million success fee paid to an American lawyer and Guinness director, Tom Ward, was the subject of the case Guinness plc v Saunders, in which the House of Lords declared that the payment had been invalid. In the 1980s, as the IRA’s bombing campaign spread to London and the rest of Britain, Guinness considered scrapping the Harp as its logo. The company merged with Grand Metropolitan in 1997 to form Diageo. Due to controversy over the merger, the company was maintained as a separate entity within Diageo and has retained the rights to the product and all associated trademarks of Guinness.The Guinness brewery in Park Royal, London closed in 2005. The production of all Guinness sold in the UK and Ireland was moved to St. James’s Gate Brewery, Dublin. Guinness has also been referred to as “that black stuff”. Guinness had a fleet of ships, barges and yachts. The Irish Sunday Independent newspaper reported on 17 June 2007 that Diageo intended to close the historic St James’s Gate plant in Dublin and move to a greenfield site on the outskirts of the city.This news caused some controversy when it was announced.The following day, the Irish Daily Mail ran a follow-up story with a double page spread complete with images and a history of the plant since 1759. Initially, Diageo said that talk of a move was pure speculation but in the face of mounting speculation in the wake of the Sunday Independent article, the company confirmed that it is undertaking a “significant review of its operations”. This review was largely due to the efforts of the company’s ongoing drive to reduce the environmental impact of brewing at the St James’s Gate plant. On 23 November 2007, an article appeared in the Evening Herald, a Dublin newspaper, stating that the Dublin City Council, in the best interests of the city of Dublin, had put forward a motion to prevent planning permission ever being granted for development of the site, thus making it very difficult for Diageo to sell off the site for residential development. On 9 May 2008, Diageo announced that the St James’s Gate brewery will remain open and undergo renovations, but that breweries in Kilkenny and Dundalk will be closed by 2013 when a new larger brewery is opened near Dublin. The result will be a loss of roughly 250 jobs across the entire Diageo/Guinness workforce in Ireland.Two days later, the Sunday Independent again reported that Diageo chiefs had met with Tánaiste Mary Coughlan, the deputy leader of the Government of Ireland, about moving operations to Ireland from the UK to benefit from its lower corporation tax rates. Several UK firms have made the move in order to pay Ireland’s 12.5 per cent rate rather than the UK’s 28 per cent rate. Diageo released a statement to the London stock exchange denying the report.Despite the merger that created Diageo plc in 1997, Guinness has retained its right to the Guinness brand and associated trademarks and thus continues to trade under the traditional Guinness name despite trading under the corporation name Diageo for a brief period in 1997. In November 2015 it was announced that Guinness are planning to make their beer suitable for consumption by vegetarians and vegans by the end of 2016 through the introduction of a new filtration process at their existing Guinness Brewery that avoids the need to use isinglass from fish bladders to filter out yeast particles.This went into effect in 2017, per the company’s FAQ webpage where they state: “Our new filtration process has removed the use of isinglass as a means of filtration and vegans can now enjoy a pint of Guinness. All Guinness Draught in keg format is brewed without using isinglass. Full distribution of bottle and can formats will be in place by the end of 2017, so until then, our advice to vegans is to consume the product from the keg format only for now. Guinness stout is made from water, barley, roast malt extract, hops, and brewer’s yeast. A portion of the barley is roasted to give Guinness its dark colour and characteristic taste. It is pasteurisedand filtered. Until the late 1950s Guinness was still racked into wooden casks. In the late 1950s and early 1960s, Guinness ceased brewing cask-conditioned beers and developed a keg brewing system with aluminium kegs replacing the wooden casks; these were nicknamed “iron lungs”.Until 2016 the production of Guinness, as with many beers, involved the use of isinglass made from fish. Isinglass was used as a fining agent for settling out suspended matter in the vat. The isinglass was retained in the floor of the vat but it was possible that minute quantities might be carried over into the beer. Diageo announced in February 2018 that the use of isinglass in draught Guinness was to be discontinued and an alternative clarification agent would be used instead. This has made draught Guinness acceptable to vegans and vegetarians. Arguably its biggest change to date, in 1959 Guinness began using nitrogen, which changed the fundamental texture and flavour of the Guinness of the past as nitrogen bubbles are much smaller than CO2, giving a “creamier” and “smoother” consistency over a sharper and traditional CO2 taste. This step was taken after Michael Ash – a mathematician turned brewer – discovered the mechanism to make this possible. Nitrogen is less soluble than carbon dioxide, which allows the beer to be put under high pressure without making it fizzy. High pressure of the dissolved gas is required to enable very small bubbles to be formed by forcing the draught beer through fine holes in a plate in the tap, which causes the characteristic “surge” (the widget in cans and bottles achieves the same effect). This “widget” is a small plastic ball containing the nitrogen. The perceived smoothness of draught Guinness is due to its low level of carbon dioxide and the creaminess of the head caused by the very fine bubbles that arise from the use of nitrogen and the dispensing method described above. “Foreign Extra Stout” contains more carbon dioxide, causing a more acidic taste. Contemporary Guinness Draught and Extra Stout are weaker than they were in the 19th century, when they had an original gravity of over 1.070. Foreign Extra Stout and Special Export Stout, with abv of 7.5% and 9% respectively, are perhaps closest to the original in character.Although Guinness may appear to be black, it is officially a very dark shade of ruby. The most recent change in alcohol content from the Import Stout to the Extra Stout was due to a change in distribution through North American market. Consumer complaints have influenced recent distribution and bottle changes. Studies claim that Guinness can be beneficial to the heart. Researchers found that “‘antioxidantcompounds’ in the Guinness, similar to those found in certain fruits and vegetables, are responsible for the health benefits because they slow down the deposit of harmful cholesterol on the artery walls.”Guinness ran an advertising campaign in the 1920s which stemmed from market research – when people told the company that they felt good after their pint, the slogan, created by Dorothy L. Sayers–”Guinness is Good for You”. Advertising for alcoholic drinks that implies improved physical performance or enhanced personal qualities is now prohibited in Ireland.Diageo, the company that now manufactures Guinness, says: “We never make any medical claims for our drinks.”

38cm x 57cm Arthur Guinness started brewing ales in 1759 at the St James Gate Brewery,Dublin.On 31st December 1759 he signed a 9,000 year lease at £45 per annum for the unused brewery.Ten years later, on 19 May 1769, Guinness first exported his ale: he shipped six-and-a-half barrels to Great Britain before he started selling the dark beer porter in 1778. The first Guinness beers to use the term were Single Stout and Double Stout in the 1840s.Throughout the bulk of its history, Guinness produced only three variations of a single beer type: porter or single stout, double or extra and foreign stout for export. “Stout” originally referred to a beer’s strength, but eventually shifted meaning toward body and colour.Porter was also referred to as “plain”, as mentioned in the famous refrain of Flann O’Brien‘s poem “The Workman’s Friend”: “A pint of plain is your only man.” Already one of the top-three British and Irish brewers, Guinness’s sales soared from 350,000 barrels in 1868 to 779,000 barrels in 1876.In October 1886 Guinness became a public company, and was averaging sales of 1,138,000 barrels a year. This was despite the brewery’s refusal to either advertise or offer its beer at a discount. Even though Guinness owned no public houses, the company was valued at £6 million and shares were twenty times oversubscribed, with share prices rising to a 60 per cent premium on the first day of trading. The breweries pioneered several quality control efforts. The brewery hired the statistician William Sealy Gosset in 1899, who achieved lasting fame under the pseudonym “Student” for techniques developed for Guinness, particularly Student’s t-distribution and the even more commonly known Student’s t-test. By 1900 the brewery was operating unparalleled welfare schemes for its 5,000 employees. By 1907 the welfare schemes were costing the brewery £40,000 a year, which was one-fifth of the total wages bill. The improvements were suggested and supervised by Sir John Lumsden. By 1914, Guinness was producing 2,652,000 barrels of beer a year, which was more than double that of its nearest competitor Bass, and was supplying more than 10 per cent of the total UK beer market. In the 1930s, Guinness became the seventh largest company in the world. Before 1939, if a Guinness brewer wished to marry a Catholic, his resignation was requested. According to Thomas Molloy, writing in the Irish Independent, “It had no qualms about selling drink to Catholics but it did everything it could to avoid employing them until the 1960s.” Guinness thought they brewed their last porter in 1973. In the 1970s, following declining sales, the decision was taken to make Guinness Extra Stout more “drinkable”. The gravity was subsequently reduced, and the brand was relaunched in 1981. Pale malt was used for the first time, and isomerized hop extract began to be used. In 2014, two new porters were introduced: West Indies Porter and Dublin Porter. Guinness acquired the Distillers Company in 1986.This led to a scandal and criminal trialconcerning the artificial inflation of the Guinness share price during the takeover bid engineered by the chairman, Ernest Saunders. A subsequent £5.2 million success fee paid to an American lawyer and Guinness director, Tom Ward, was the subject of the case Guinness plc v Saunders, in which the House of Lords declared that the payment had been invalid. In the 1980s, as the IRA’s bombing campaign spread to London and the rest of Britain, Guinness considered scrapping the Harp as its logo. The company merged with Grand Metropolitan in 1997 to form Diageo. Due to controversy over the merger, the company was maintained as a separate entity within Diageo and has retained the rights to the product and all associated trademarks of Guinness.The Guinness brewery in Park Royal, London closed in 2005. The production of all Guinness sold in the UK and Ireland was moved to St. James’s Gate Brewery, Dublin. Guinness has also been referred to as “that black stuff”. Guinness had a fleet of ships, barges and yachts. The Irish Sunday Independent newspaper reported on 17 June 2007 that Diageo intended to close the historic St James’s Gate plant in Dublin and move to a greenfield site on the outskirts of the city.This news caused some controversy when it was announced.The following day, the Irish Daily Mail ran a follow-up story with a double page spread complete with images and a history of the plant since 1759. Initially, Diageo said that talk of a move was pure speculation but in the face of mounting speculation in the wake of the Sunday Independent article, the company confirmed that it is undertaking a “significant review of its operations”. This review was largely due to the efforts of the company’s ongoing drive to reduce the environmental impact of brewing at the St James’s Gate plant. On 23 November 2007, an article appeared in the Evening Herald, a Dublin newspaper, stating that the Dublin City Council, in the best interests of the city of Dublin, had put forward a motion to prevent planning permission ever being granted for development of the site, thus making it very difficult for Diageo to sell off the site for residential development. On 9 May 2008, Diageo announced that the St James’s Gate brewery will remain open and undergo renovations, but that breweries in Kilkenny and Dundalk will be closed by 2013 when a new larger brewery is opened near Dublin. The result will be a loss of roughly 250 jobs across the entire Diageo/Guinness workforce in Ireland.Two days later, the Sunday Independent again reported that Diageo chiefs had met with Tánaiste Mary Coughlan, the deputy leader of the Government of Ireland, about moving operations to Ireland from the UK to benefit from its lower corporation tax rates. Several UK firms have made the move in order to pay Ireland’s 12.5 per cent rate rather than the UK’s 28 per cent rate. Diageo released a statement to the London stock exchange denying the report.Despite the merger that created Diageo plc in 1997, Guinness has retained its right to the Guinness brand and associated trademarks and thus continues to trade under the traditional Guinness name despite trading under the corporation name Diageo for a brief period in 1997. In November 2015 it was announced that Guinness are planning to make their beer suitable for consumption by vegetarians and vegans by the end of 2016 through the introduction of a new filtration process at their existing Guinness Brewery that avoids the need to use isinglass from fish bladders to filter out yeast particles.This went into effect in 2017, per the company’s FAQ webpage where they state: “Our new filtration process has removed the use of isinglass as a means of filtration and vegans can now enjoy a pint of Guinness. All Guinness Draught in keg format is brewed without using isinglass. Full distribution of bottle and can formats will be in place by the end of 2017, so until then, our advice to vegans is to consume the product from the keg format only for now. Guinness stout is made from water, barley, roast malt extract, hops, and brewer’s yeast. A portion of the barley is roasted to give Guinness its dark colour and characteristic taste. It is pasteurisedand filtered. Until the late 1950s Guinness was still racked into wooden casks. In the late 1950s and early 1960s, Guinness ceased brewing cask-conditioned beers and developed a keg brewing system with aluminium kegs replacing the wooden casks; these were nicknamed “iron lungs”.Until 2016 the production of Guinness, as with many beers, involved the use of isinglass made from fish. Isinglass was used as a fining agent for settling out suspended matter in the vat. The isinglass was retained in the floor of the vat but it was possible that minute quantities might be carried over into the beer. Diageo announced in February 2018 that the use of isinglass in draught Guinness was to be discontinued and an alternative clarification agent would be used instead. This has made draught Guinness acceptable to vegans and vegetarians. Arguably its biggest change to date, in 1959 Guinness began using nitrogen, which changed the fundamental texture and flavour of the Guinness of the past as nitrogen bubbles are much smaller than CO2, giving a “creamier” and “smoother” consistency over a sharper and traditional CO2 taste. This step was taken after Michael Ash – a mathematician turned brewer – discovered the mechanism to make this possible. Nitrogen is less soluble than carbon dioxide, which allows the beer to be put under high pressure without making it fizzy. High pressure of the dissolved gas is required to enable very small bubbles to be formed by forcing the draught beer through fine holes in a plate in the tap, which causes the characteristic “surge” (the widget in cans and bottles achieves the same effect). This “widget” is a small plastic ball containing the nitrogen. The perceived smoothness of draught Guinness is due to its low level of carbon dioxide and the creaminess of the head caused by the very fine bubbles that arise from the use of nitrogen and the dispensing method described above. “Foreign Extra Stout” contains more carbon dioxide, causing a more acidic taste. Contemporary Guinness Draught and Extra Stout are weaker than they were in the 19th century, when they had an original gravity of over 1.070. Foreign Extra Stout and Special Export Stout, with abv of 7.5% and 9% respectively, are perhaps closest to the original in character.Although Guinness may appear to be black, it is officially a very dark shade of ruby. The most recent change in alcohol content from the Import Stout to the Extra Stout was due to a change in distribution through North American market. Consumer complaints have influenced recent distribution and bottle changes. Studies claim that Guinness can be beneficial to the heart. Researchers found that “‘antioxidantcompounds’ in the Guinness, similar to those found in certain fruits and vegetables, are responsible for the health benefits because they slow down the deposit of harmful cholesterol on the artery walls.”Guinness ran an advertising campaign in the 1920s which stemmed from market research – when people told the company that they felt good after their pint, the slogan, created by Dorothy L. Sayers–”Guinness is Good for You”. Advertising for alcoholic drinks that implies improved physical performance or enhanced personal qualities is now prohibited in Ireland.Diageo, the company that now manufactures Guinness, says: “We never make any medical claims for our drinks.” -

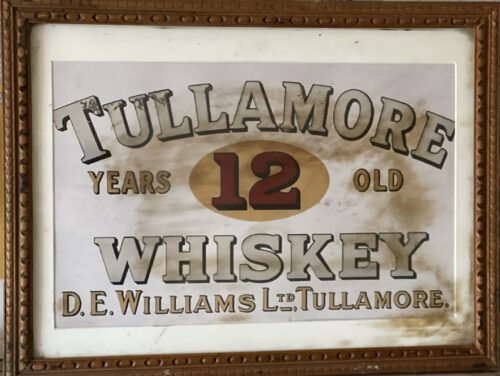

55cm x 45cm Banagher Co Offaly Tullamore D.E.W. is a brand of Irish whiskey produced by William Grant & Sons. It is the second largest selling brand of Irish whiskey globally, with sales of over 950,000 cases per annum as of 2015.The whiskey was originally produced in the Tullamore, County Offaly, Ireland, at the old Tullamore Distillery which was established in 1829. Its name is derived from the initials of Daniel E. Williams (D.E.W.), a general manager and later owner of the original distillery. In 1954, the original distillery closed down, and with stocks of whiskey running low, the brand was sold to John Powers & Son, another Irish distiller in the 1960s, with production transferred to the Midleton Distillery, County Cork in the 1970s following a merger of three major Irish distillers.In 2010, the brand was purchased by William Grant & Sons, who constructed a new distillery on the outskirts of Tullamore. The new distillery opened in 2014, bringing production of the whiskey back to the town after a break of sixty years.

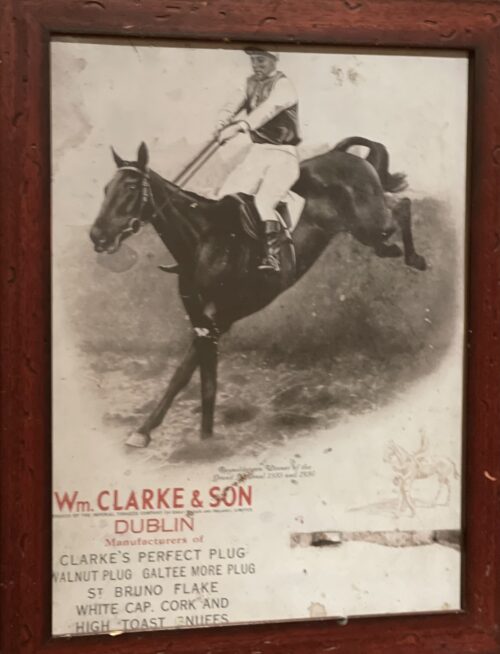

55cm x 45cm Banagher Co Offaly Tullamore D.E.W. is a brand of Irish whiskey produced by William Grant & Sons. It is the second largest selling brand of Irish whiskey globally, with sales of over 950,000 cases per annum as of 2015.The whiskey was originally produced in the Tullamore, County Offaly, Ireland, at the old Tullamore Distillery which was established in 1829. Its name is derived from the initials of Daniel E. Williams (D.E.W.), a general manager and later owner of the original distillery. In 1954, the original distillery closed down, and with stocks of whiskey running low, the brand was sold to John Powers & Son, another Irish distiller in the 1960s, with production transferred to the Midleton Distillery, County Cork in the 1970s following a merger of three major Irish distillers.In 2010, the brand was purchased by William Grant & Sons, who constructed a new distillery on the outskirts of Tullamore. The new distillery opened in 2014, bringing production of the whiskey back to the town after a break of sixty years.Mick The Miller,as featured in this iconic advert, was the most famous greyhound of all time. He was born in 1926 in the village of Killeigh, County Offaly, Ireland at Millbrook House(only 5 miles from Tullamore), the home of parish curate, Fr Martin Brophy. When he was born Mick was the runt of the litter but Michael Greene, who worked for Fr Brophy, singled the little pup out as a future champion and insisted that he be allowed to rear him. With constant attention and regular exercise Mick The Miller developed into a racing machine. His first forays were on local coursing fields where he had some success but he showed his real talent on the track where he won 15 of his first 20 races.

.jpg)

In 1929 Fr Brophy decided to try Mick in English Greyhound Derby at White City, London. On his first trial-run, Mick equalled the track record. Then, in his first heat, he broke the world record, becoming the first greyhound ever to run 525 yards in under 30 seconds. Fr Brophy was inundated with offers and sold him to Albert Williams. Mick went on to win the 1929 Derby. Within a year he had changed hands again to Arundel H Kempton and won the Derby for a second time.

Over the course of his English career he won 36 of his 48 races, including the Derby (twice), the St Leger, the Cesarewitch, and the Welsh Derby. He set six new world records and two new track records. He was the first greyhound to win 19 races in a row. Several of his records went unbroken for over 40 years. He won, in total, almost £10,000 in prizemoney. But he also became the poster-dog for greyhound racing. He was a celebrity on a par with any sports person, muscisian or moviestar. The more famous he became, the more he attracted people to greyhound racing. Thousands thronged to watch him, providing a huge boost to the sport. It is said that he actually saved the sport of greyhound racing.

After retirement to stud his popularity continued. He starred in the film Wild Boy (based on his life-story) in 1934 which was shown in cinemas all across the UK. He was in huge demand on the celebrity circuit, opening shops, attending big races and even rubbing shoulder with royalty (such as the King and Queen) at charity events. When he died in 1939 aged 12, his owner donated his body to the British Natural History Museum in London. And Mick`s fame has continued ever since. In 1981 he was inducted into the American Hall of Fame (International Section). In 1990 English author Michael Tanner published a book, Mick The Miller - Sporting Icon Of the Depression. And in 2011 the people of Killeigh erected a monument on the village green to honour their most famous son. Mick The Miller is not just the most famous greyhound of all time but one of the most loved dogs that has ever lived.

-

47cm x 34cm Arthur Guinness started brewing ales in 1759 at the St James Gate Brewery,Dublin.On 31st December 1759 he signed a 9,000 year lease at £45 per annum for the unused brewery.Ten years later, on 19 May 1769, Guinness first exported his ale: he shipped six-and-a-half barrels to Great Britain before he started selling the dark beer porter in 1778. The first Guinness beers to use the term were Single Stout and Double Stout in the 1840s.Throughout the bulk of its history, Guinness produced only three variations of a single beer type: porter or single stout, double or extra and foreign stout for export. “Stout” originally referred to a beer’s strength, but eventually shifted meaning toward body and colour.Porter was also referred to as “plain”, as mentioned in the famous refrain of Flann O’Brien‘s poem “The Workman’s Friend”: “A pint of plain is your only man.” Already one of the top-three British and Irish brewers, Guinness’s sales soared from 350,000 barrels in 1868 to 779,000 barrels in 1876.In October 1886 Guinness became a public company, and was averaging sales of 1,138,000 barrels a year. This was despite the brewery’s refusal to either advertise or offer its beer at a discount. Even though Guinness owned no public houses, the company was valued at £6 million and shares were twenty times oversubscribed, with share prices rising to a 60 per cent premium on the first day of trading. The breweries pioneered several quality control efforts. The brewery hired the statistician William Sealy Gosset in 1899, who achieved lasting fame under the pseudonym “Student” for techniques developed for Guinness, particularly Student’s t-distribution and the even more commonly known Student’s t-test. By 1900 the brewery was operating unparalleled welfare schemes for its 5,000 employees. By 1907 the welfare schemes were costing the brewery £40,000 a year, which was one-fifth of the total wages bill. The improvements were suggested and supervised by Sir John Lumsden. By 1914, Guinness was producing 2,652,000 barrels of beer a year, which was more than double that of its nearest competitor Bass, and was supplying more than 10 per cent of the total UK beer market. In the 1930s, Guinness became the seventh largest company in the world. Before 1939, if a Guinness brewer wished to marry a Catholic, his resignation was requested. According to Thomas Molloy, writing in the Irish Independent, “It had no qualms about selling drink to Catholics but it did everything it could to avoid employing them until the 1960s.” Guinness thought they brewed their last porter in 1973. In the 1970s, following declining sales, the decision was taken to make Guinness Extra Stout more “drinkable”. The gravity was subsequently reduced, and the brand was relaunched in 1981. Pale malt was used for the first time, and isomerized hop extract began to be used. In 2014, two new porters were introduced: West Indies Porter and Dublin Porter. Guinness acquired the Distillers Company in 1986.This led to a scandal and criminal trialconcerning the artificial inflation of the Guinness share price during the takeover bid engineered by the chairman, Ernest Saunders. A subsequent £5.2 million success fee paid to an American lawyer and Guinness director, Tom Ward, was the subject of the case Guinness plc v Saunders, in which the House of Lords declared that the payment had been invalid. In the 1980s, as the IRA’s bombing campaign spread to London and the rest of Britain, Guinness considered scrapping the Harp as its logo. The company merged with Grand Metropolitan in 1997 to form Diageo. Due to controversy over the merger, the company was maintained as a separate entity within Diageo and has retained the rights to the product and all associated trademarks of Guinness.The Guinness brewery in Park Royal, London closed in 2005. The production of all Guinness sold in the UK and Ireland was moved to St. James’s Gate Brewery, Dublin. Guinness has also been referred to as “that black stuff”. Guinness had a fleet of ships, barges and yachts. The Irish Sunday Independent newspaper reported on 17 June 2007 that Diageo intended to close the historic St James’s Gate plant in Dublin and move to a greenfield site on the outskirts of the city.This news caused some controversy when it was announced.The following day, the Irish Daily Mail ran a follow-up story with a double page spread complete with images and a history of the plant since 1759. Initially, Diageo said that talk of a move was pure speculation but in the face of mounting speculation in the wake of the Sunday Independent article, the company confirmed that it is undertaking a “significant review of its operations”. This review was largely due to the efforts of the company’s ongoing drive to reduce the environmental impact of brewing at the St James’s Gate plant. On 23 November 2007, an article appeared in the Evening Herald, a Dublin newspaper, stating that the Dublin City Council, in the best interests of the city of Dublin, had put forward a motion to prevent planning permission ever being granted for development of the site, thus making it very difficult for Diageo to sell off the site for residential development. On 9 May 2008, Diageo announced that the St James’s Gate brewery will remain open and undergo renovations, but that breweries in Kilkenny and Dundalk will be closed by 2013 when a new larger brewery is opened near Dublin. The result will be a loss of roughly 250 jobs across the entire Diageo/Guinness workforce in Ireland.Two days later, the Sunday Independent again reported that Diageo chiefs had met with Tánaiste Mary Coughlan, the deputy leader of the Government of Ireland, about moving operations to Ireland from the UK to benefit from its lower corporation tax rates. Several UK firms have made the move in order to pay Ireland’s 12.5 per cent rate rather than the UK’s 28 per cent rate. Diageo released a statement to the London stock exchange denying the report.Despite the merger that created Diageo plc in 1997, Guinness has retained its right to the Guinness brand and associated trademarks and thus continues to trade under the traditional Guinness name despite trading under the corporation name Diageo for a brief period in 1997. In November 2015 it was announced that Guinness are planning to make their beer suitable for consumption by vegetarians and vegans by the end of 2016 through the introduction of a new filtration process at their existing Guinness Brewery that avoids the need to use isinglass from fish bladders to filter out yeast particles.This went into effect in 2017, per the company’s FAQ webpage where they state: “Our new filtration process has removed the use of isinglass as a means of filtration and vegans can now enjoy a pint of Guinness. All Guinness Draught in keg format is brewed without using isinglass. Full distribution of bottle and can formats will be in place by the end of 2017, so until then, our advice to vegans is to consume the product from the keg format only for now. Guinness stout is made from water, barley, roast malt extract, hops, and brewer’s yeast. A portion of the barley is roasted to give Guinness its dark colour and characteristic taste. It is pasteurisedand filtered. Until the late 1950s Guinness was still racked into wooden casks. In the late 1950s and early 1960s, Guinness ceased brewing cask-conditioned beers and developed a keg brewing system with aluminium kegs replacing the wooden casks; these were nicknamed “iron lungs”.Until 2016 the production of Guinness, as with many beers, involved the use of isinglass made from fish. Isinglass was used as a fining agent for settling out suspended matter in the vat. The isinglass was retained in the floor of the vat but it was possible that minute quantities might be carried over into the beer. Diageo announced in February 2018 that the use of isinglass in draught Guinness was to be discontinued and an alternative clarification agent would be used instead. This has made draught Guinness acceptable to vegans and vegetarians. Arguably its biggest change to date, in 1959 Guinness began using nitrogen, which changed the fundamental texture and flavour of the Guinness of the past as nitrogen bubbles are much smaller than CO2, giving a “creamier” and “smoother” consistency over a sharper and traditional CO2 taste. This step was taken after Michael Ash – a mathematician turned brewer – discovered the mechanism to make this possible. Nitrogen is less soluble than carbon dioxide, which allows the beer to be put under high pressure without making it fizzy. High pressure of the dissolved gas is required to enable very small bubbles to be formed by forcing the draught beer through fine holes in a plate in the tap, which causes the characteristic “surge” (the widget in cans and bottles achieves the same effect). This “widget” is a small plastic ball containing the nitrogen. The perceived smoothness of draught Guinness is due to its low level of carbon dioxide and the creaminess of the head caused by the very fine bubbles that arise from the use of nitrogen and the dispensing method described above. “Foreign Extra Stout” contains more carbon dioxide, causing a more acidic taste. Contemporary Guinness Draught and Extra Stout are weaker than they were in the 19th century, when they had an original gravity of over 1.070. Foreign Extra Stout and Special Export Stout, with abv of 7.5% and 9% respectively, are perhaps closest to the original in character.Although Guinness may appear to be black, it is officially a very dark shade of ruby. The most recent change in alcohol content from the Import Stout to the Extra Stout was due to a change in distribution through North American market. Consumer complaints have influenced recent distribution and bottle changes. Studies claim that Guinness can be beneficial to the heart. Researchers found that “‘antioxidantcompounds’ in the Guinness, similar to those found in certain fruits and vegetables, are responsible for the health benefits because they slow down the deposit of harmful cholesterol on the artery walls.”Guinness ran an advertising campaign in the 1920s which stemmed from market research – when people told the company that they felt good after their pint, the slogan, created by Dorothy L. Sayers–”Guinness is Good for You”. Advertising for alcoholic drinks that implies improved physical performance or enhanced personal qualities is now prohibited in Ireland.Diageo, the company that now manufactures Guinness, says: “We never make any medical claims for our drinks.”

47cm x 34cm Arthur Guinness started brewing ales in 1759 at the St James Gate Brewery,Dublin.On 31st December 1759 he signed a 9,000 year lease at £45 per annum for the unused brewery.Ten years later, on 19 May 1769, Guinness first exported his ale: he shipped six-and-a-half barrels to Great Britain before he started selling the dark beer porter in 1778. The first Guinness beers to use the term were Single Stout and Double Stout in the 1840s.Throughout the bulk of its history, Guinness produced only three variations of a single beer type: porter or single stout, double or extra and foreign stout for export. “Stout” originally referred to a beer’s strength, but eventually shifted meaning toward body and colour.Porter was also referred to as “plain”, as mentioned in the famous refrain of Flann O’Brien‘s poem “The Workman’s Friend”: “A pint of plain is your only man.” Already one of the top-three British and Irish brewers, Guinness’s sales soared from 350,000 barrels in 1868 to 779,000 barrels in 1876.In October 1886 Guinness became a public company, and was averaging sales of 1,138,000 barrels a year. This was despite the brewery’s refusal to either advertise or offer its beer at a discount. Even though Guinness owned no public houses, the company was valued at £6 million and shares were twenty times oversubscribed, with share prices rising to a 60 per cent premium on the first day of trading. The breweries pioneered several quality control efforts. The brewery hired the statistician William Sealy Gosset in 1899, who achieved lasting fame under the pseudonym “Student” for techniques developed for Guinness, particularly Student’s t-distribution and the even more commonly known Student’s t-test. By 1900 the brewery was operating unparalleled welfare schemes for its 5,000 employees. By 1907 the welfare schemes were costing the brewery £40,000 a year, which was one-fifth of the total wages bill. The improvements were suggested and supervised by Sir John Lumsden. By 1914, Guinness was producing 2,652,000 barrels of beer a year, which was more than double that of its nearest competitor Bass, and was supplying more than 10 per cent of the total UK beer market. In the 1930s, Guinness became the seventh largest company in the world. Before 1939, if a Guinness brewer wished to marry a Catholic, his resignation was requested. According to Thomas Molloy, writing in the Irish Independent, “It had no qualms about selling drink to Catholics but it did everything it could to avoid employing them until the 1960s.” Guinness thought they brewed their last porter in 1973. In the 1970s, following declining sales, the decision was taken to make Guinness Extra Stout more “drinkable”. The gravity was subsequently reduced, and the brand was relaunched in 1981. Pale malt was used for the first time, and isomerized hop extract began to be used. In 2014, two new porters were introduced: West Indies Porter and Dublin Porter. Guinness acquired the Distillers Company in 1986.This led to a scandal and criminal trialconcerning the artificial inflation of the Guinness share price during the takeover bid engineered by the chairman, Ernest Saunders. A subsequent £5.2 million success fee paid to an American lawyer and Guinness director, Tom Ward, was the subject of the case Guinness plc v Saunders, in which the House of Lords declared that the payment had been invalid. In the 1980s, as the IRA’s bombing campaign spread to London and the rest of Britain, Guinness considered scrapping the Harp as its logo. The company merged with Grand Metropolitan in 1997 to form Diageo. Due to controversy over the merger, the company was maintained as a separate entity within Diageo and has retained the rights to the product and all associated trademarks of Guinness.The Guinness brewery in Park Royal, London closed in 2005. The production of all Guinness sold in the UK and Ireland was moved to St. James’s Gate Brewery, Dublin. Guinness has also been referred to as “that black stuff”. Guinness had a fleet of ships, barges and yachts. The Irish Sunday Independent newspaper reported on 17 June 2007 that Diageo intended to close the historic St James’s Gate plant in Dublin and move to a greenfield site on the outskirts of the city.This news caused some controversy when it was announced.The following day, the Irish Daily Mail ran a follow-up story with a double page spread complete with images and a history of the plant since 1759. Initially, Diageo said that talk of a move was pure speculation but in the face of mounting speculation in the wake of the Sunday Independent article, the company confirmed that it is undertaking a “significant review of its operations”. This review was largely due to the efforts of the company’s ongoing drive to reduce the environmental impact of brewing at the St James’s Gate plant. On 23 November 2007, an article appeared in the Evening Herald, a Dublin newspaper, stating that the Dublin City Council, in the best interests of the city of Dublin, had put forward a motion to prevent planning permission ever being granted for development of the site, thus making it very difficult for Diageo to sell off the site for residential development. On 9 May 2008, Diageo announced that the St James’s Gate brewery will remain open and undergo renovations, but that breweries in Kilkenny and Dundalk will be closed by 2013 when a new larger brewery is opened near Dublin. The result will be a loss of roughly 250 jobs across the entire Diageo/Guinness workforce in Ireland.Two days later, the Sunday Independent again reported that Diageo chiefs had met with Tánaiste Mary Coughlan, the deputy leader of the Government of Ireland, about moving operations to Ireland from the UK to benefit from its lower corporation tax rates. Several UK firms have made the move in order to pay Ireland’s 12.5 per cent rate rather than the UK’s 28 per cent rate. Diageo released a statement to the London stock exchange denying the report.Despite the merger that created Diageo plc in 1997, Guinness has retained its right to the Guinness brand and associated trademarks and thus continues to trade under the traditional Guinness name despite trading under the corporation name Diageo for a brief period in 1997. In November 2015 it was announced that Guinness are planning to make their beer suitable for consumption by vegetarians and vegans by the end of 2016 through the introduction of a new filtration process at their existing Guinness Brewery that avoids the need to use isinglass from fish bladders to filter out yeast particles.This went into effect in 2017, per the company’s FAQ webpage where they state: “Our new filtration process has removed the use of isinglass as a means of filtration and vegans can now enjoy a pint of Guinness. All Guinness Draught in keg format is brewed without using isinglass. Full distribution of bottle and can formats will be in place by the end of 2017, so until then, our advice to vegans is to consume the product from the keg format only for now. Guinness stout is made from water, barley, roast malt extract, hops, and brewer’s yeast. A portion of the barley is roasted to give Guinness its dark colour and characteristic taste. It is pasteurisedand filtered. Until the late 1950s Guinness was still racked into wooden casks. In the late 1950s and early 1960s, Guinness ceased brewing cask-conditioned beers and developed a keg brewing system with aluminium kegs replacing the wooden casks; these were nicknamed “iron lungs”.Until 2016 the production of Guinness, as with many beers, involved the use of isinglass made from fish. Isinglass was used as a fining agent for settling out suspended matter in the vat. The isinglass was retained in the floor of the vat but it was possible that minute quantities might be carried over into the beer. Diageo announced in February 2018 that the use of isinglass in draught Guinness was to be discontinued and an alternative clarification agent would be used instead. This has made draught Guinness acceptable to vegans and vegetarians. Arguably its biggest change to date, in 1959 Guinness began using nitrogen, which changed the fundamental texture and flavour of the Guinness of the past as nitrogen bubbles are much smaller than CO2, giving a “creamier” and “smoother” consistency over a sharper and traditional CO2 taste. This step was taken after Michael Ash – a mathematician turned brewer – discovered the mechanism to make this possible. Nitrogen is less soluble than carbon dioxide, which allows the beer to be put under high pressure without making it fizzy. High pressure of the dissolved gas is required to enable very small bubbles to be formed by forcing the draught beer through fine holes in a plate in the tap, which causes the characteristic “surge” (the widget in cans and bottles achieves the same effect). This “widget” is a small plastic ball containing the nitrogen. The perceived smoothness of draught Guinness is due to its low level of carbon dioxide and the creaminess of the head caused by the very fine bubbles that arise from the use of nitrogen and the dispensing method described above. “Foreign Extra Stout” contains more carbon dioxide, causing a more acidic taste. Contemporary Guinness Draught and Extra Stout are weaker than they were in the 19th century, when they had an original gravity of over 1.070. Foreign Extra Stout and Special Export Stout, with abv of 7.5% and 9% respectively, are perhaps closest to the original in character.Although Guinness may appear to be black, it is officially a very dark shade of ruby. The most recent change in alcohol content from the Import Stout to the Extra Stout was due to a change in distribution through North American market. Consumer complaints have influenced recent distribution and bottle changes. Studies claim that Guinness can be beneficial to the heart. Researchers found that “‘antioxidantcompounds’ in the Guinness, similar to those found in certain fruits and vegetables, are responsible for the health benefits because they slow down the deposit of harmful cholesterol on the artery walls.”Guinness ran an advertising campaign in the 1920s which stemmed from market research – when people told the company that they felt good after their pint, the slogan, created by Dorothy L. Sayers–”Guinness is Good for You”. Advertising for alcoholic drinks that implies improved physical performance or enhanced personal qualities is now prohibited in Ireland.Diageo, the company that now manufactures Guinness, says: “We never make any medical claims for our drinks.” -

47cm x 35cm

The old Smithwicks brewery is on the site of a Franciscan abbey, where monks had brewed ale since the 14th century, and ruins of the original abbey still remain on its grounds. The old brewery has since been renovated and now hosts "The Smithwick's Experience Kilkenny" visitor attraction and centre.At the time of its closure, it was Ireland's oldest operating brewery.

John Smithwick was an orphan who had settled in Kilkenny. Shortly after his arrival, Smithwick went into the brewing business with Richard Cole on a piece of land that Cole had leased from the Duke of Ormond in 1705. Five years later, John Smithwick became the owner of the land. The brewery stayed small, servicing a loyal local following while John Smithwick diversified.

Following John Smithwick's death, the brewery temporarily fell out of family hands. John Smithwick's great grandson, Edmond bought the brewery land back freehold and worked to reshape its future. Edmond concentrated on discovering new markets and successfully building export trade. Drinkers in England, Scotland and Wales developed a taste for Smithwick's brews and output increased fivefold.

As a result of substantial contributions made to St Mary's Cathedral, Edmond became great friends with Irish liberal Daniel O'Connell, who later became godfather to one of his sons. Edmond Smithwick became well known and respected by the people of Kilkenny who elected him town mayor four times.

In 1800, export sales began to fall and the brewing industry encountered difficulty. To combat this, the Smithwick family increased production in their maltings, began selling mineral water and delivered butter with the ale from the back of their drays.By 1900, output was at an all-time low and the then owner James Smithwick was advised by auditors to shut the doors of the brewery. Instead, James reduced the range of beers they produced and set out to find new markets. He secured military contracts and soon after saw output increase again. James' son, Walter, took control in 1930 and steered the brewery to success through the hardships of both World War II and increasingly challenging weather conditions.By January 1950, Smithwick's was exporting ale to Boston.Smithwick's was purchased from Walter Smithwick in 1965 by Guinness and is now, along with Guinness, part of Diageo. Together, Guinness & Co. and Smithwick's developed and launched Smithwick's Draught Ale in 1966. By 1979, half a million barrels were sold each year.In 1980, Smithwick's began exporting to France. In 1993, Smithwick's Draught became Canada's leading imported ale.By 2010, Smithwick's continued to be brewed in Dundalk and Kilkenny with tankers sent to Dublin to be kegged for the on trade market. Cans and bottles were packaged by IBC in Belfast.Production in the Kilkenny brewery finished on 31 December 2013 and Smithwicks brands are now produced in the Diageo St.James' Gate brewery in Dublin.The original Kilkenny site was sold to Kilkenny County Council, with a small portion of the site dedicated to the opening of a visitor's centre, the "Smithwick's Experience Kilkenny".

47cm x 35cm

The old Smithwicks brewery is on the site of a Franciscan abbey, where monks had brewed ale since the 14th century, and ruins of the original abbey still remain on its grounds. The old brewery has since been renovated and now hosts "The Smithwick's Experience Kilkenny" visitor attraction and centre.At the time of its closure, it was Ireland's oldest operating brewery.

John Smithwick was an orphan who had settled in Kilkenny. Shortly after his arrival, Smithwick went into the brewing business with Richard Cole on a piece of land that Cole had leased from the Duke of Ormond in 1705. Five years later, John Smithwick became the owner of the land. The brewery stayed small, servicing a loyal local following while John Smithwick diversified.

Following John Smithwick's death, the brewery temporarily fell out of family hands. John Smithwick's great grandson, Edmond bought the brewery land back freehold and worked to reshape its future. Edmond concentrated on discovering new markets and successfully building export trade. Drinkers in England, Scotland and Wales developed a taste for Smithwick's brews and output increased fivefold.

As a result of substantial contributions made to St Mary's Cathedral, Edmond became great friends with Irish liberal Daniel O'Connell, who later became godfather to one of his sons. Edmond Smithwick became well known and respected by the people of Kilkenny who elected him town mayor four times.

In 1800, export sales began to fall and the brewing industry encountered difficulty. To combat this, the Smithwick family increased production in their maltings, began selling mineral water and delivered butter with the ale from the back of their drays.By 1900, output was at an all-time low and the then owner James Smithwick was advised by auditors to shut the doors of the brewery. Instead, James reduced the range of beers they produced and set out to find new markets. He secured military contracts and soon after saw output increase again. James' son, Walter, took control in 1930 and steered the brewery to success through the hardships of both World War II and increasingly challenging weather conditions.By January 1950, Smithwick's was exporting ale to Boston.Smithwick's was purchased from Walter Smithwick in 1965 by Guinness and is now, along with Guinness, part of Diageo. Together, Guinness & Co. and Smithwick's developed and launched Smithwick's Draught Ale in 1966. By 1979, half a million barrels were sold each year.In 1980, Smithwick's began exporting to France. In 1993, Smithwick's Draught became Canada's leading imported ale.By 2010, Smithwick's continued to be brewed in Dundalk and Kilkenny with tankers sent to Dublin to be kegged for the on trade market. Cans and bottles were packaged by IBC in Belfast.Production in the Kilkenny brewery finished on 31 December 2013 and Smithwicks brands are now produced in the Diageo St.James' Gate brewery in Dublin.The original Kilkenny site was sold to Kilkenny County Council, with a small portion of the site dedicated to the opening of a visitor's centre, the "Smithwick's Experience Kilkenny".

-

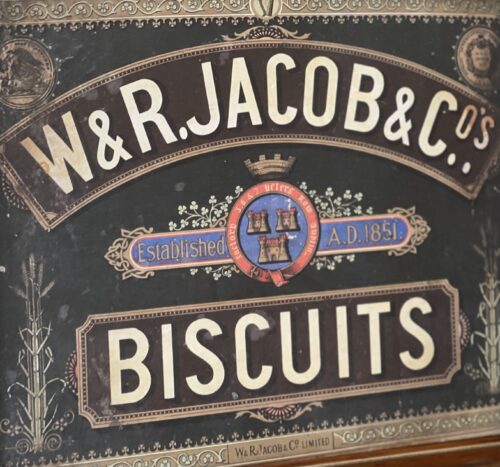

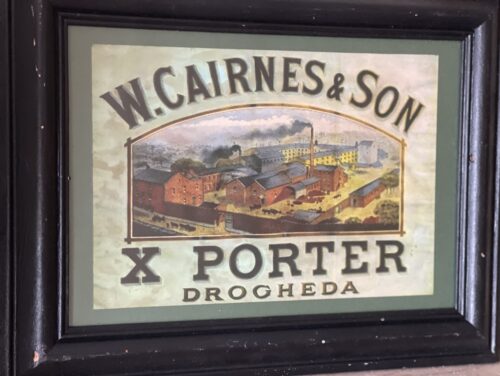

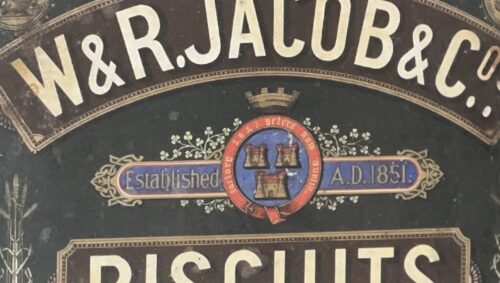

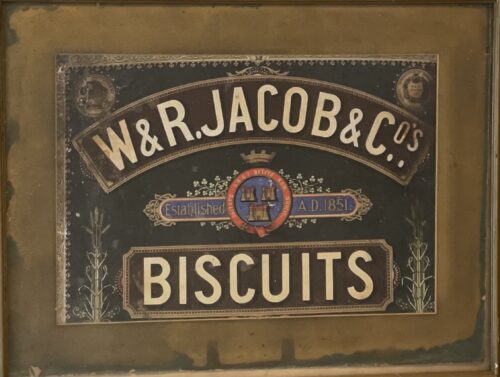

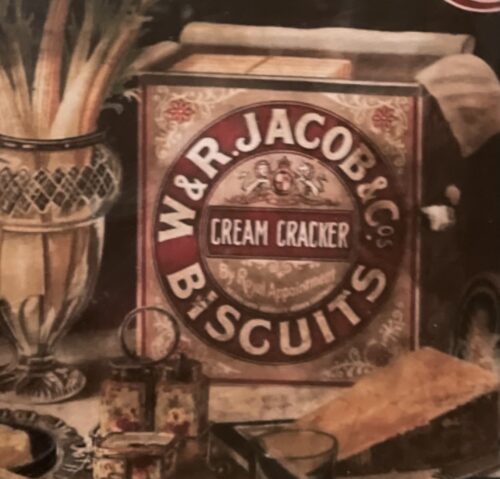

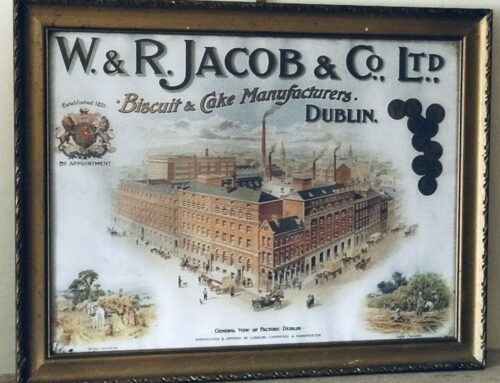

40cm x 34cm LimerickThe biscuit making firm of W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland.

40cm x 34cm LimerickThe biscuit making firm of W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland. -

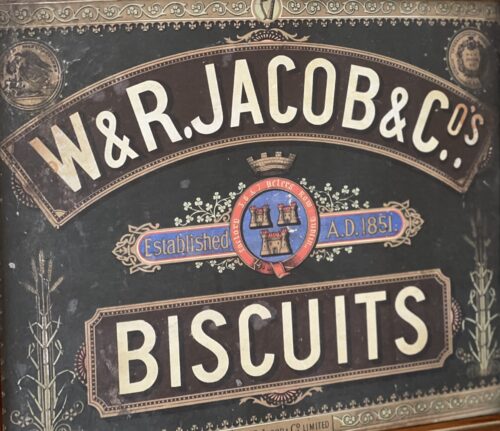

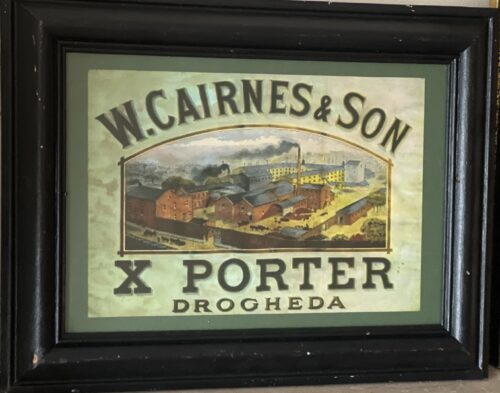

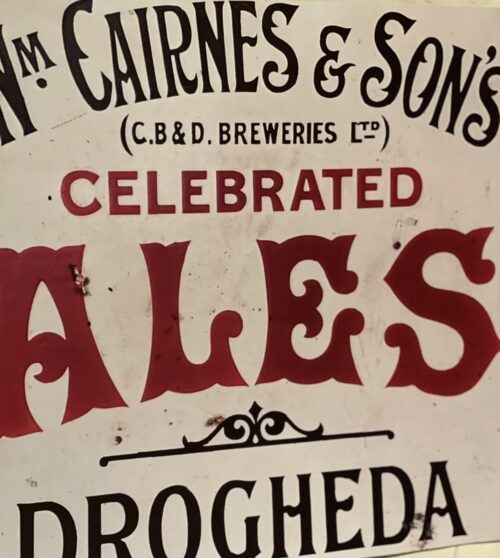

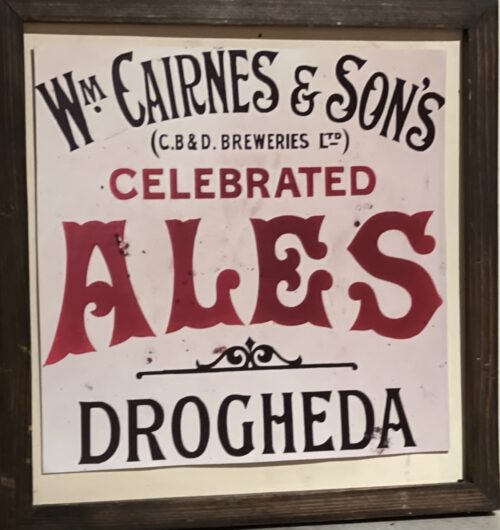

38cm x 30cm Drogheda W.Cairnes & Son Ltd, Drogheda, Co Louth, Ireland. Founded 1828 by William Cairnes. Registered April 1890 as the Castlebellingham & Drogheda Breweries Ltd. to acquire John Woolsey & Co. Ltd, Castlebellingham and William Cairnes & Son. Name changed as above in November 1933. Acquired by Guinness and ceased brewing in October 1959. From the Brewery History Society Journal Number 91 Founded in 1828 by William Cairnes with good markets in both Dublin and Belfast. In 1850 they extended their malt liquor portfolio to include porter. The brewery was closed in 1959 as part of a rationalisation plan when the Cherry-Cairnes partnership was dissolved, to be subsequently replaced by the Irish Ale Breweries Group, (a Guinness/Allied Breweries combination). Irish Ale Breweries was formally dissolved in 1988, becoming Guinness Ireland.

38cm x 30cm Drogheda W.Cairnes & Son Ltd, Drogheda, Co Louth, Ireland. Founded 1828 by William Cairnes. Registered April 1890 as the Castlebellingham & Drogheda Breweries Ltd. to acquire John Woolsey & Co. Ltd, Castlebellingham and William Cairnes & Son. Name changed as above in November 1933. Acquired by Guinness and ceased brewing in October 1959. From the Brewery History Society Journal Number 91 Founded in 1828 by William Cairnes with good markets in both Dublin and Belfast. In 1850 they extended their malt liquor portfolio to include porter. The brewery was closed in 1959 as part of a rationalisation plan when the Cherry-Cairnes partnership was dissolved, to be subsequently replaced by the Irish Ale Breweries Group, (a Guinness/Allied Breweries combination). Irish Ale Breweries was formally dissolved in 1988, becoming Guinness Ireland. -

42cm x 32cm Limerick The Jacobs Biscuit Bakery originated in Waterford in 1851,after being founded by William Beale Jacob and his brother Robert.It later moved to Bishop Street in Dublin with a further factory in Peters Row.Jacobs Bishop Street premises was occupied as a strategic location by rebels during the 1916 Easter Rebellion. W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland.

42cm x 32cm Limerick The Jacobs Biscuit Bakery originated in Waterford in 1851,after being founded by William Beale Jacob and his brother Robert.It later moved to Bishop Street in Dublin with a further factory in Peters Row.Jacobs Bishop Street premises was occupied as a strategic location by rebels during the 1916 Easter Rebellion. W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland. -

46cm x 39cm Limerick The Jacobs Biscuit Bakery originated in Waterford in 1851,after being founded by William Beale Jacob and his brother Robert.It later moved to Bishop Street in Dublin with a further factory in Peters Row.Jacobs Bishop Street premises was occupied as a strategic location by rebels during the 1916 Easter Rebellion. W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland.

46cm x 39cm Limerick The Jacobs Biscuit Bakery originated in Waterford in 1851,after being founded by William Beale Jacob and his brother Robert.It later moved to Bishop Street in Dublin with a further factory in Peters Row.Jacobs Bishop Street premises was occupied as a strategic location by rebels during the 1916 Easter Rebellion. W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland. -

42cm x 32cm Limerick The Jacobs Biscuit Bakery originated in Waterford in 1851,after being founded by William Beale Jacob and his brother Robert.It later moved to Bishop Street in Dublin with a further factory in Peters Row.Jacobs Bishop Street premises was occupied as a strategic location by rebels during the 1916 Easter Rebellion. W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland.

42cm x 32cm Limerick The Jacobs Biscuit Bakery originated in Waterford in 1851,after being founded by William Beale Jacob and his brother Robert.It later moved to Bishop Street in Dublin with a further factory in Peters Row.Jacobs Bishop Street premises was occupied as a strategic location by rebels during the 1916 Easter Rebellion. W. & R. Jacob's were one the largest employers in the Dublin of 1916, and their factory was seized on Easter Monday by perhaps 100 members of the 2nd Battalion of the Dublin Brigade of the Irish Volunteers under Thomas MacDonagh. The factory itself was an enormous and formidable Victorian edifice located on the 'block' enclosed by Bishop St, Bride St, Peter's St and Peter's Row, and between St Patrick's Cathedral and St Stephen's Green. Its seizure helped to complete a loop of building cross the south inner city; the factory had two large towers that could act as observation points, while its location was very close to both Camden St and Patrick St: natural routeways for troops entering the city centre from Portobello Barracks in Rathmines and Wellington Barracks on the South Circular Road. There were only a few staff present in the building when the Volunteers broke into it; a number of smaller outposts were established in the area around the factory. While the garrison saw some fighting early in the week, their principal enemies proved to be boredom and the locals: the factory was surrounded by tenements, and the Volunteers were attacked and abused by residents, many of whom were Jacob's workers themselves. The families of servicemen were also quite hostile, but there may have been another reason for this hostility: Michael O'Hanrahan, who was in Jacob's, expressed his concern that the choice of location might endanger local residents if the British chose to attack. As it happens, the factory was largely by-passed, though it was fired upon intermittently throughout the week by troops in Dublin Castle and elsewhere. MacDonagh surrendered in nearby St Patrick's Park on Sunday 30 April; some of the factory was looted after the Volunteers had left. Three members of the Jacob's garrison were executed. Most of the factory was eventually demolished, though fragments of the ground storey and one of the towers are still visible on Bishop St between the DIT campus on Aungier St and the National Archives of Ireland. -